Table of Contents

Production Planning Settings

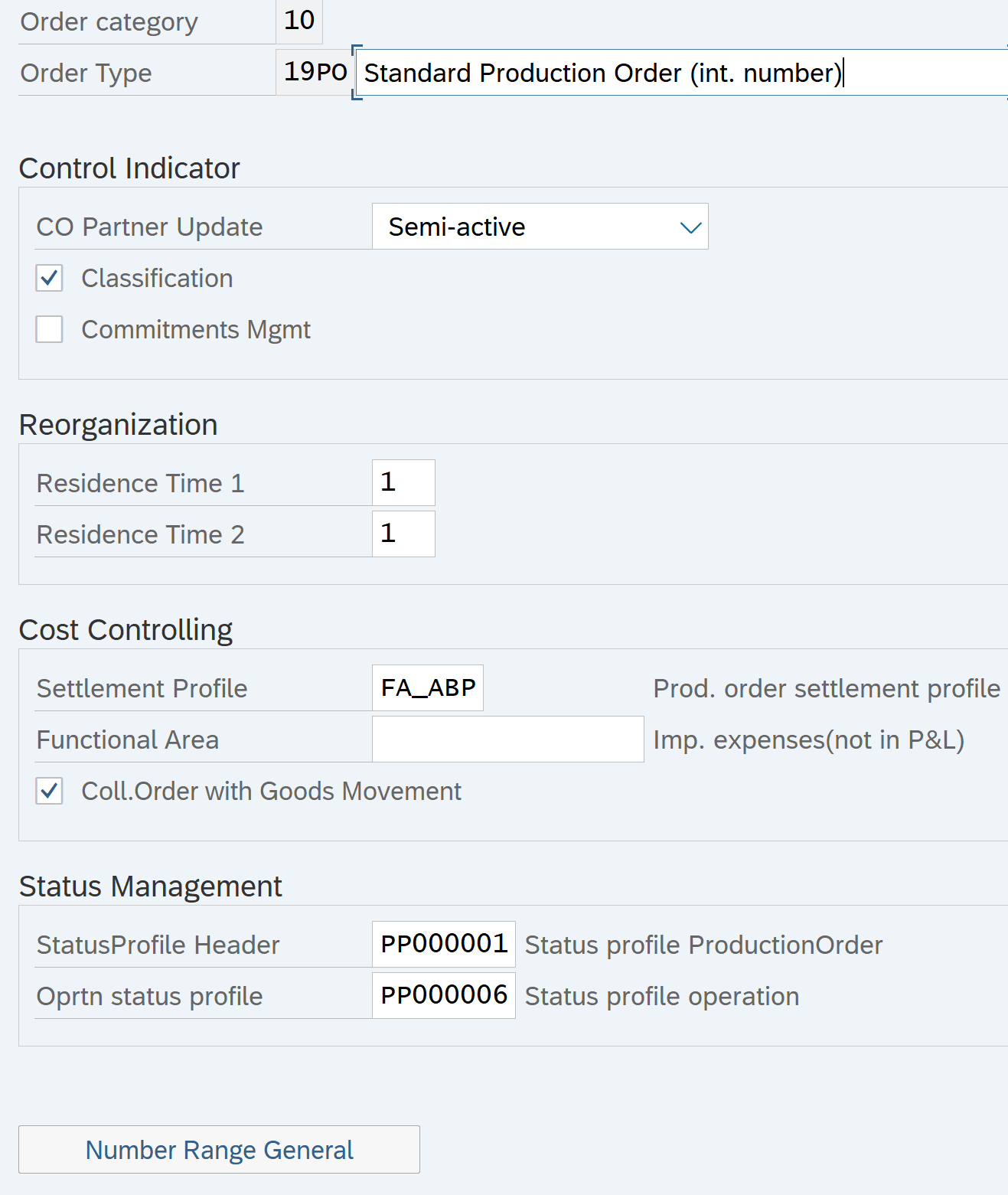

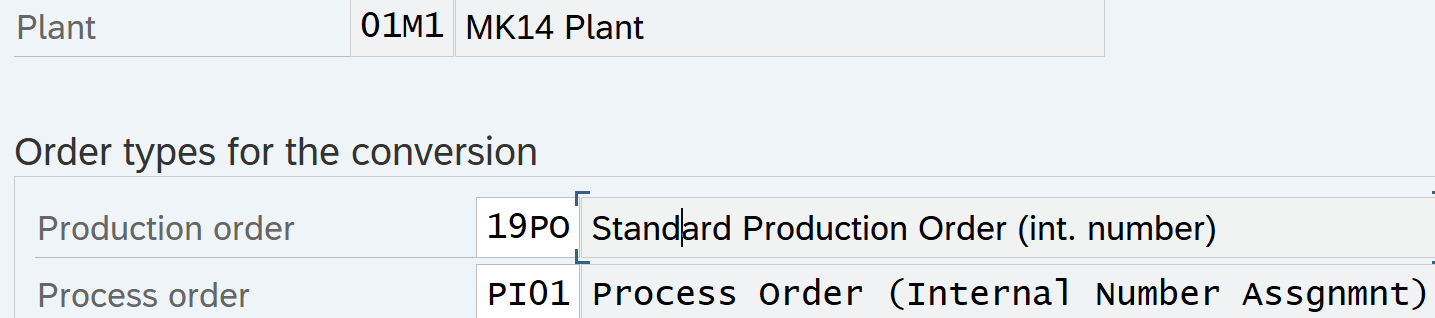

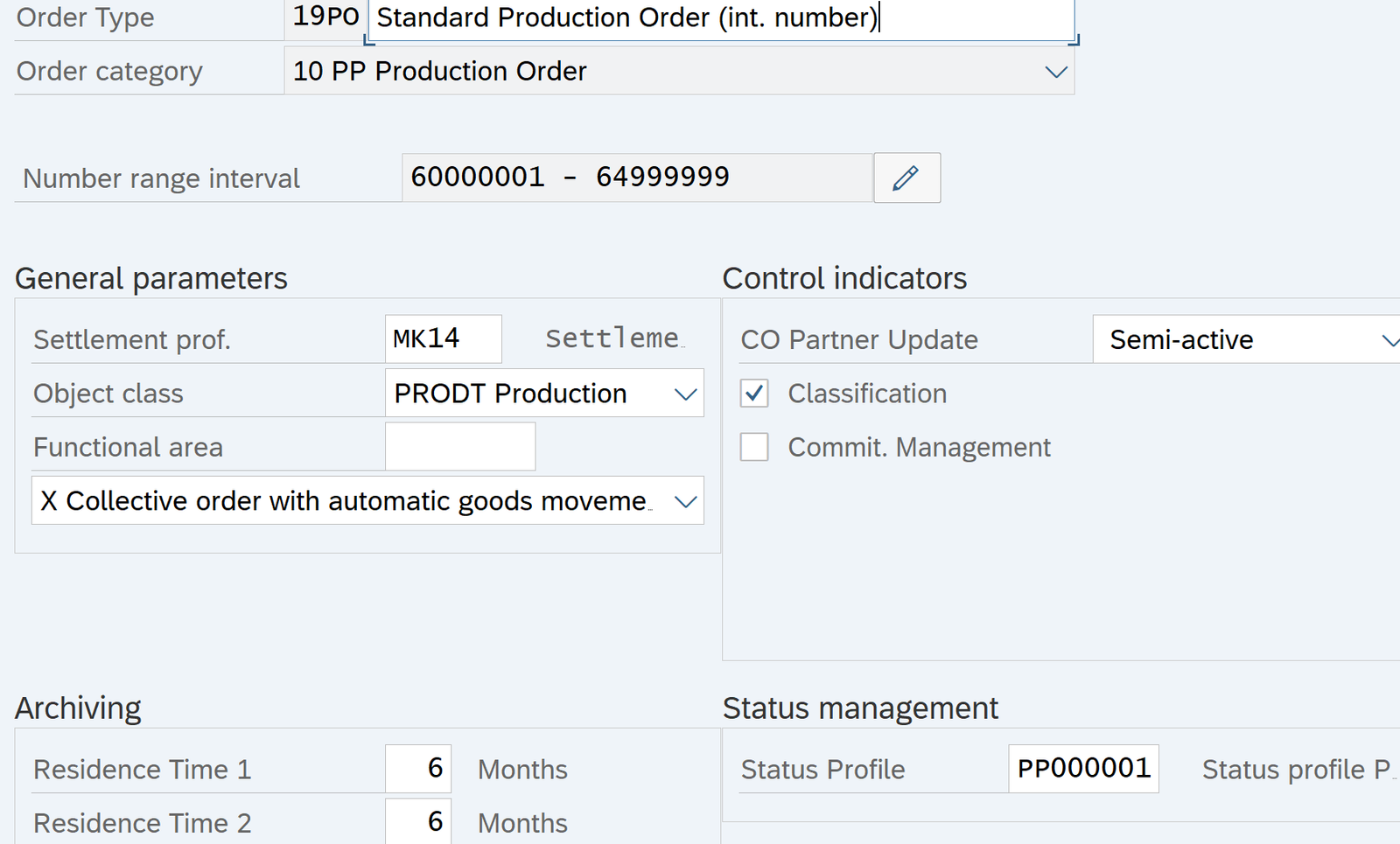

Define PP Order Type

Path: Production- Shop Floor control – master data – Order – define order type

Tcode: OPJH

Select PP01

Copy SAP standard Production order PP01 as 19PO

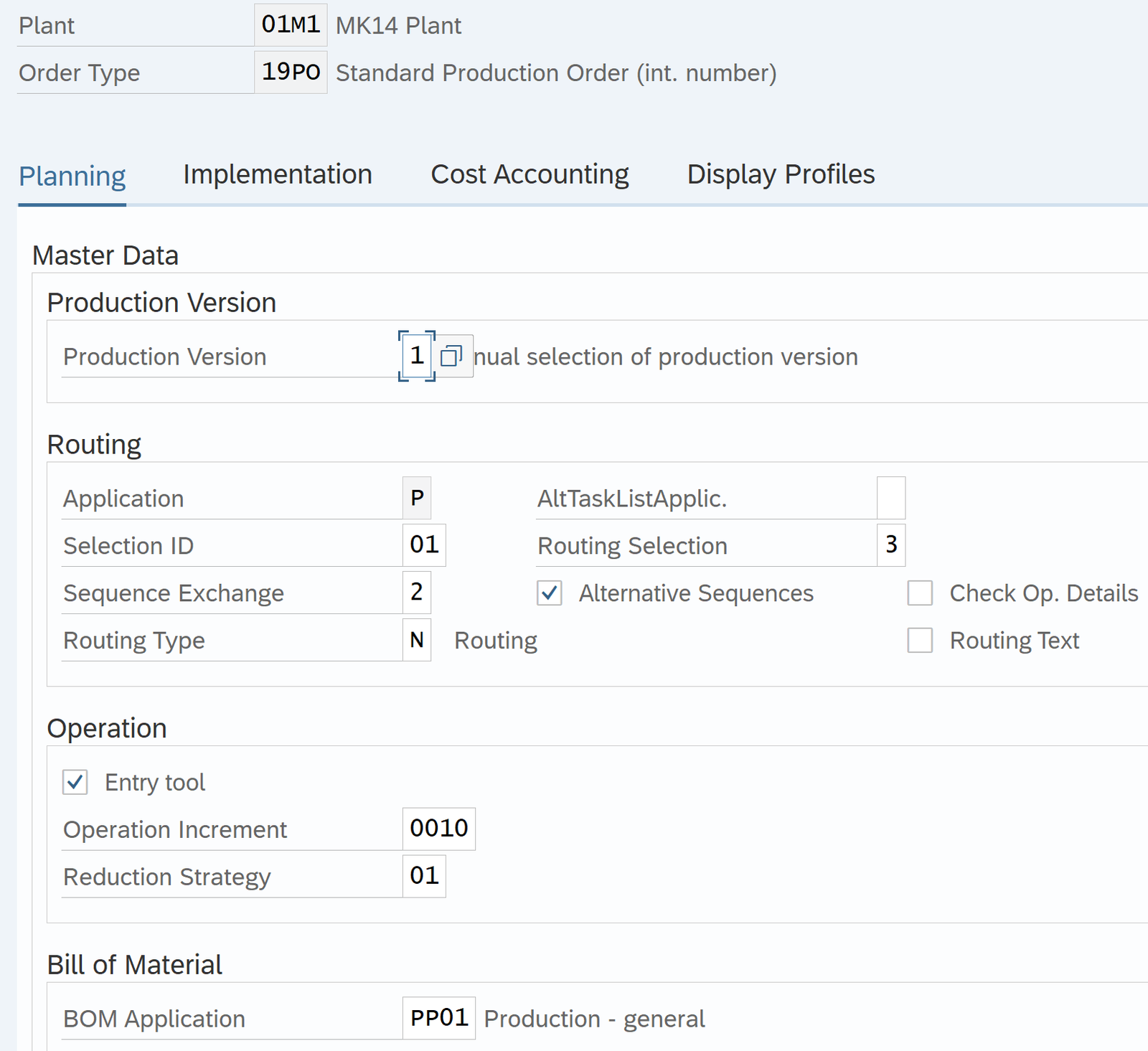

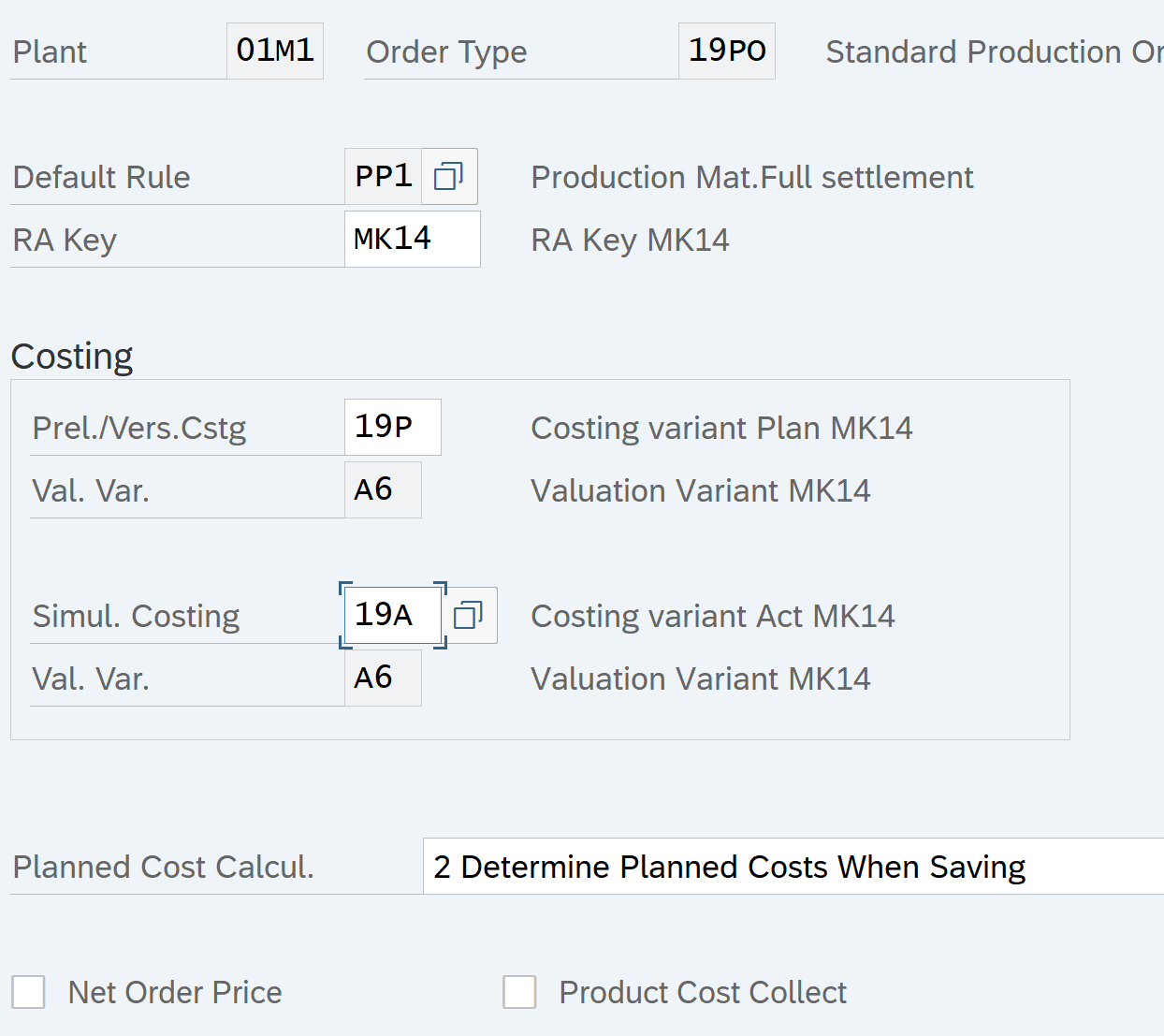

Define Order Type Dependent Parameters

Path: Production- Shop Floor control – master data – Order – define order type dependent parameters

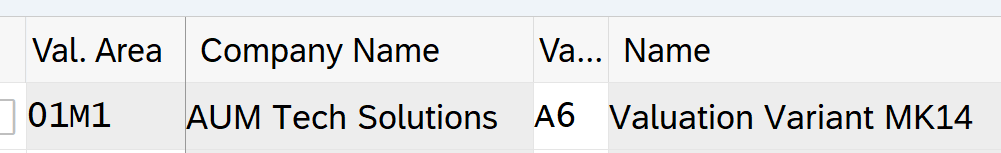

Tcode: OPL8

Copy from plant 1000 and Order type PP01. Change Plant to 01M1 and Order type to 19PO

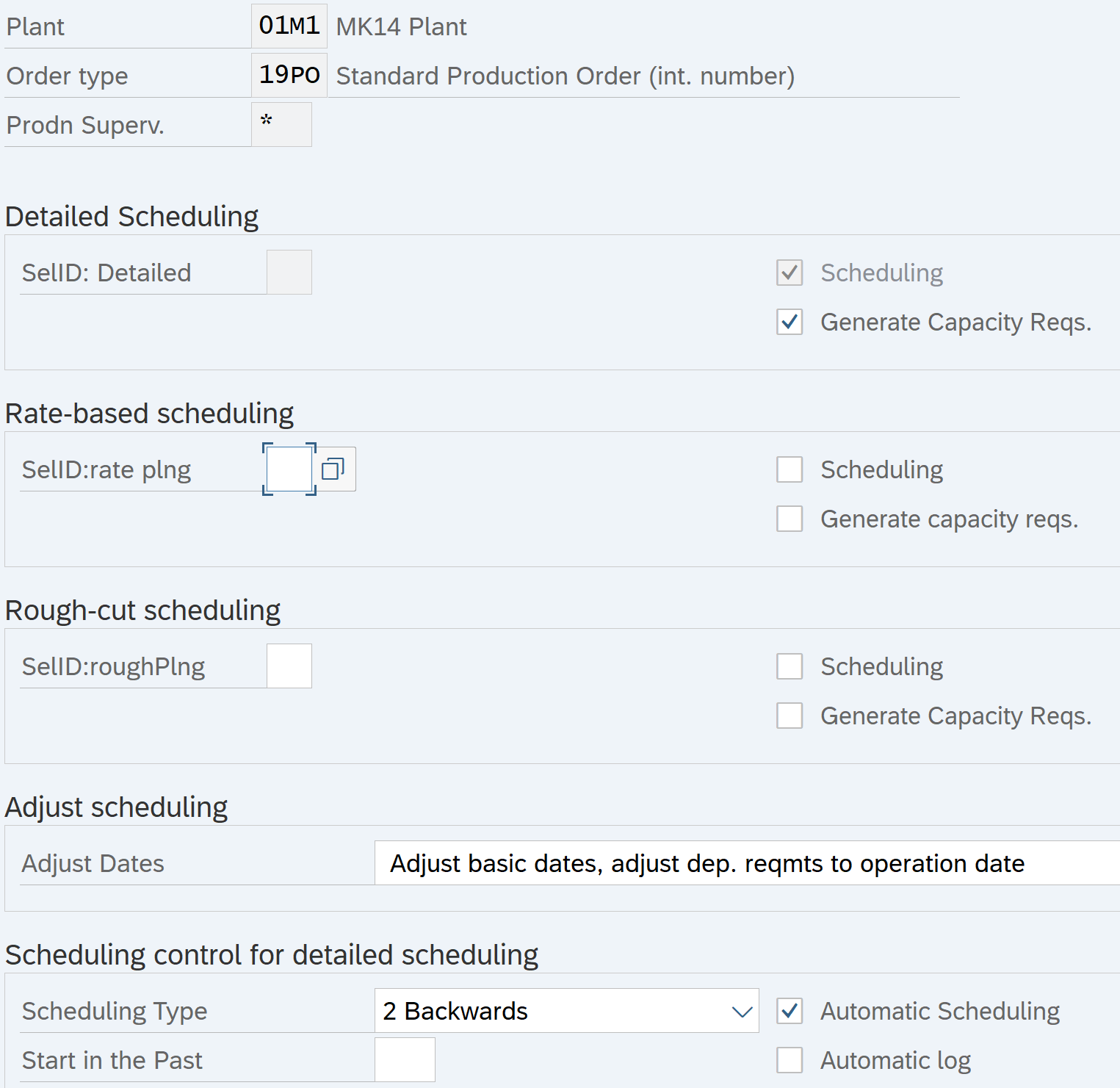

Define Scheduling Parameters for Production Order

Path: Production- Shop Floor control – operations – scheduling -define scheduling parameters for production orders

Tcode: OPU3

Copy Plant 1000 and Order type PP01 as Plant 01M1 and Order type 19PO

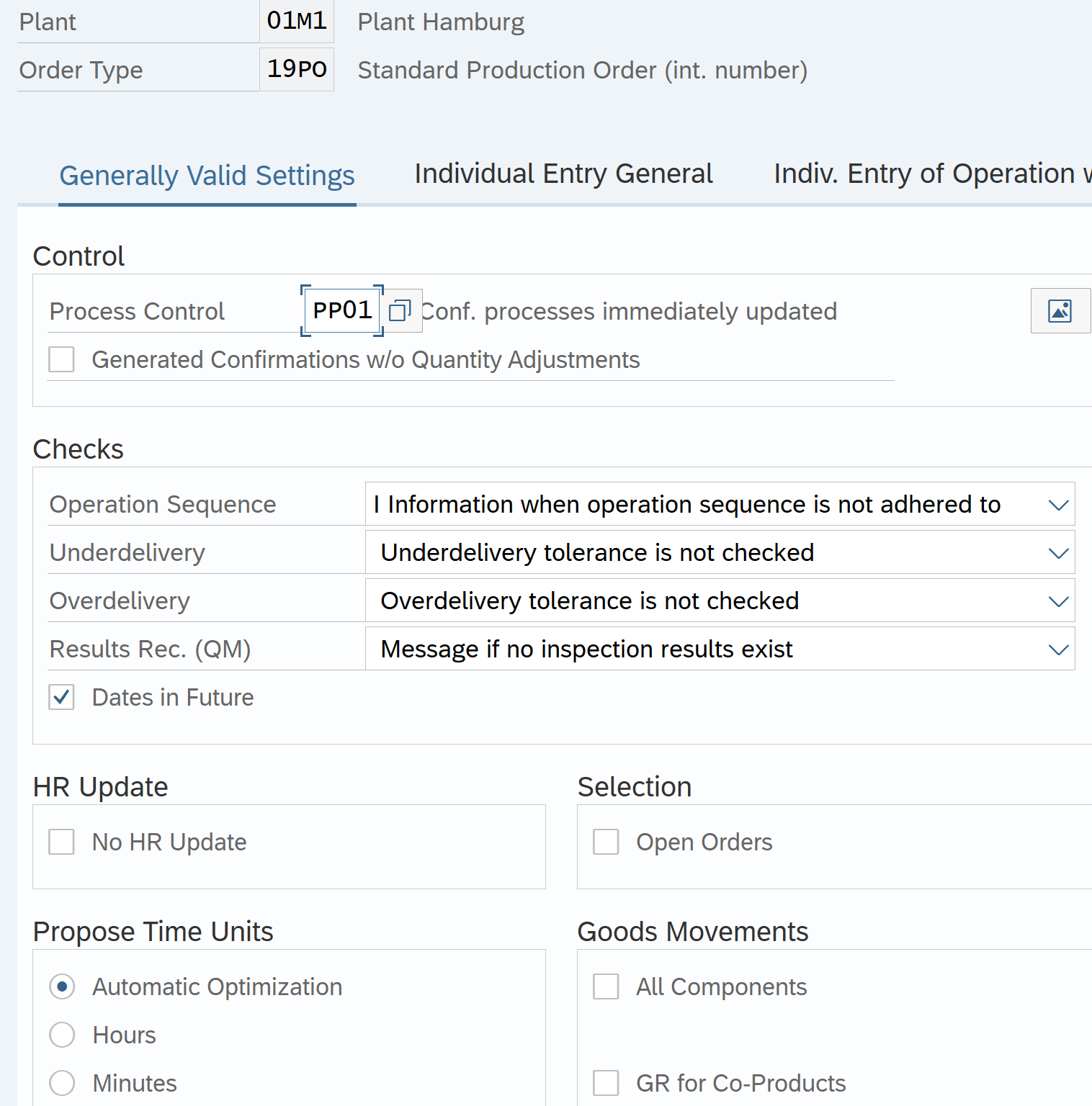

Define Confirmation Parameters

Path: Production- Shop Floor control – operations – confirmation – define confirmation parameters

Tcode: OPK4

Copy Plant 1000 and Order type PP01 as Plant 01M1 and Order type 19PO

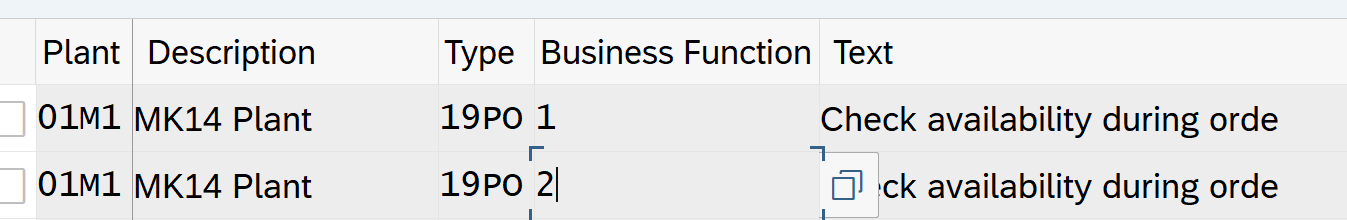

Define Checking control

Path: Production- Shop Floor control – operations – availability check – define checking control

Tcode: OPJK

Copy Plant 1000 and Order type PP01 as Plant 01M1 and Order type 19PO for business functions 1 and 2

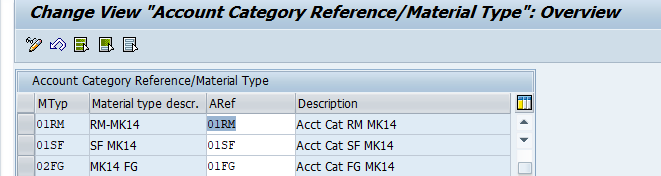

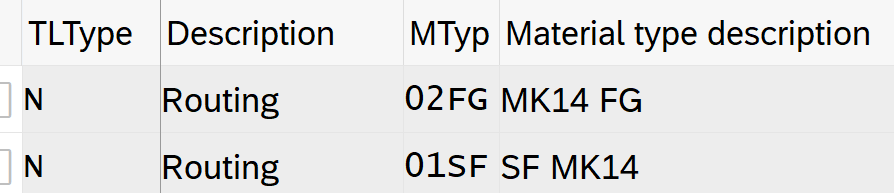

Define Material Type assignment

Path: Production – Basic Data – Routing – General Data – Define Material Type assignment

Tcode: OP50

Material Type 02FG and 01SF define in FI-MM

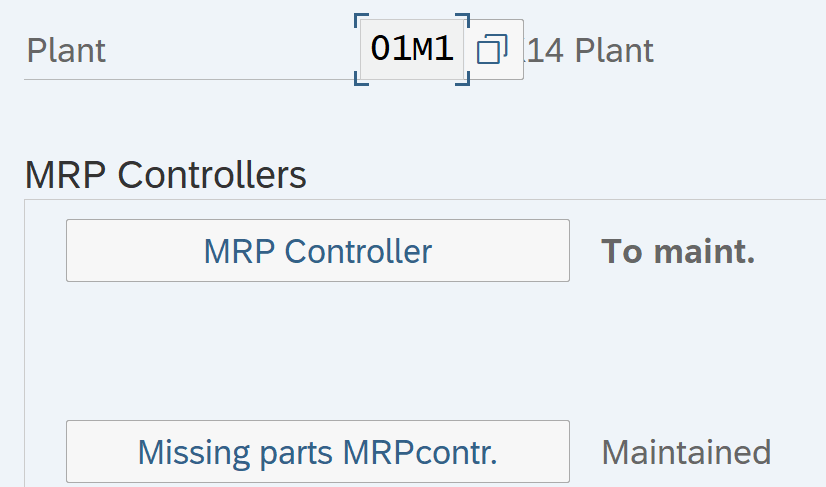

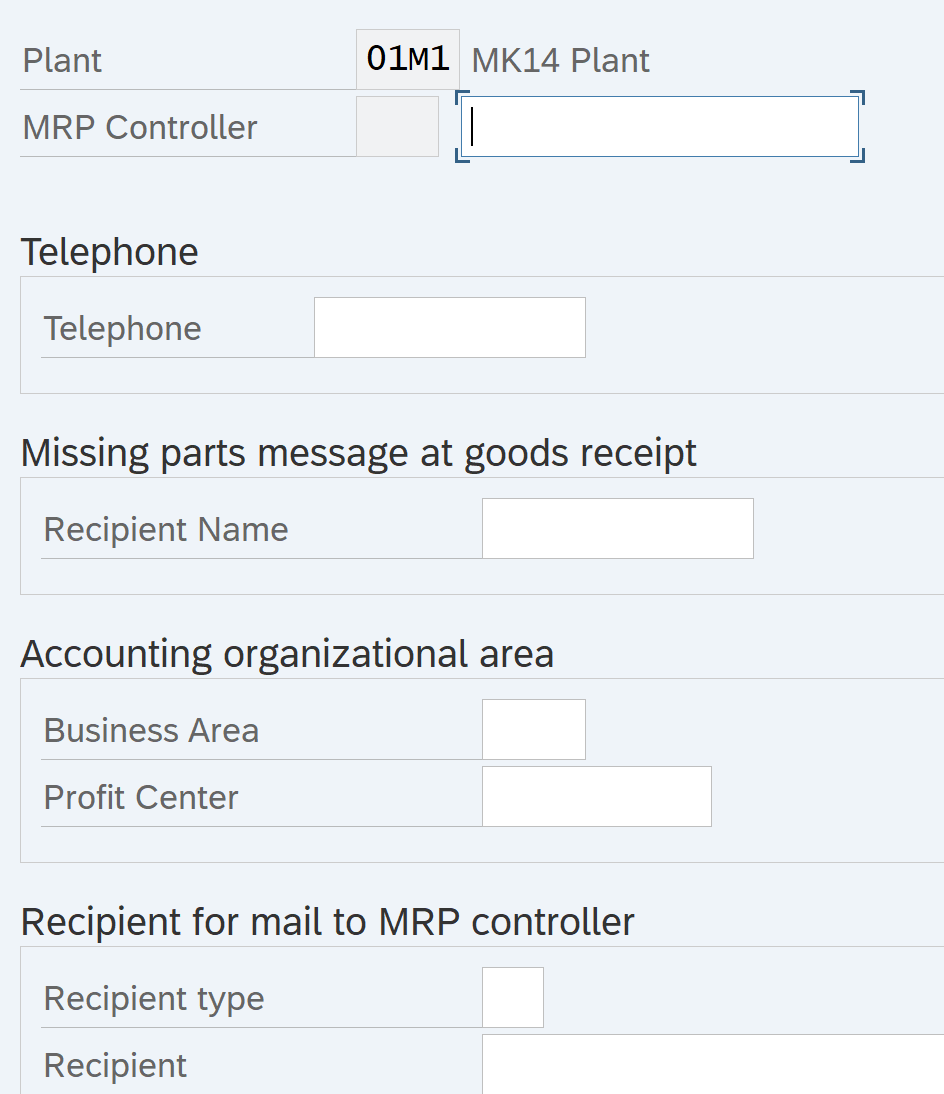

Maintain Overall Plant Parameters

Path: Production – MRP – Plant Parameters – carry out overall maintenance of plant parameters

Tcode: OPPQ

Copy Plant 1000 to Plant 01M1

Click on Maintain – Enter plant 01M1 – Click on MRP Controllers

Click on MRP controller – New entries – Enter Plant 01M1 and save

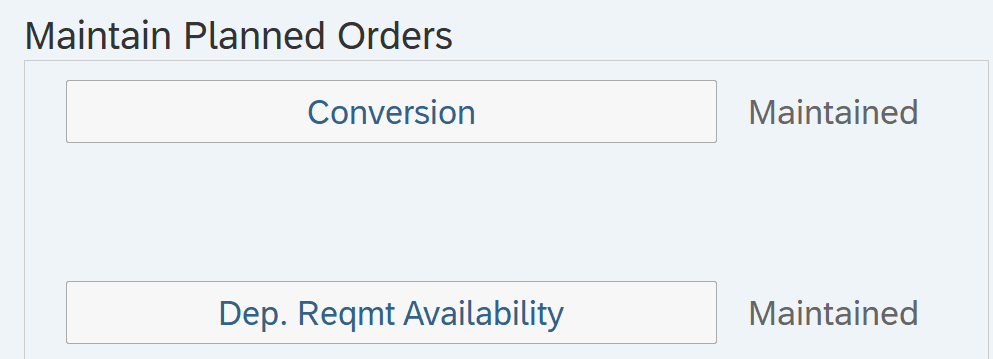

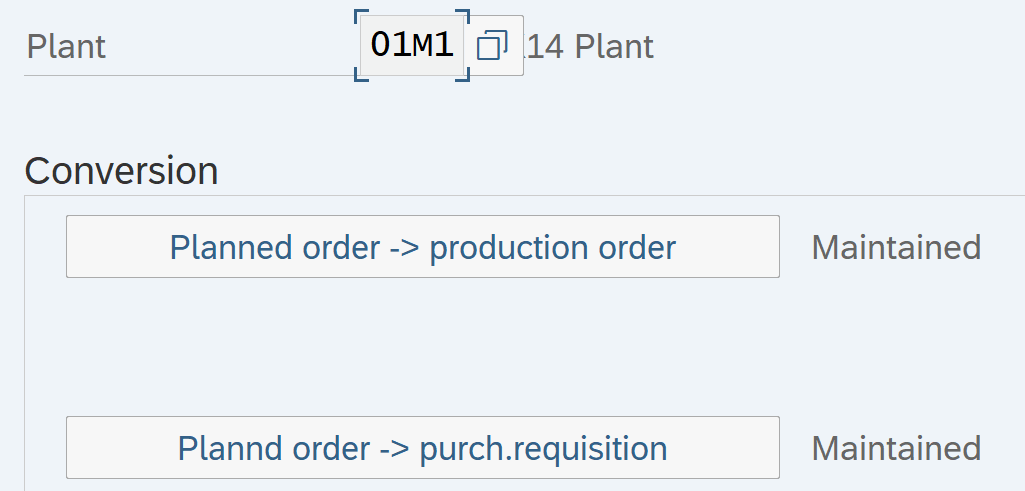

Click on Conversion under maintain planned orders

Click Planned Order and update Production Order to 19PO

Integration between CO and PP

Check Order Type

Path: Controlling – Product Cost Controlling – Cost Object Controlling – Product Cost by Order – Manufacturing Orders – Check Order Types

Tcode: KOT2

Update your order type 19PO as below

Update Settlement Profile

Update Object Class: Production

Residence Time: 6

SAP Product Costing Training-Advance

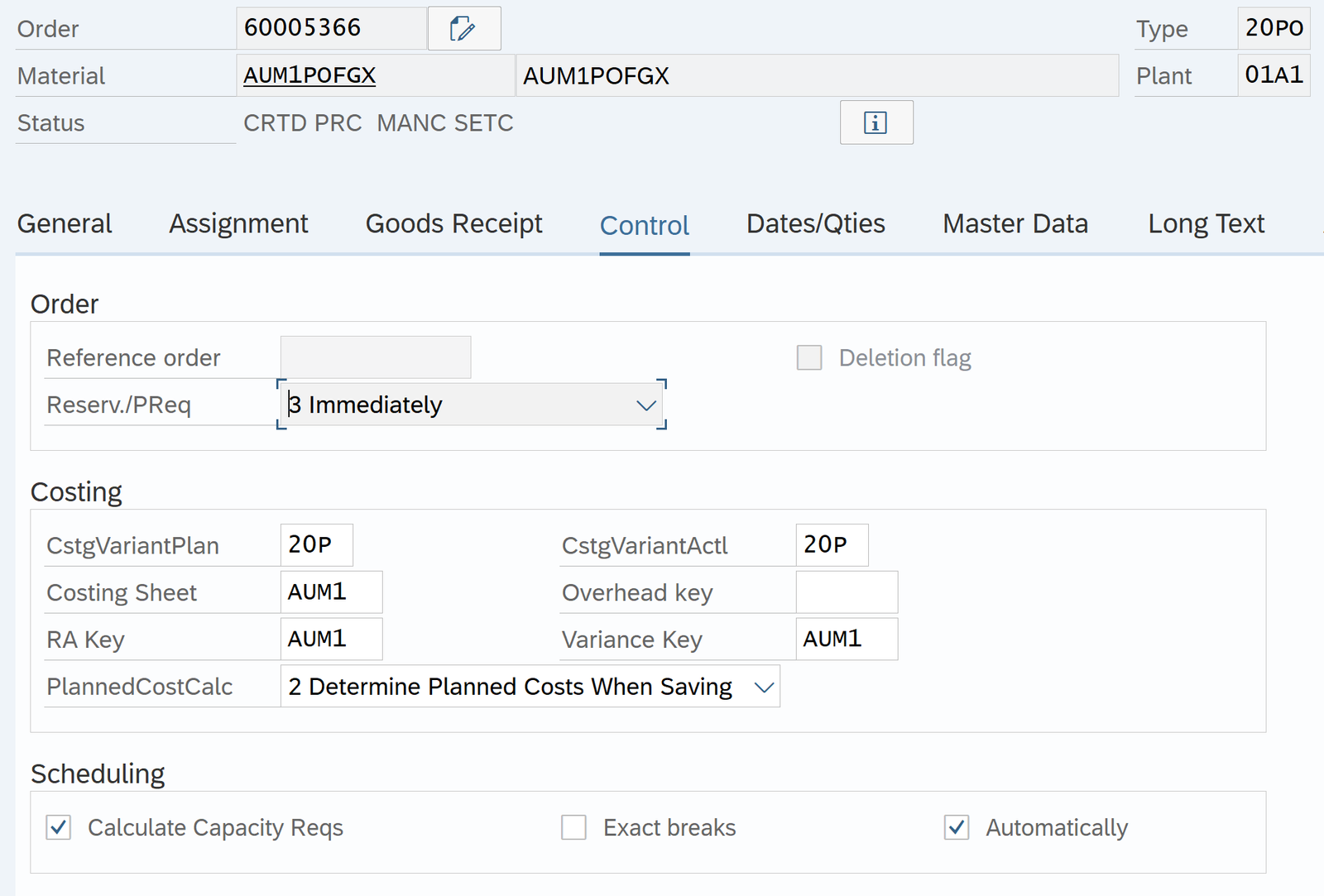

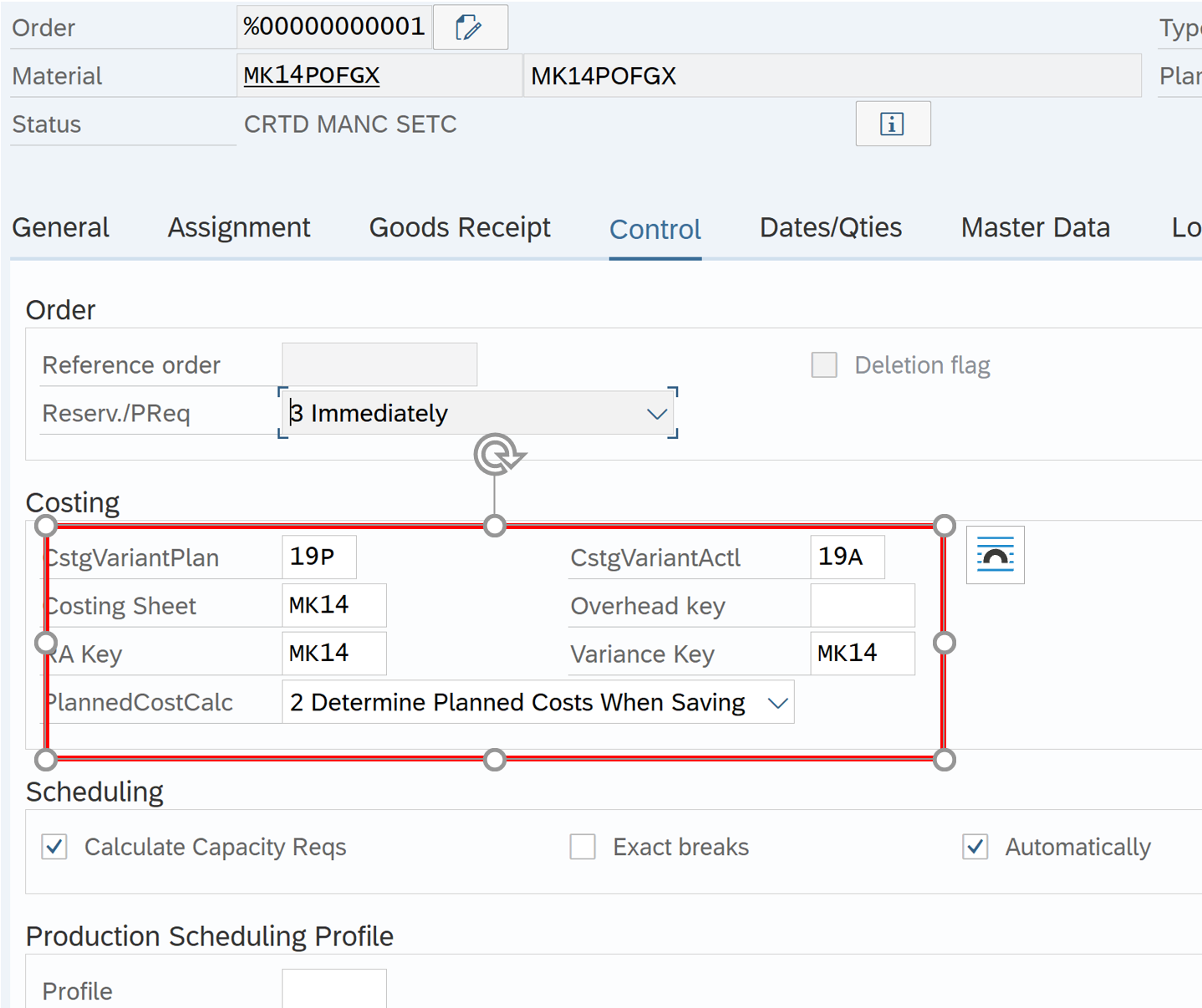

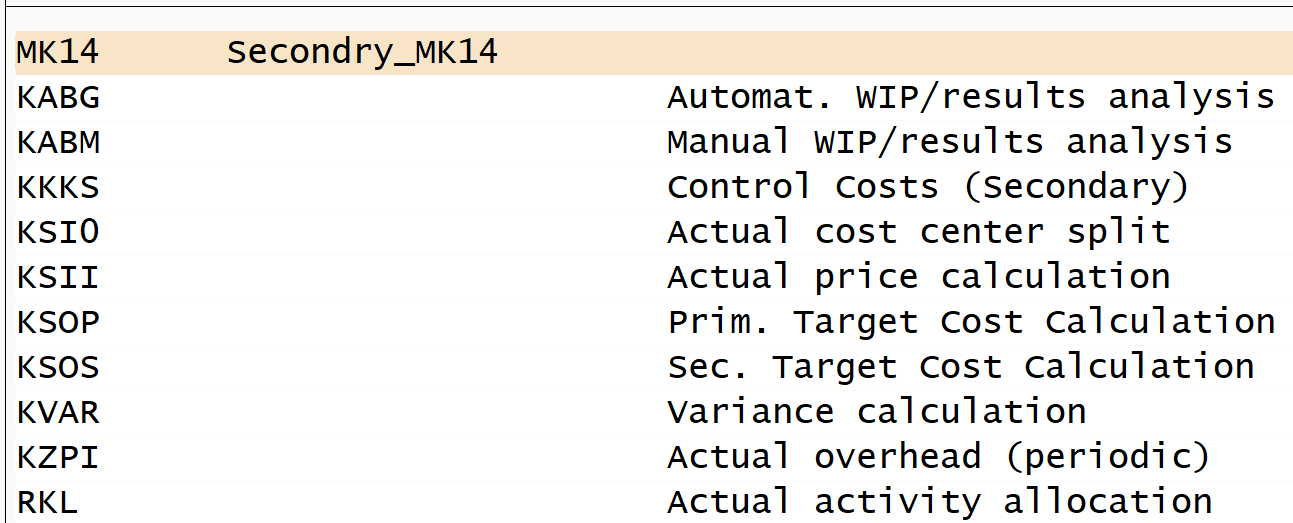

Define Cost Accounting relevant default values for order type

Path: Controlling – Product Cost Controlling – Cost Object Controlling – Product Cost by Order – Manufacturing Orders

Update as below:

RA Key: MK14

Costing Variant Plan: 19P

Costing Variant Actual: 19A

End User Steps

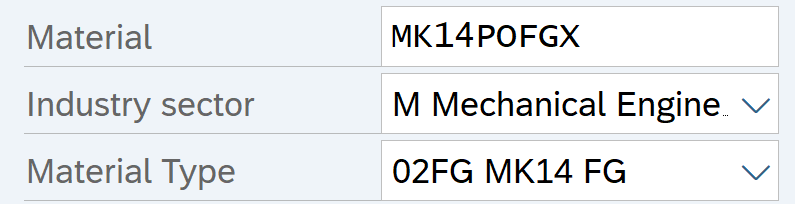

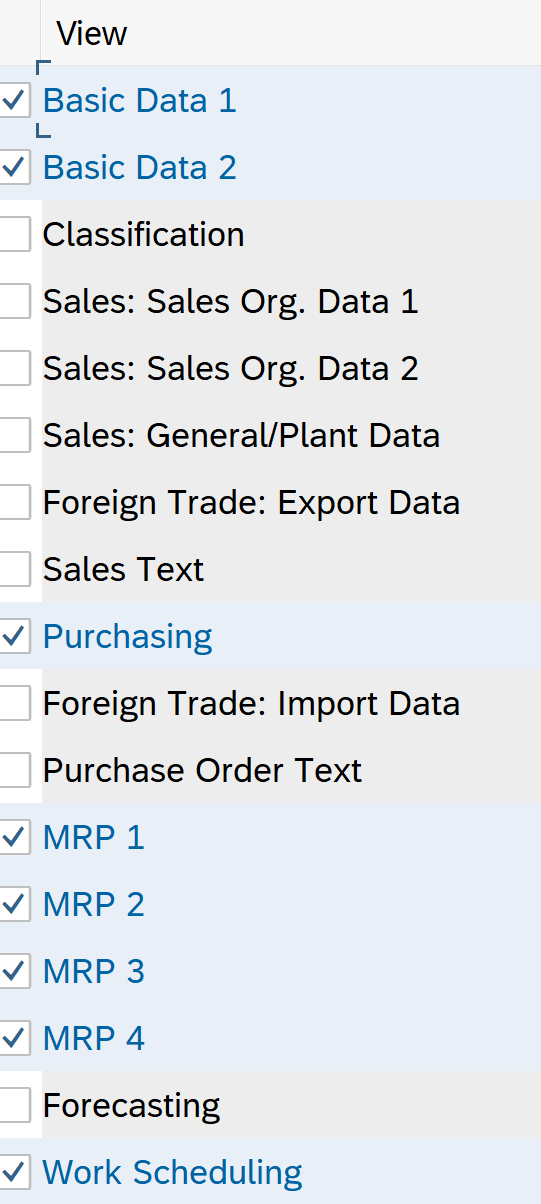

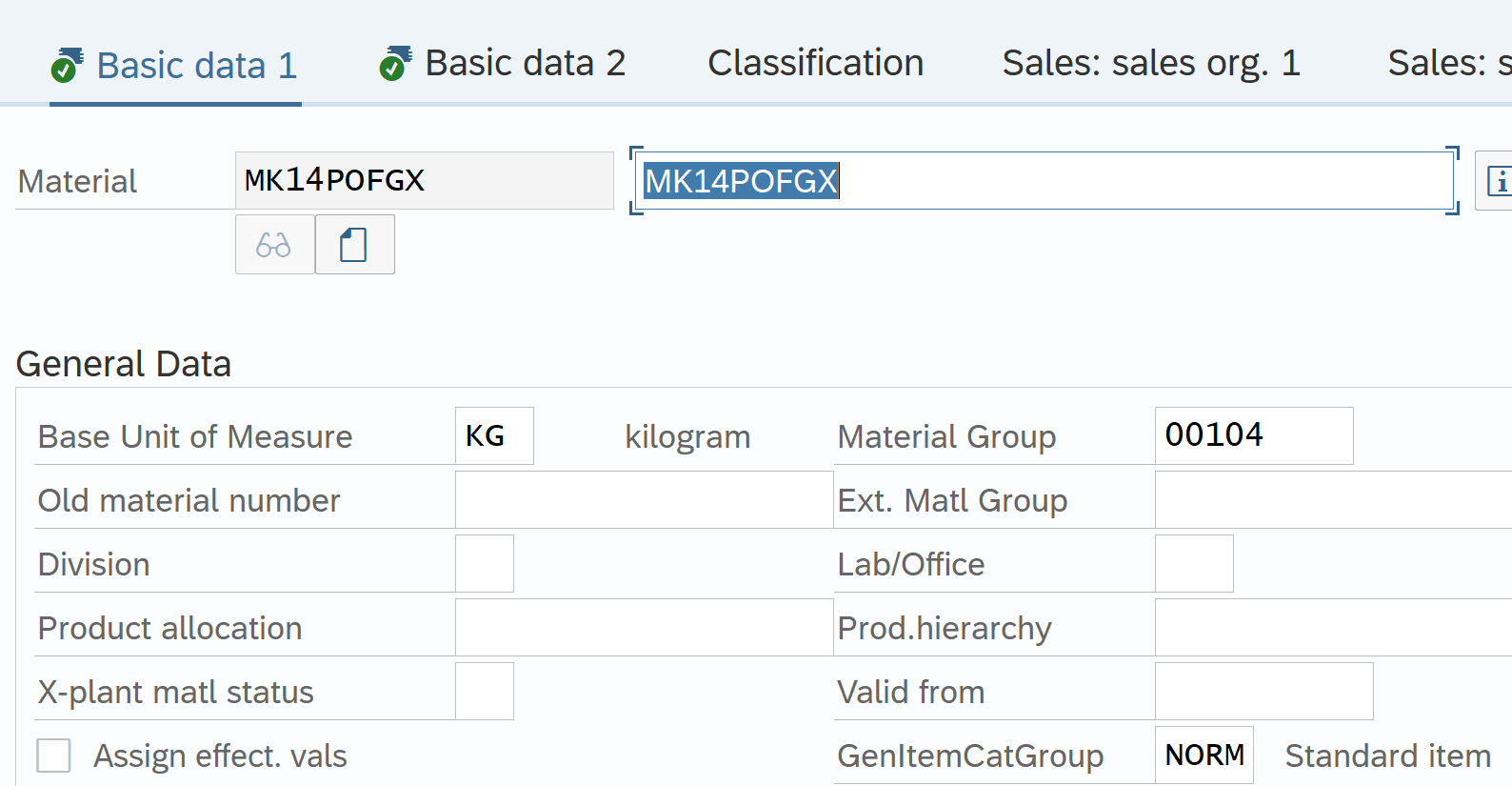

Create Finished Goods Material Master

Tcode: MM01

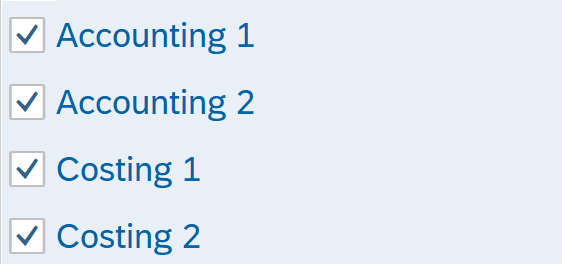

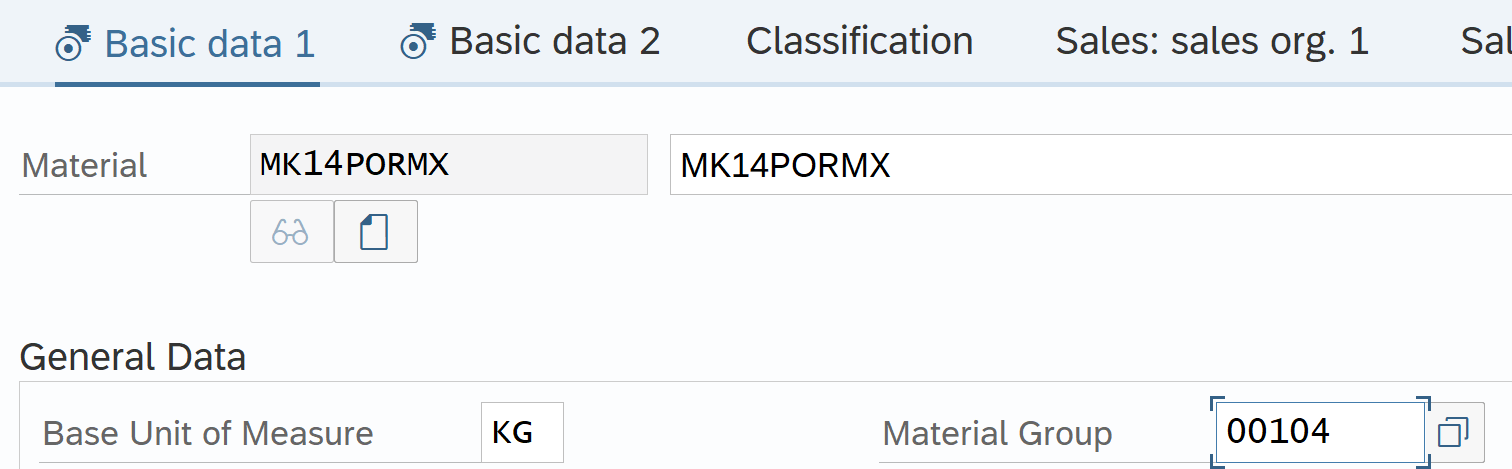

Basic Data 1 and 2 view

- Required for all material types

- Fields: Base Unit of Measure, Material Group, X-Plant Status, Prod Hierarchy

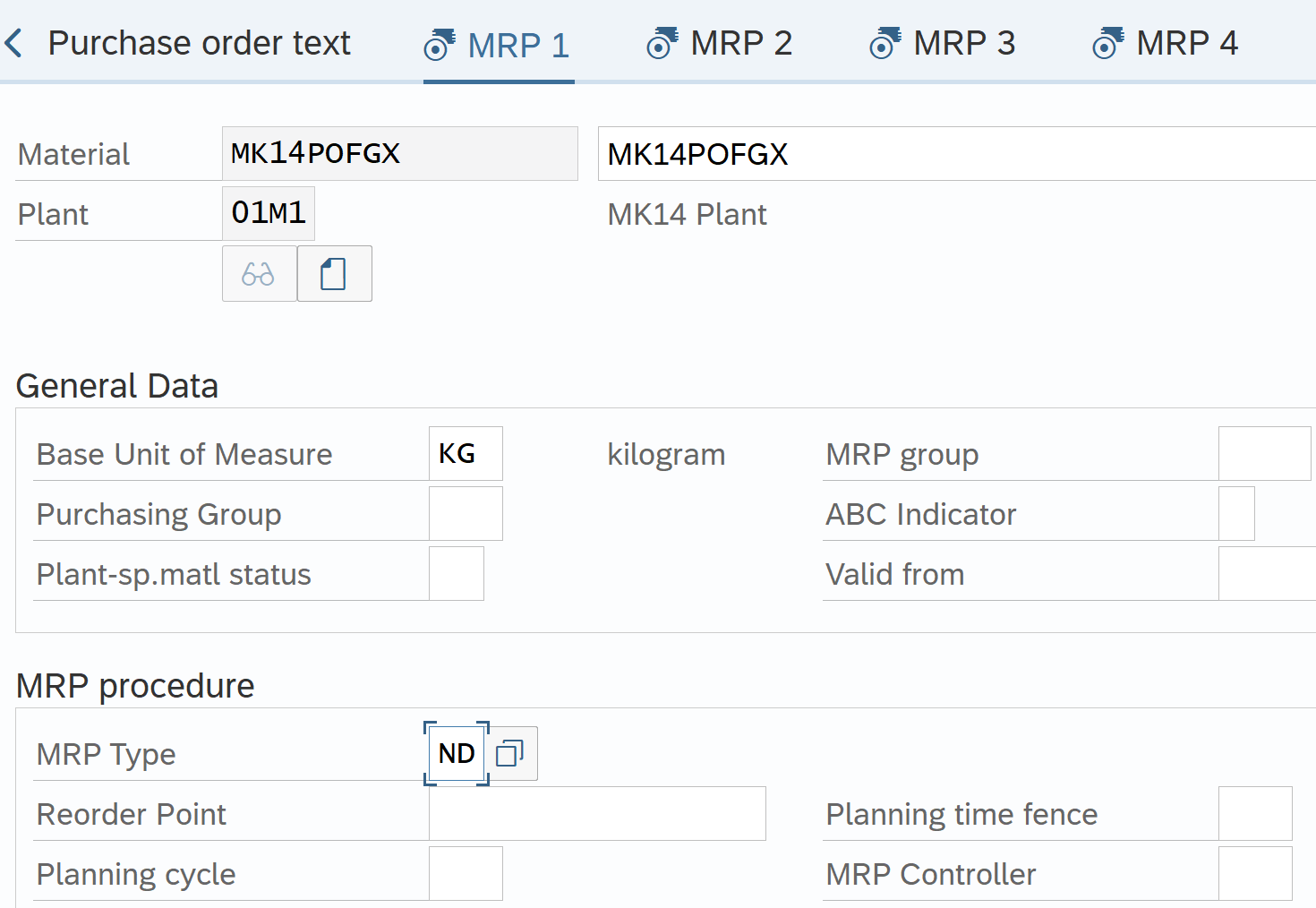

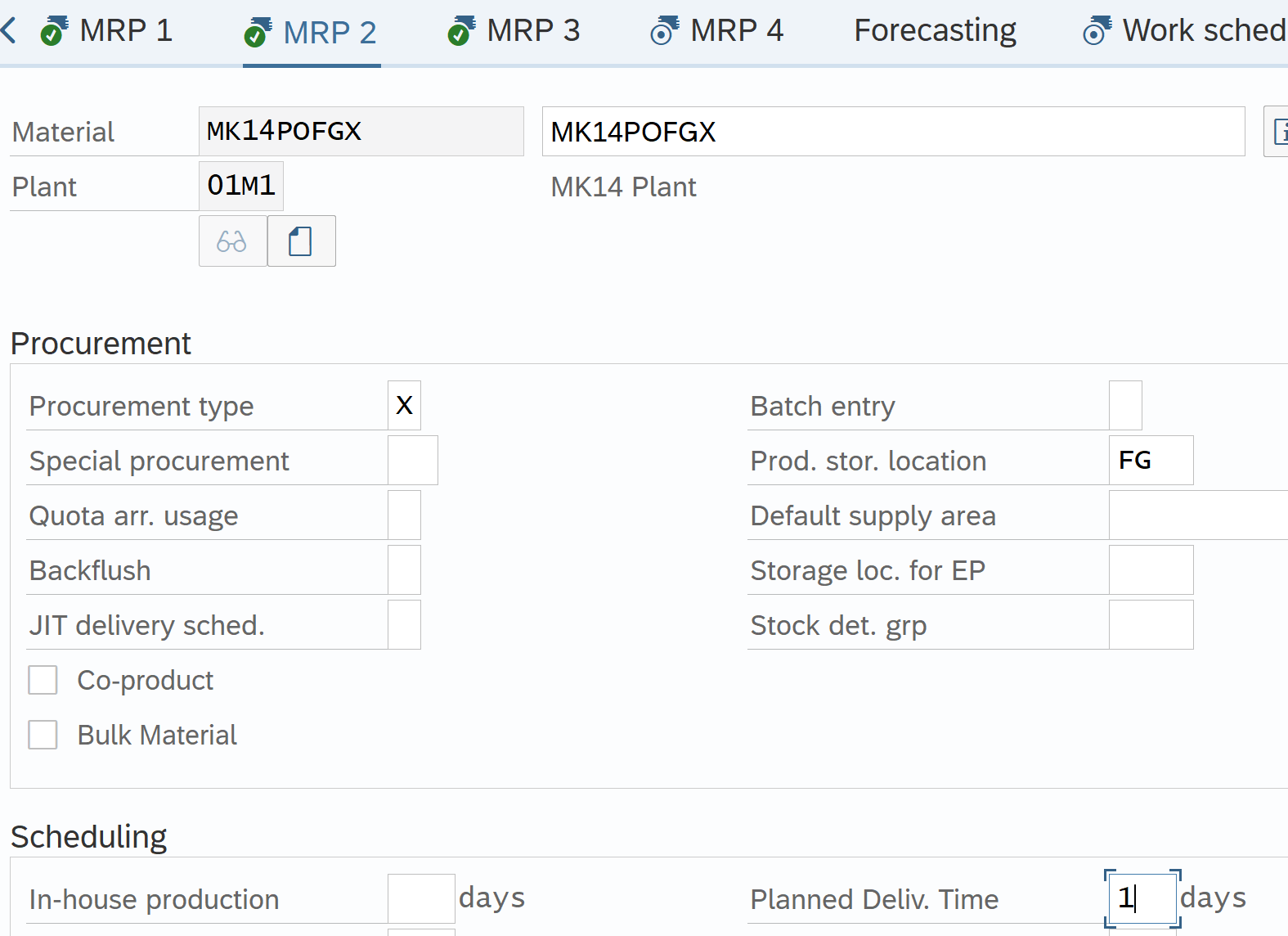

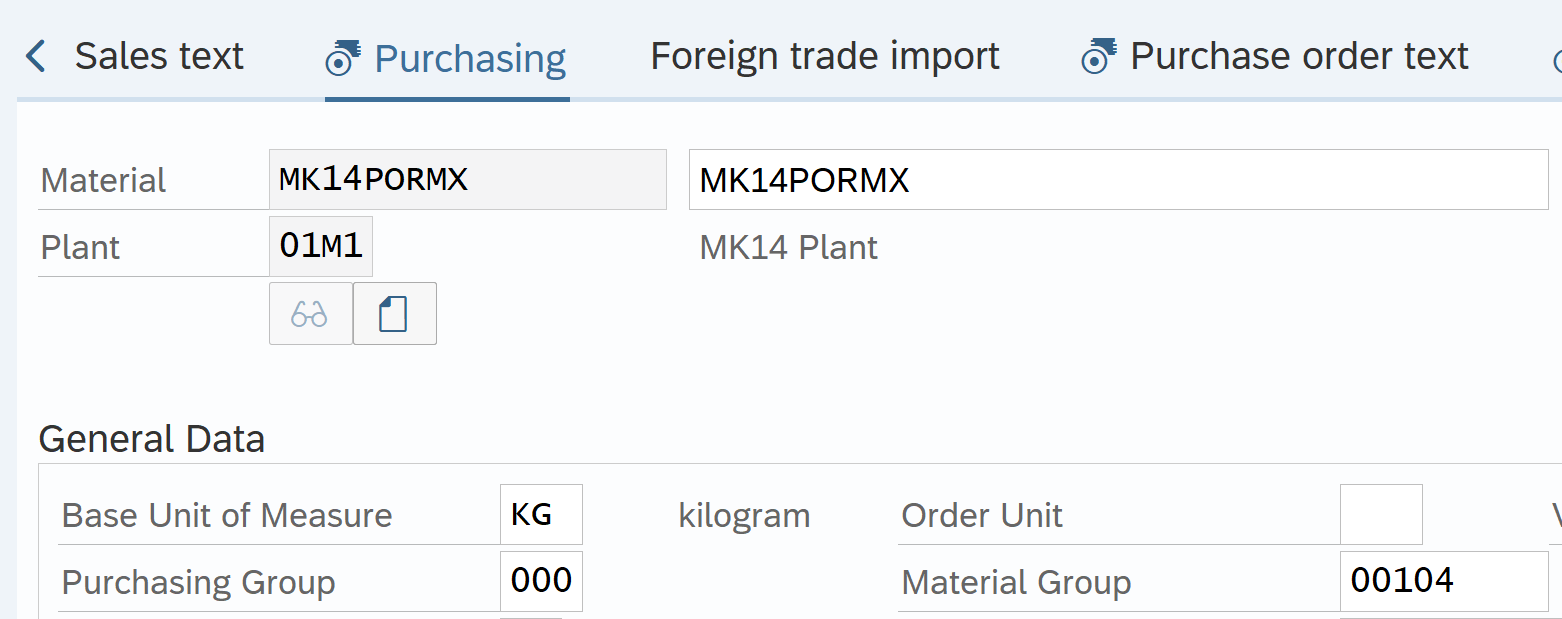

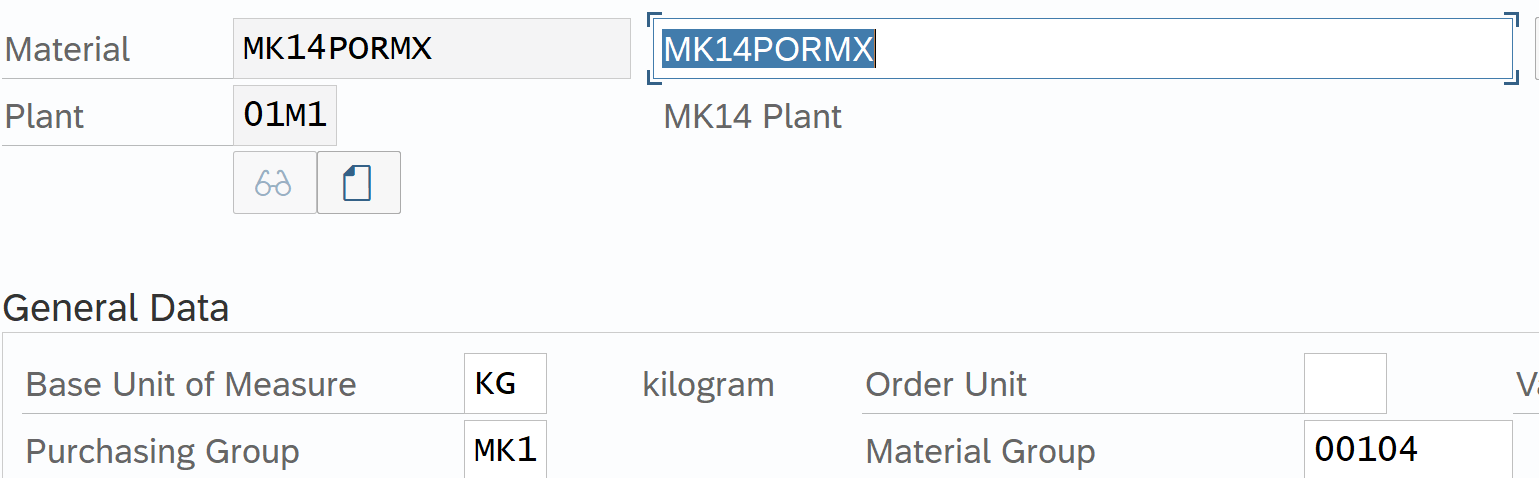

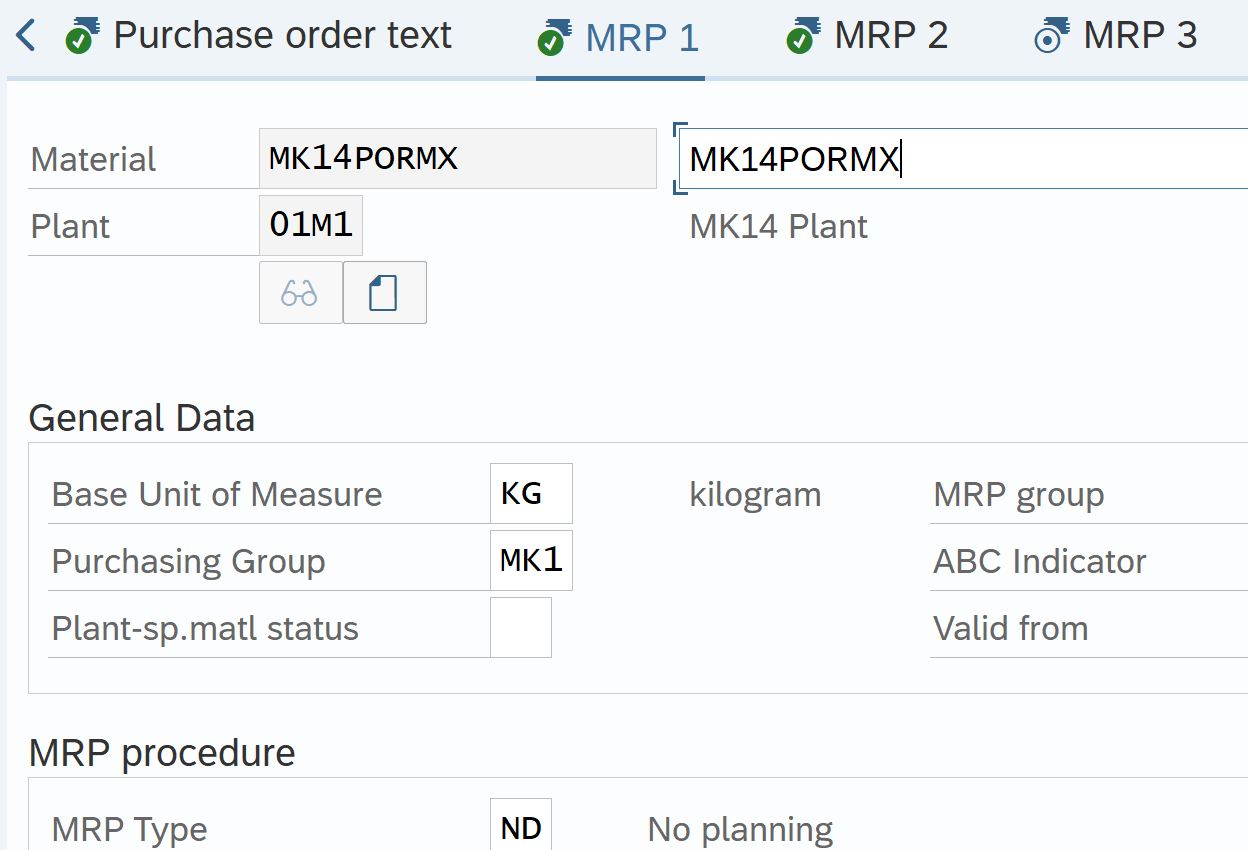

MRP 1 View (Material Requirement Planning)

- MRP Type: ND (No Planning)

- Procurement Type: X (Both Internal and External)

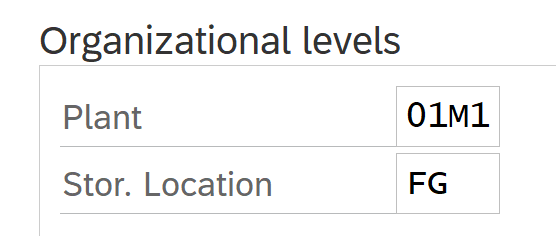

- Storage Location: FG

- Availability Check: KP (No Check)

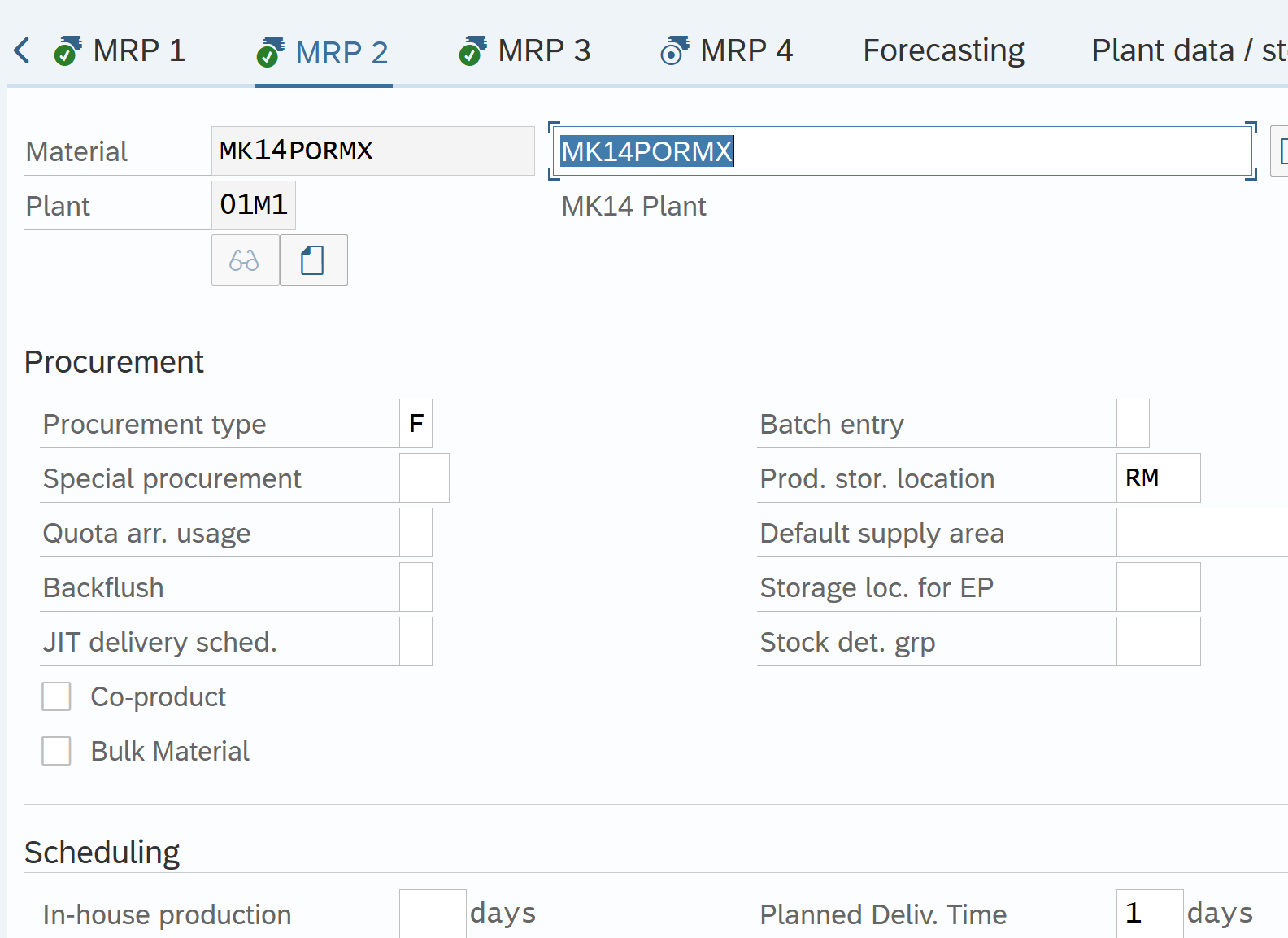

MRP 2 View

Back flush:

- Always Back flush

- Work Center decides

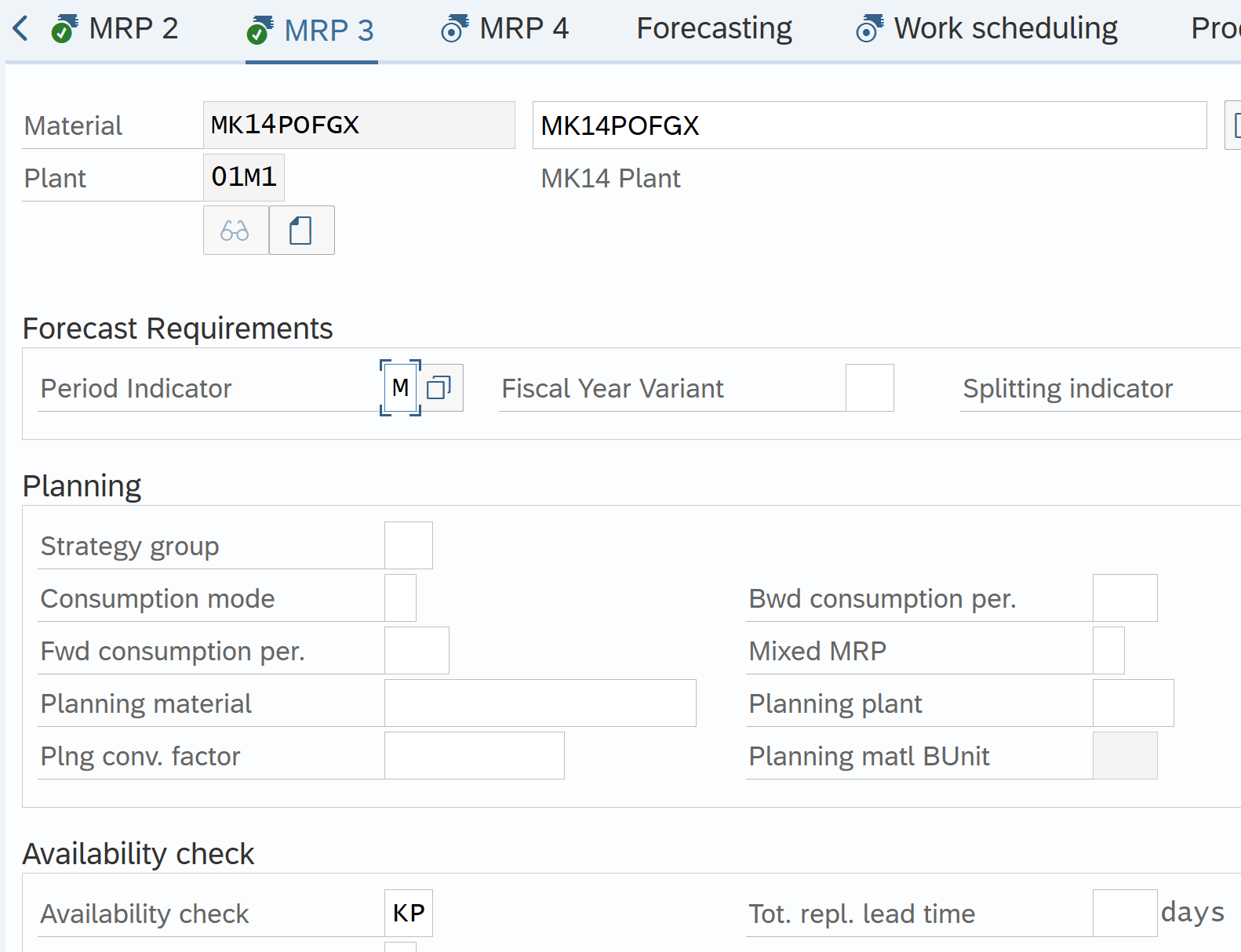

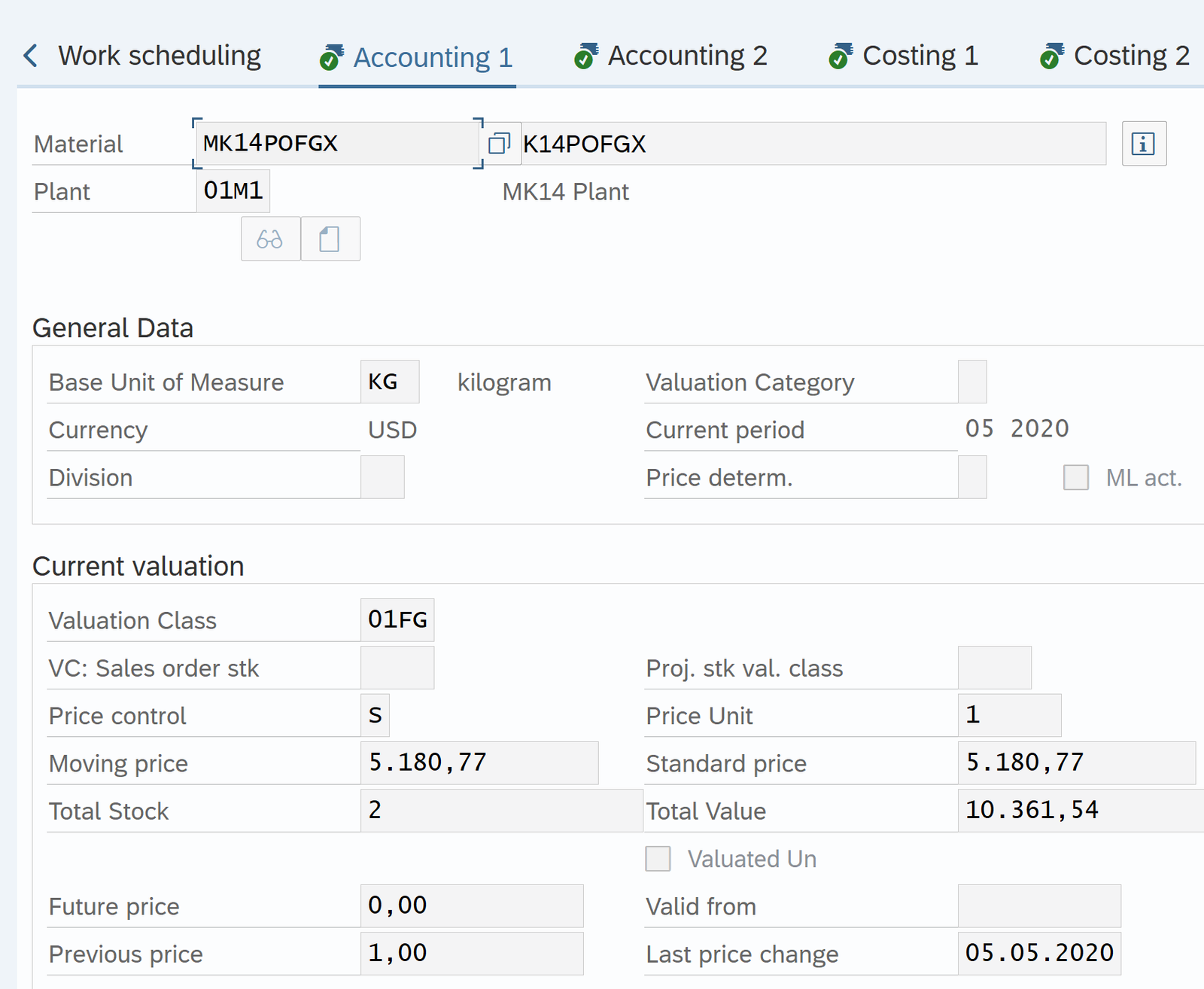

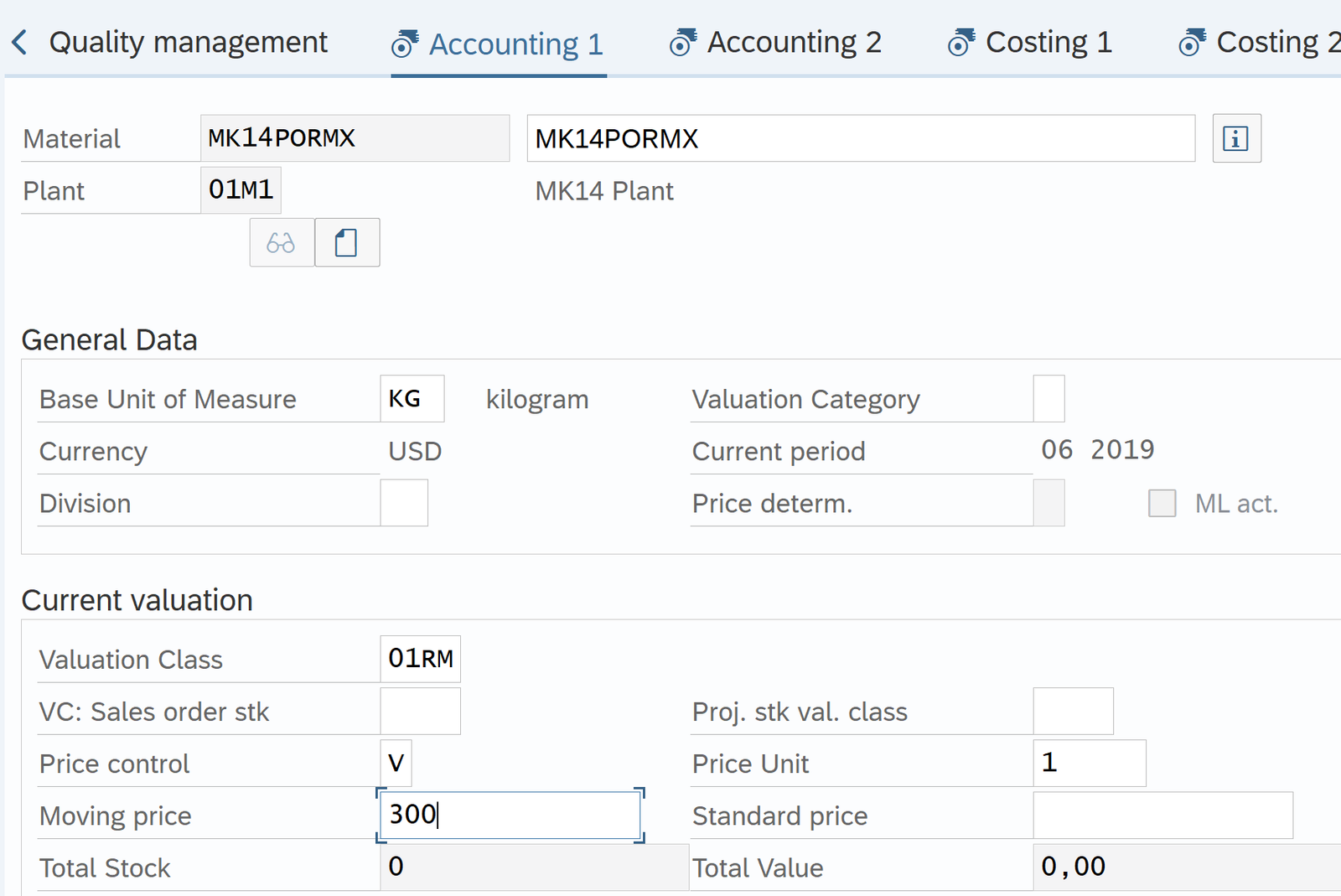

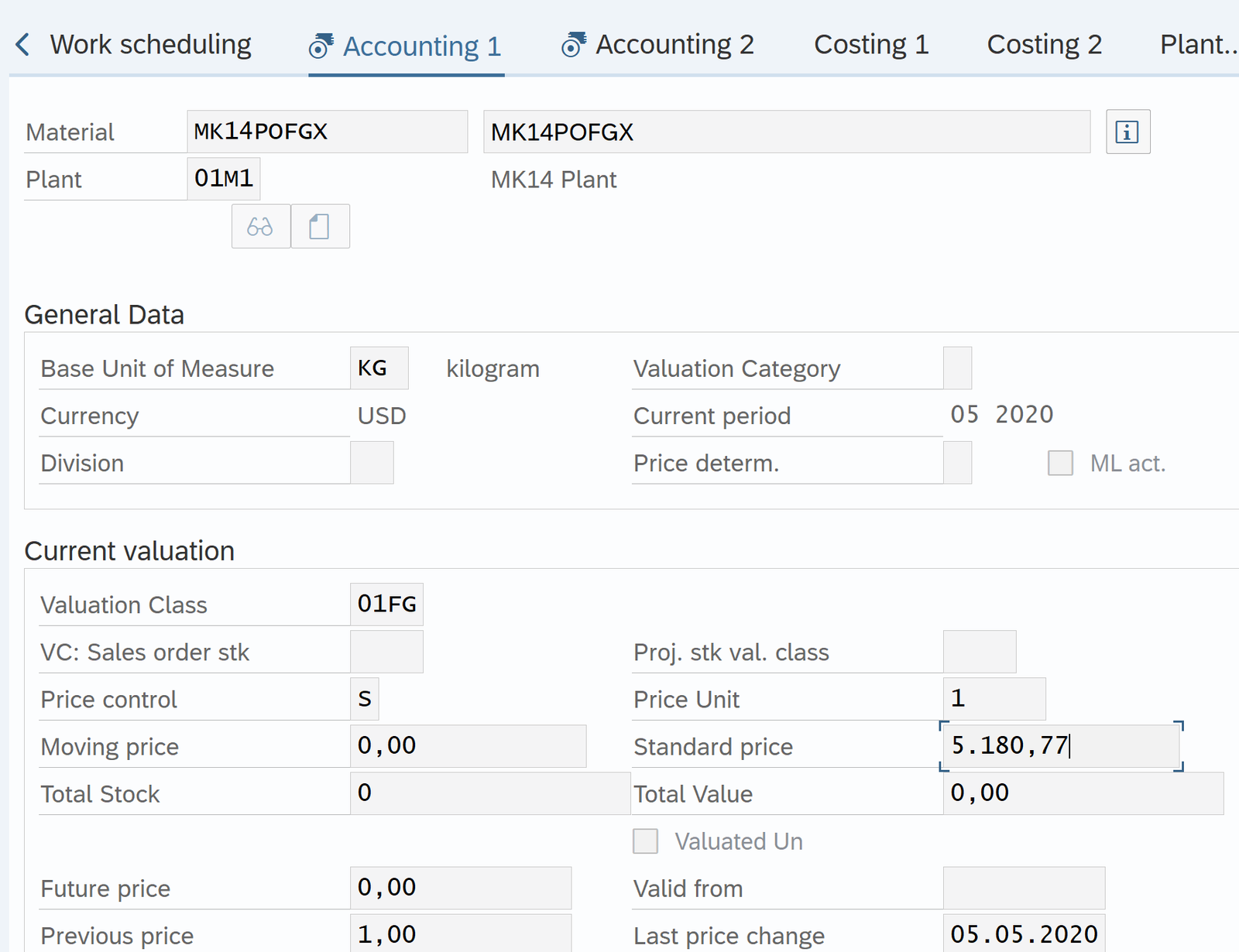

Accounting 1

- Valuation Class: Determine GL account posted

- Price Control

- S: Standard cost. Used for FG

- V: Moving average price. Used for Raw Material

- Price Unit: Cost per Unit ( Units specified here)

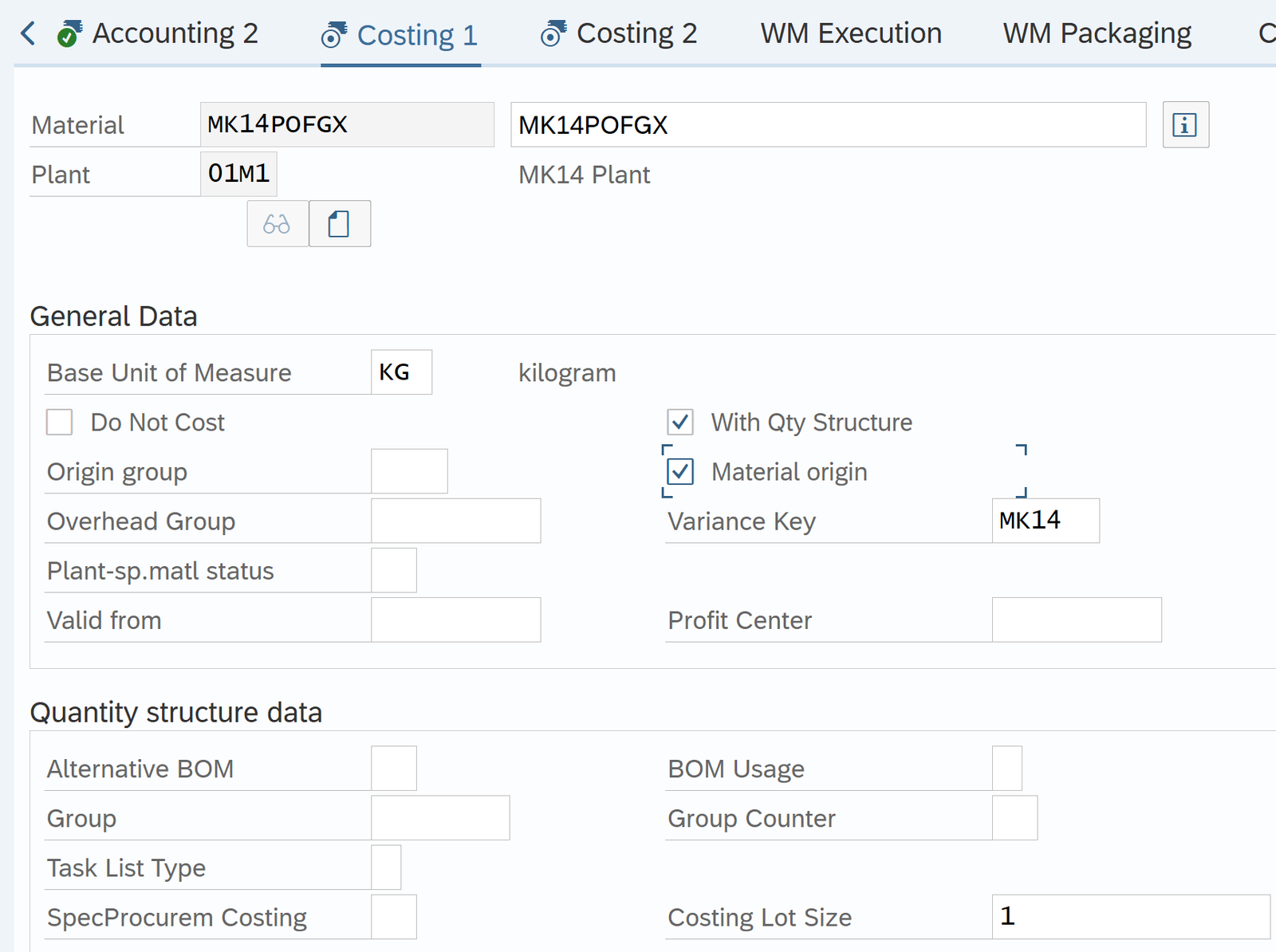

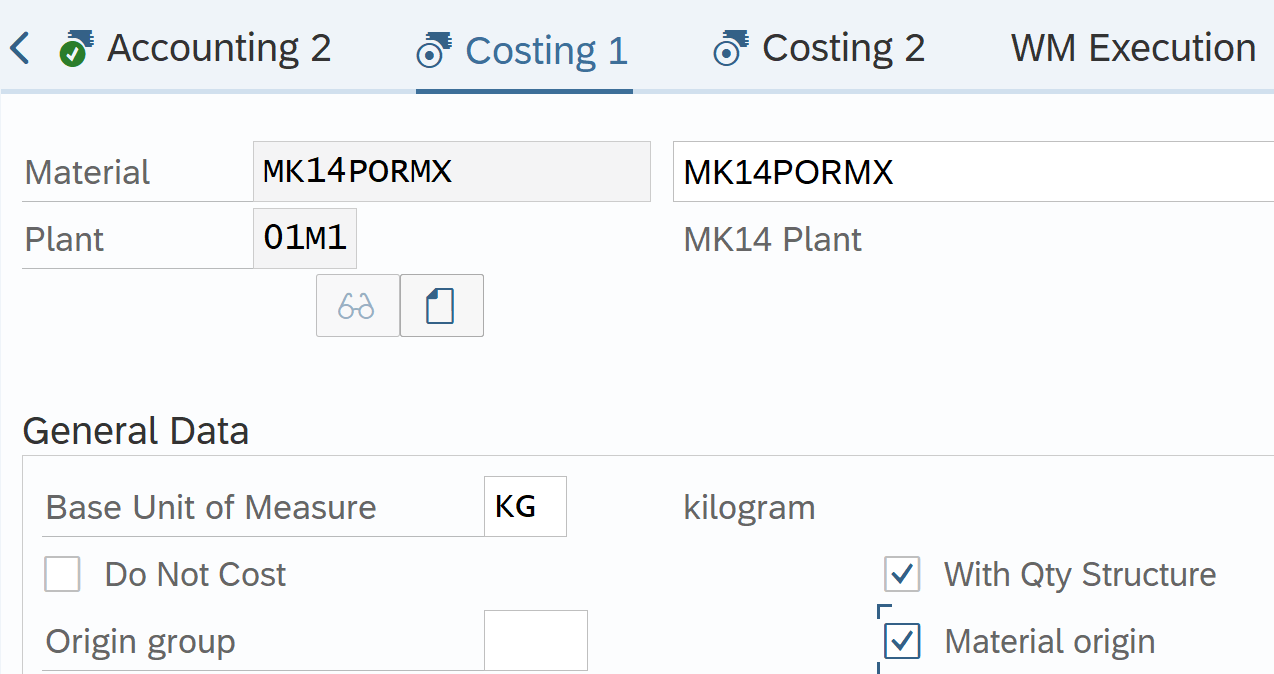

Costing 1

- With Qty Structure: Selected for material costed with BOM + Routing

- Material Origin: Select to display Material Number in controlling reports

- Variance Key: Specify the one created earlier.

- Costing Lot size

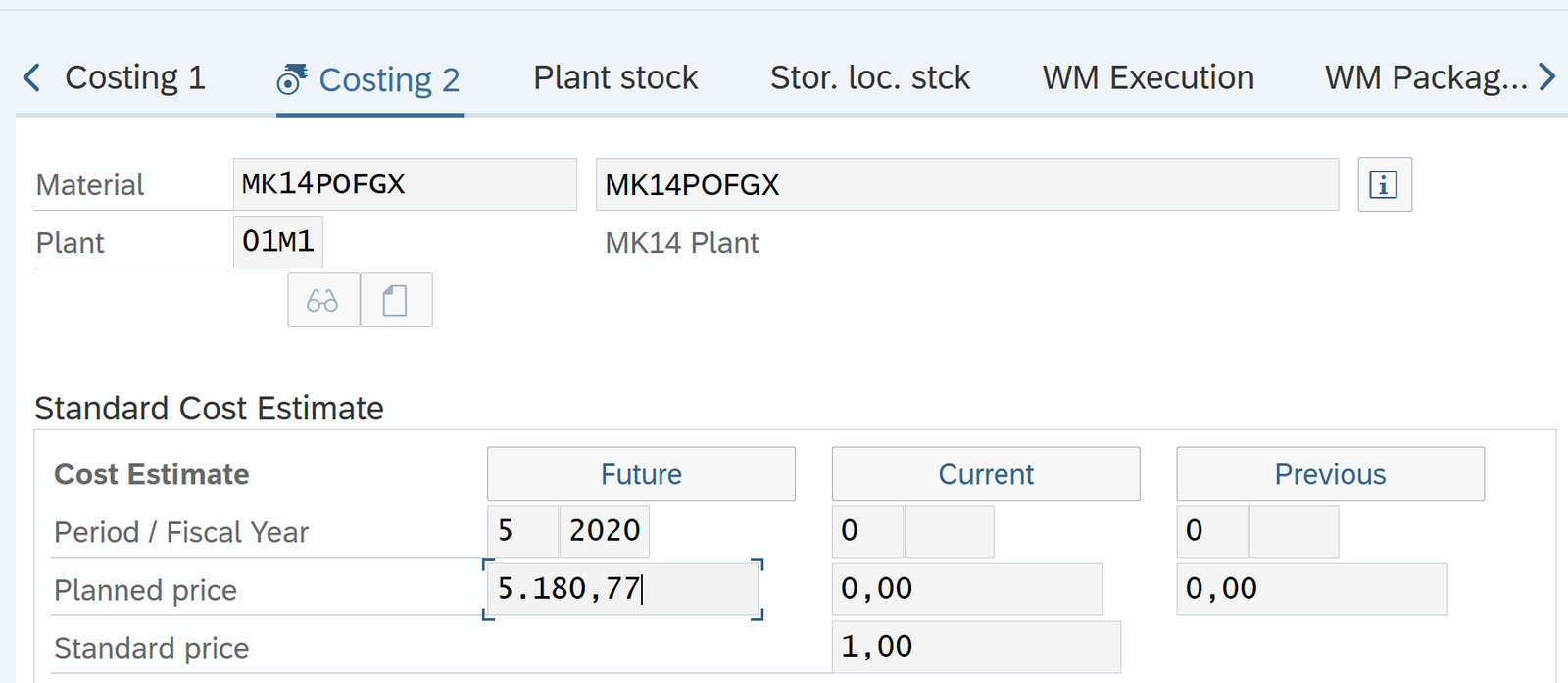

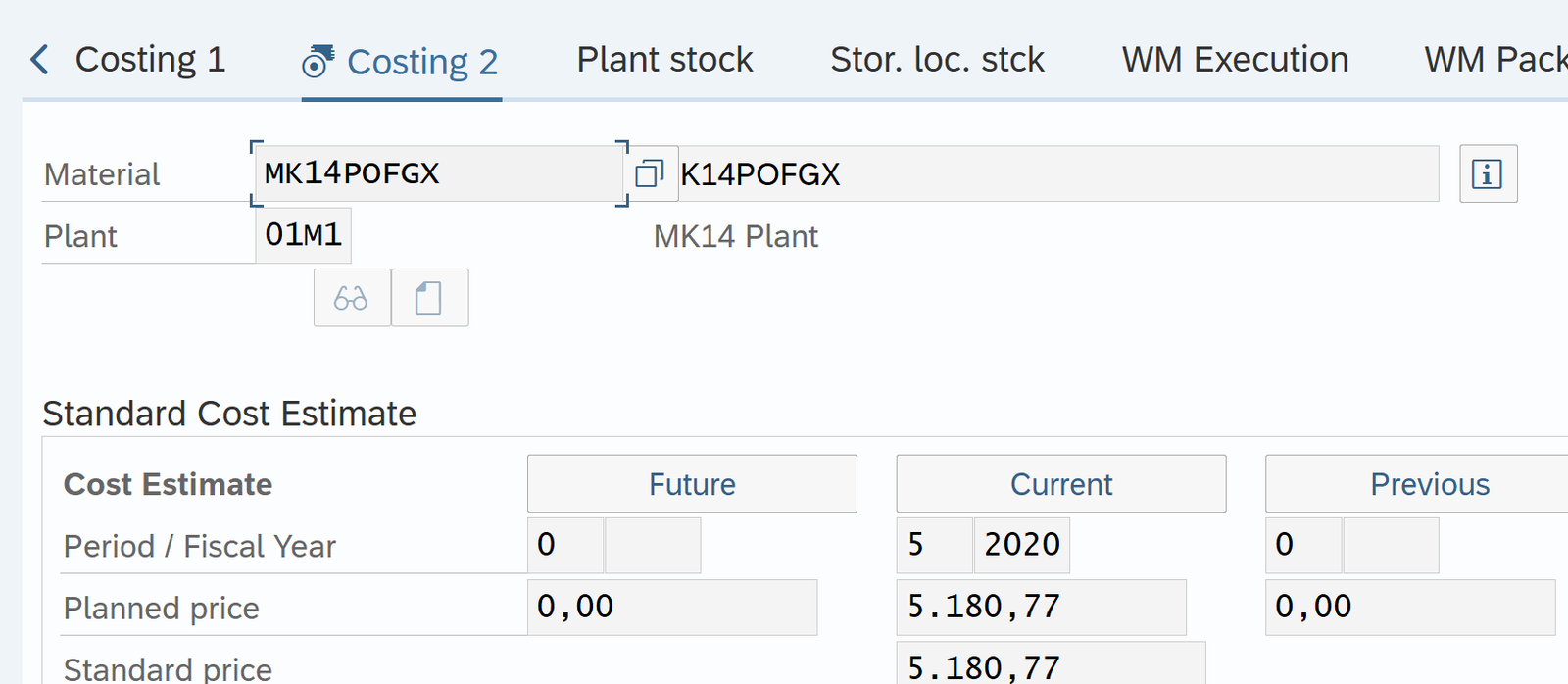

Costing 2

- Future Price: Current market price

- Current Price: Current Release Price

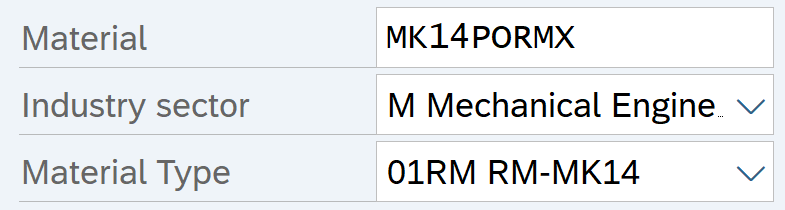

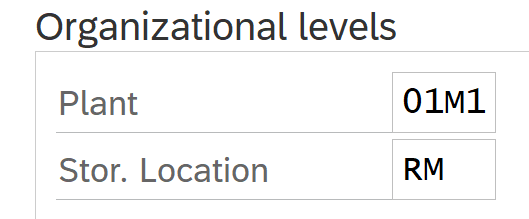

Tcode: MM01

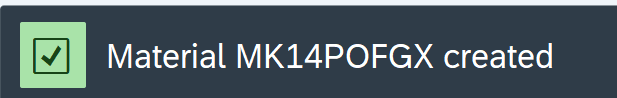

Material MK14PORMX created

Create MK14PORMY. Same as MK14PORMX

Material MK14PORMY created

| Finished Goods | Raw material |

| MK14POFGX | MK14PORMX |

| MK14PORMY |

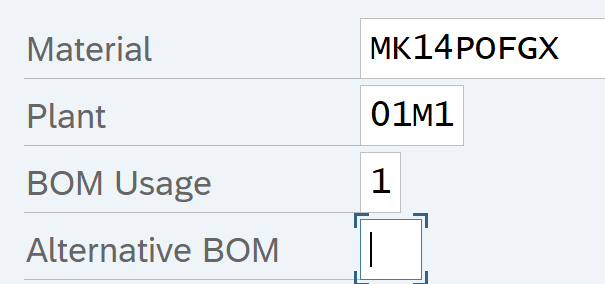

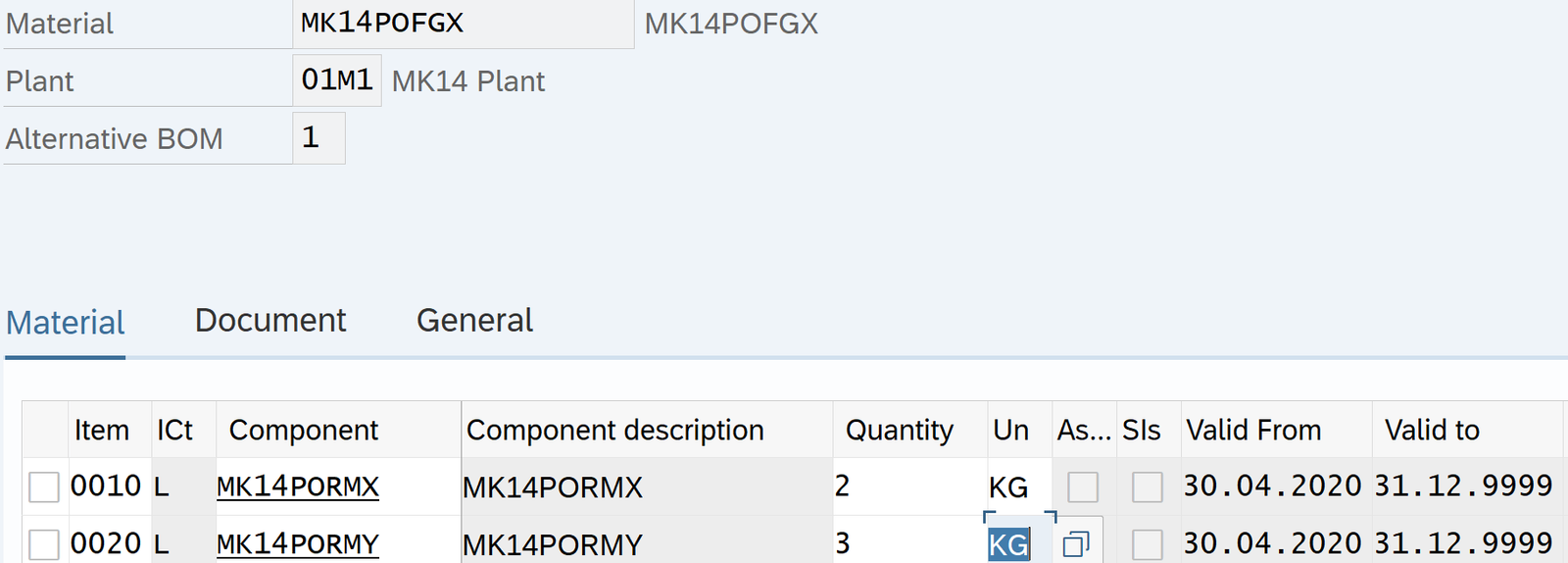

Create BOM

Tcode: CS01 / CS02 / CS03

Create Finished Goods BOM (Bill of Material)

Above BOM => need 2 kg and 3 Kg of Raw material X and Y to manufacture 1 Kg of FG

Routing

| Routing | Setup Activity | Machine Activity | Labor Activity | Work Center |

| Operation 10 | 1 | 2 | 3 | WC 1 |

| Operation 20 | 1 | 2 | WC 2 |

Routing is a list of Operations performed on Raw material to convert it into FG. These operations are performed at locations called work centers.

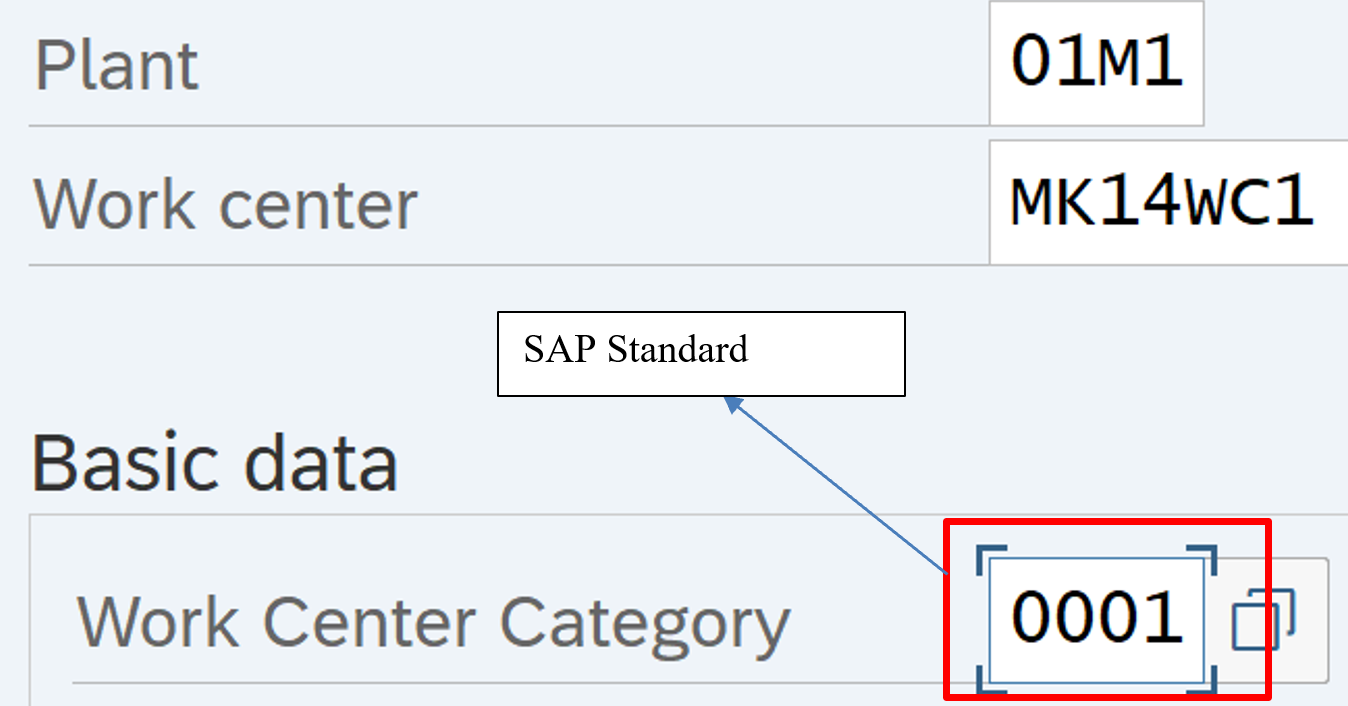

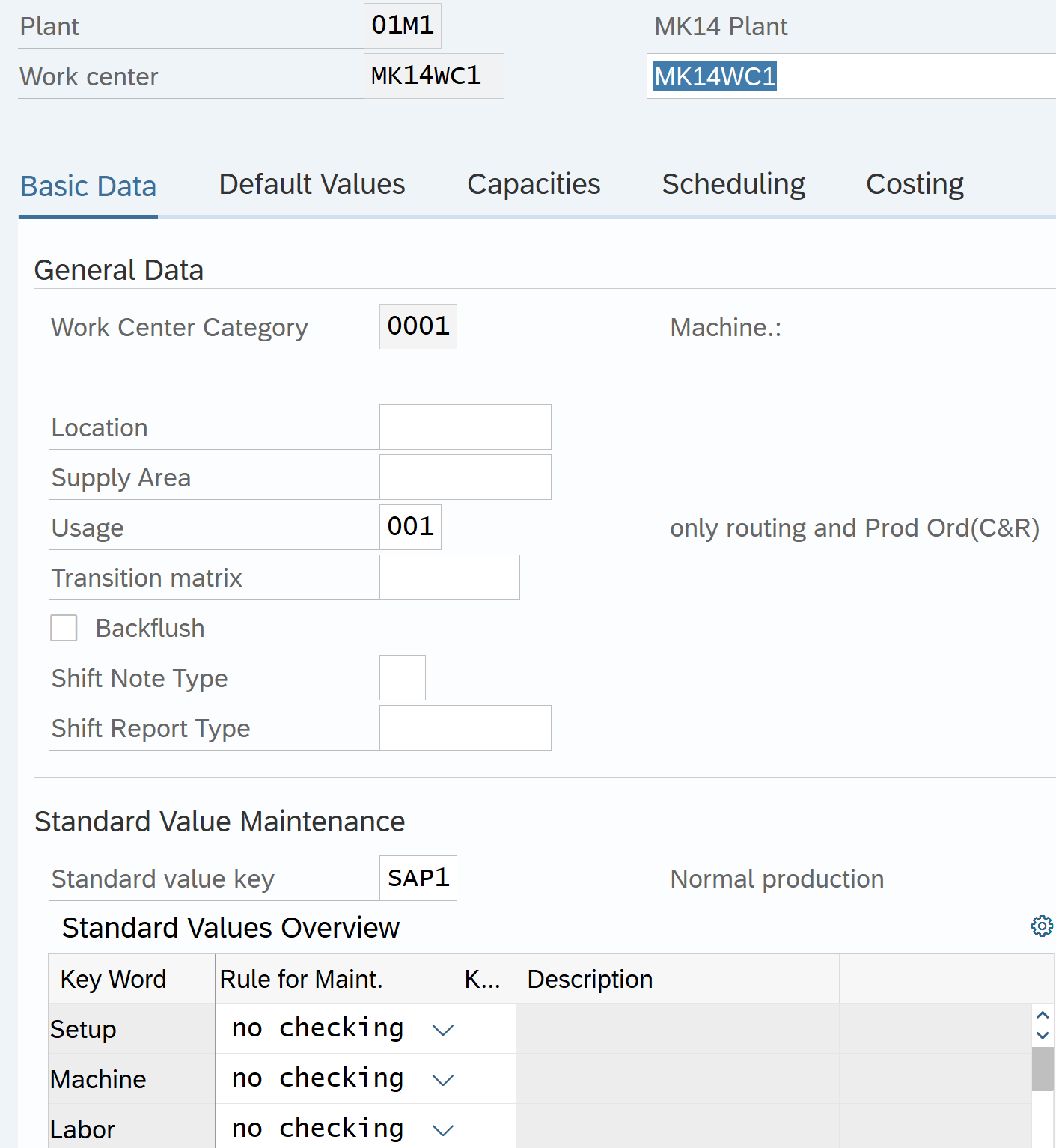

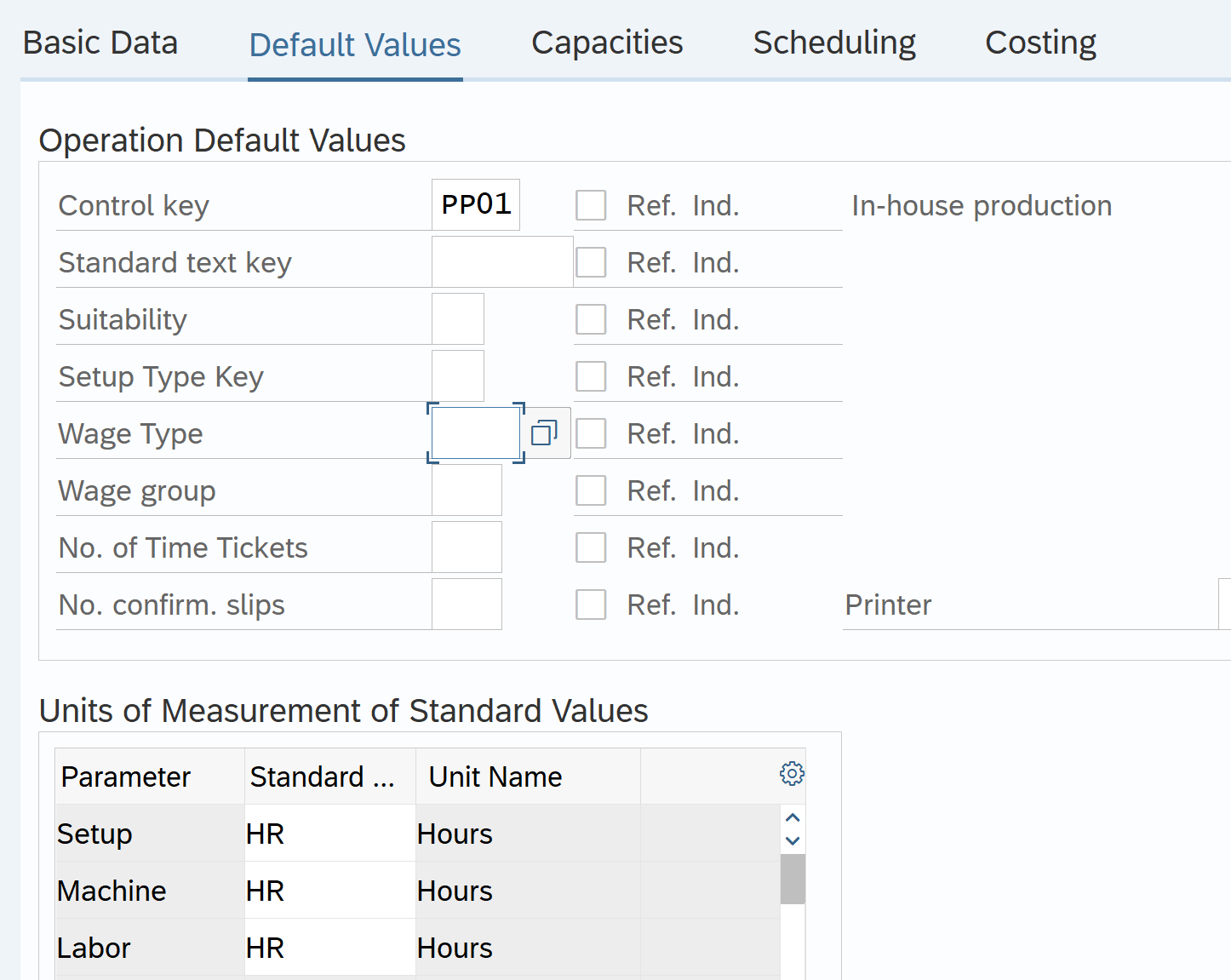

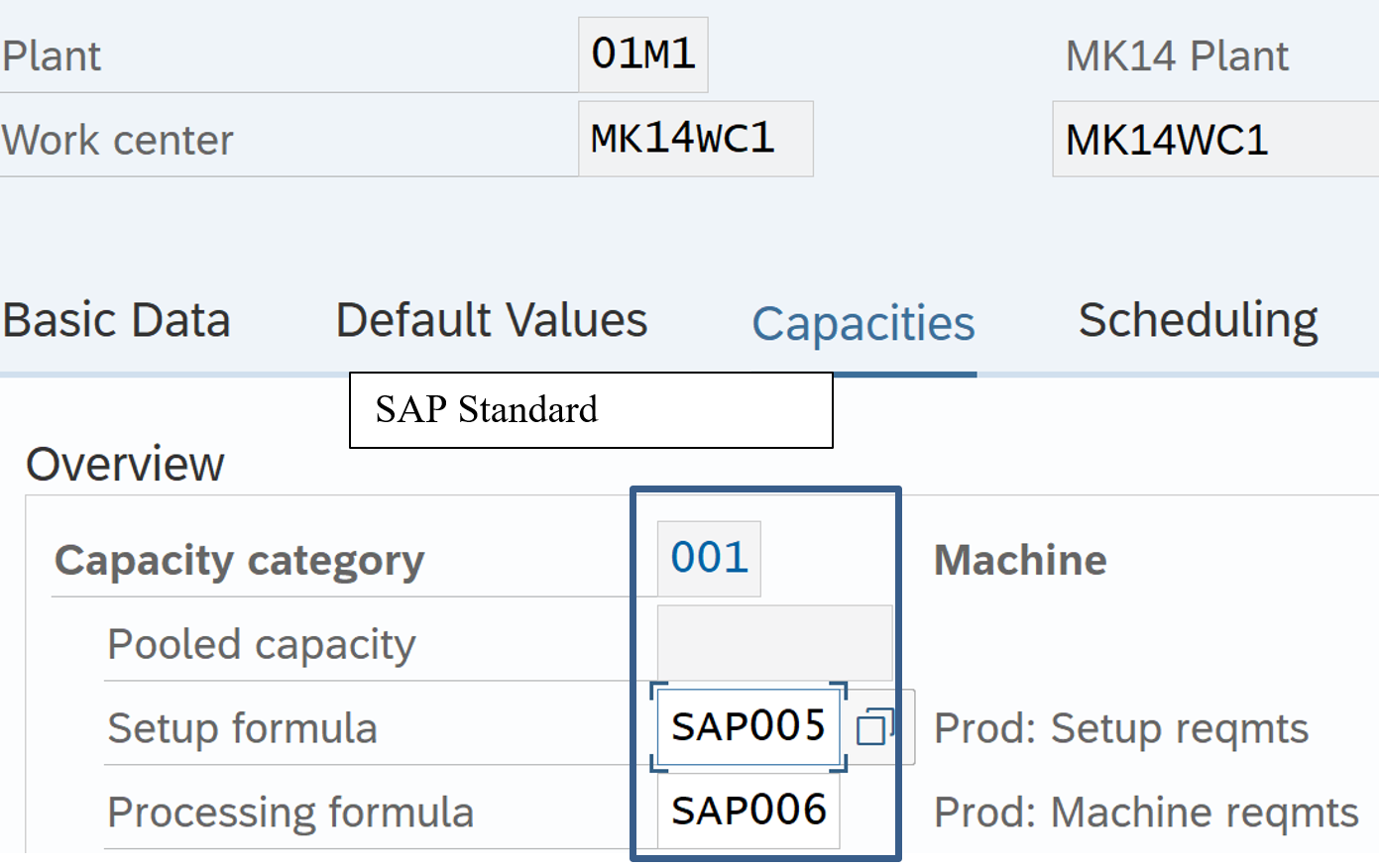

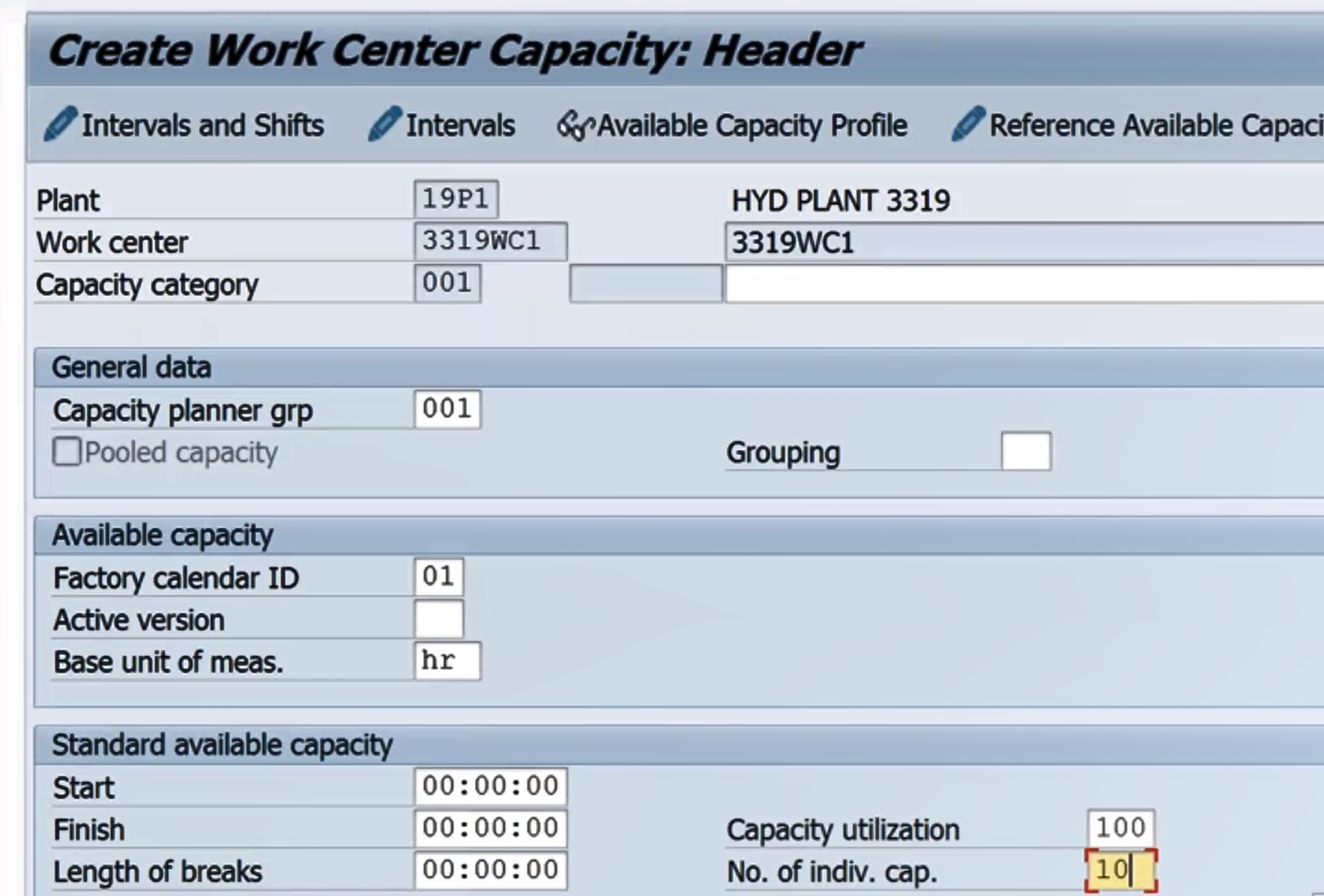

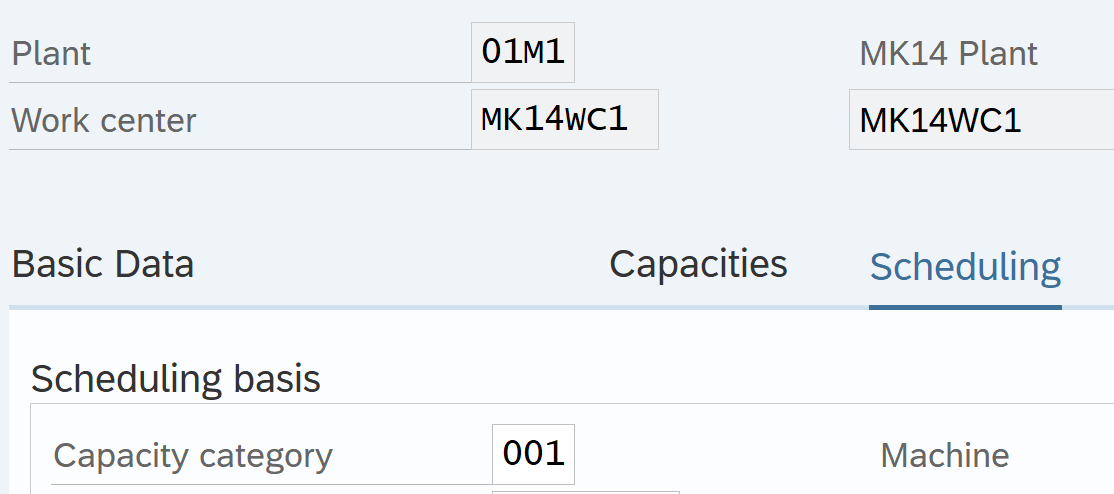

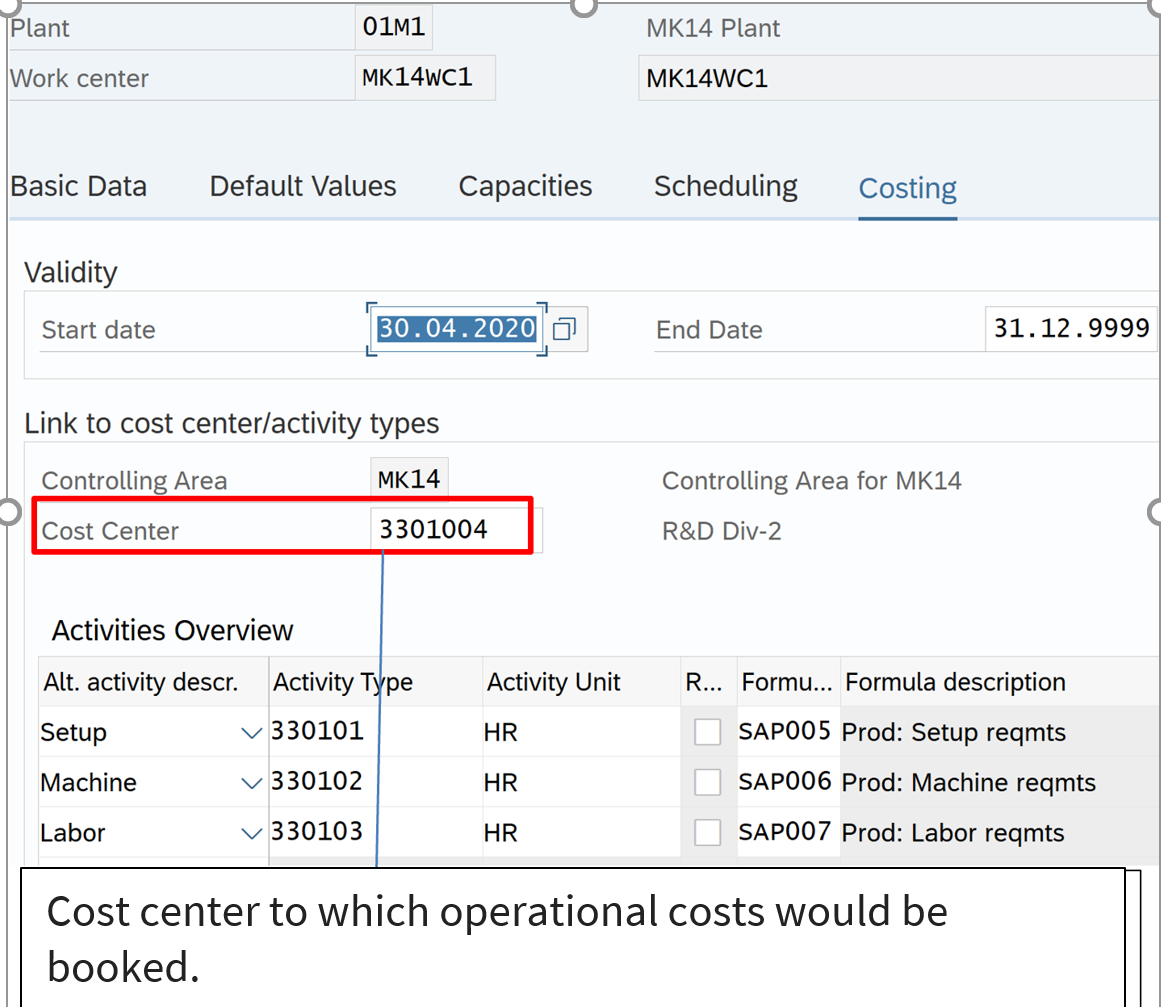

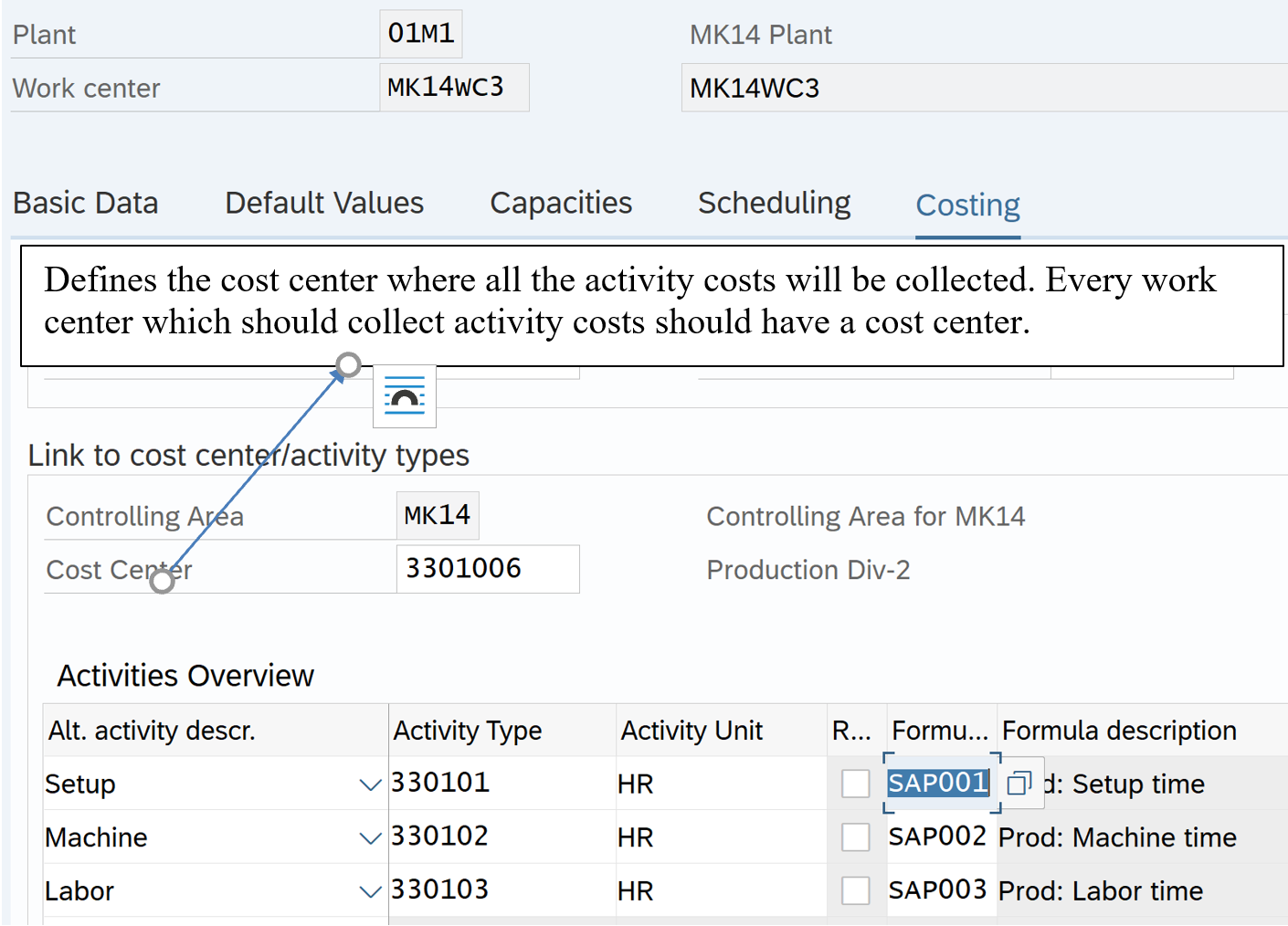

Create Work Center

Tcode: CR01

To hide Person responsible field, go to OPFA – Basic Data – P3000-VERAN – Hide

SAP Default

Below screen appears when press enter on earlier screen

Cost center to which operational costs would be booked.

Similarly create work center 2 and WK Center 3: MK14WC2

Work center MK14WC2 in plant 01M1 was created

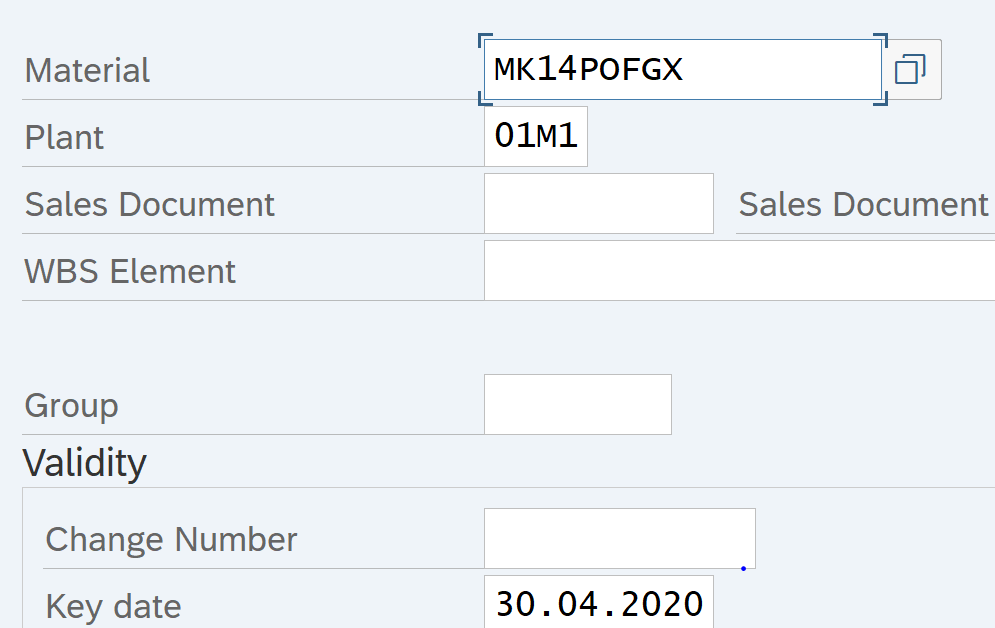

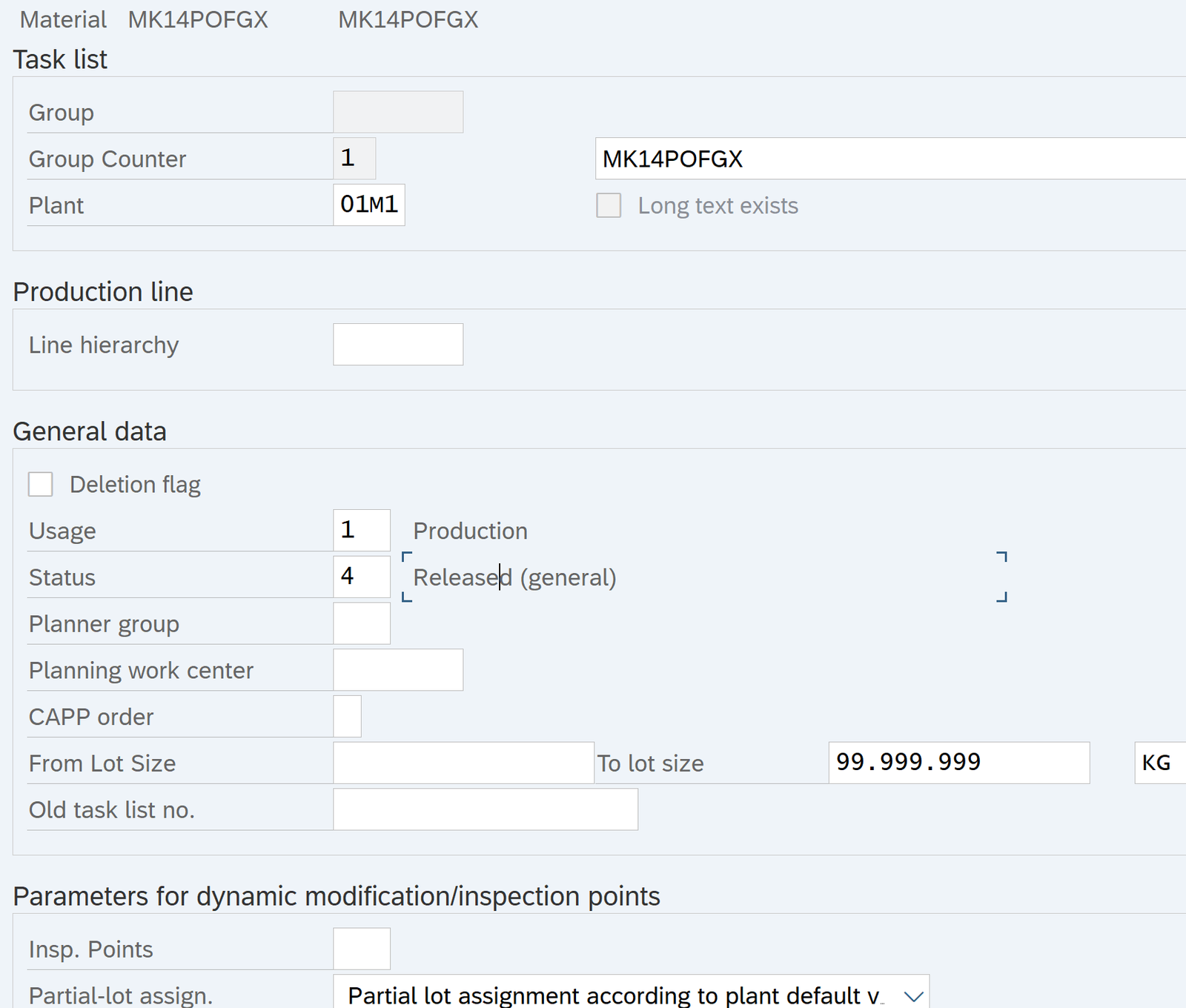

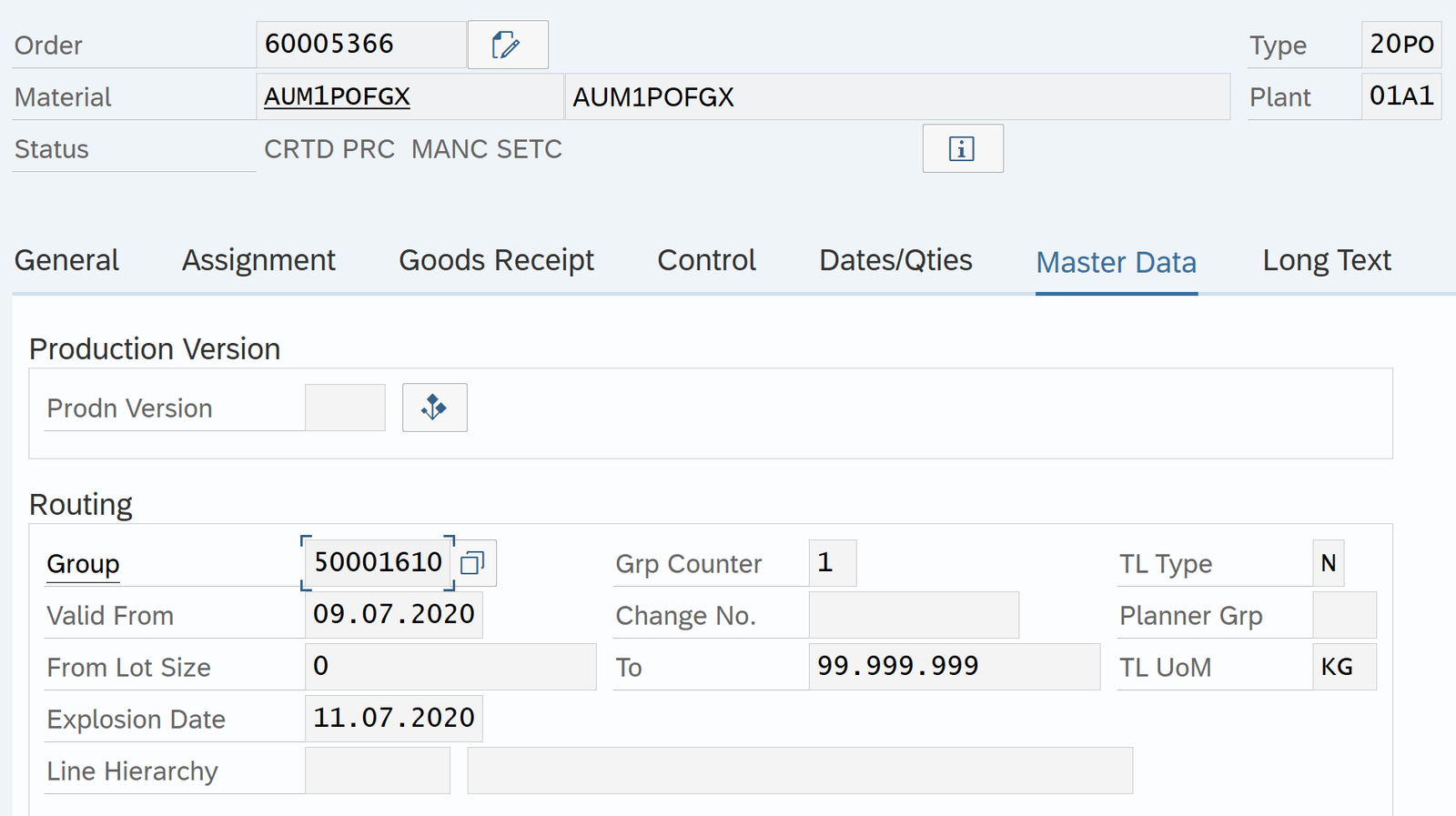

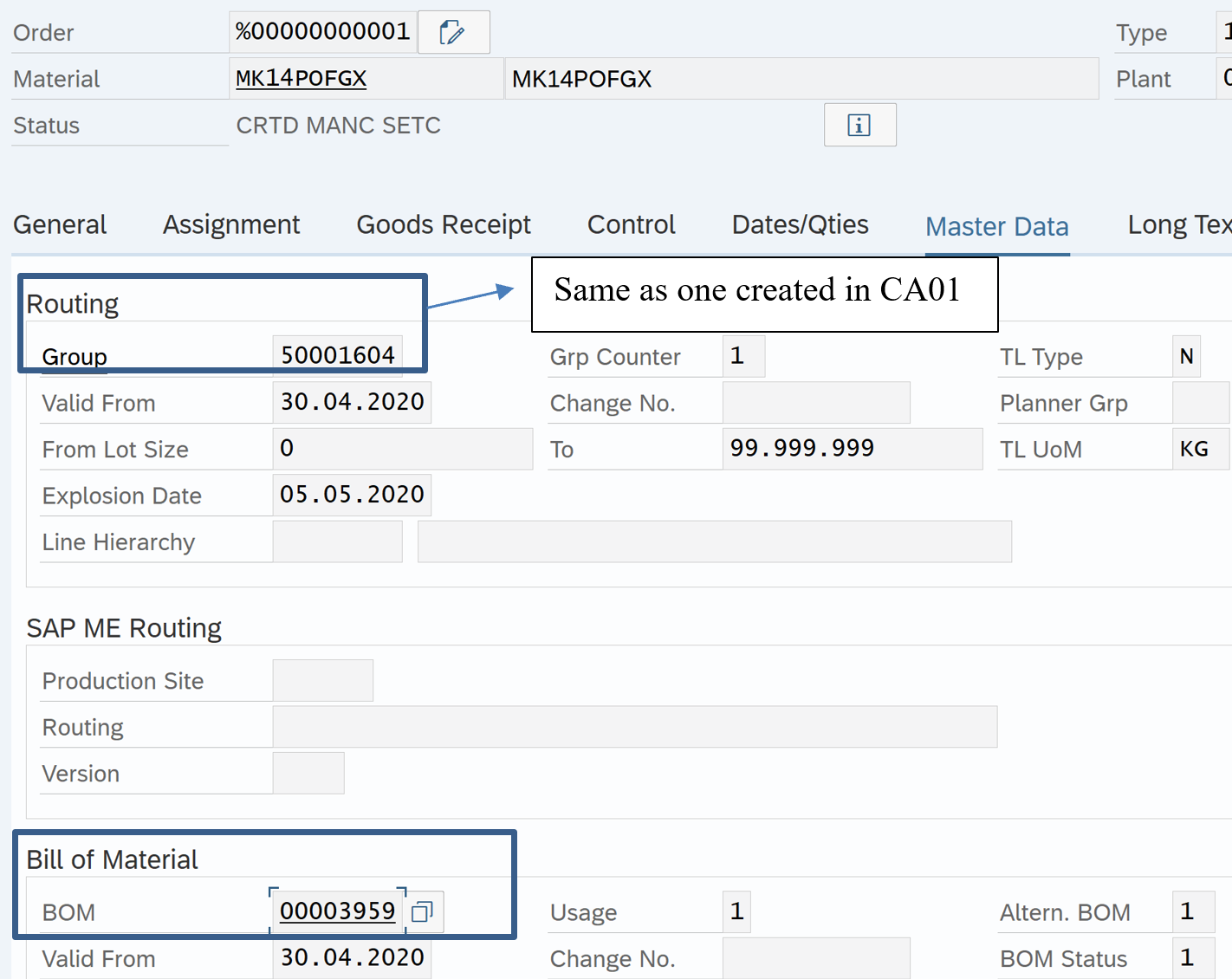

Create Routing

Tcode: CA01

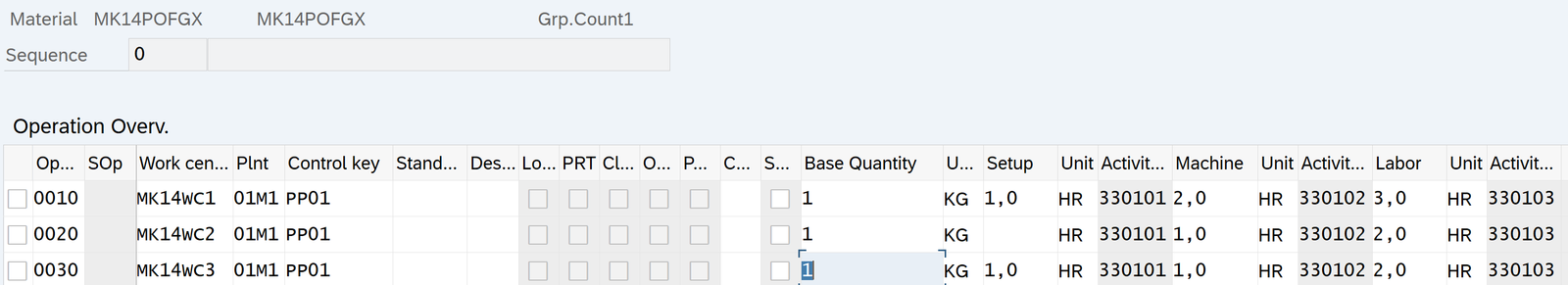

Click Operations tab and enter below data

- Control Key PP01: SAP standard for In House Production. Populated from work center

- Base Unit 1: Quantity of finished goods (MK14POFGX) that will be produced by applying these operations in the work center

- MK14WC1: Work Center 1. Will perform 1 hour of Setup activity, 2 hour of Machine activity and 3 hours of labor to produce one unit of FG

- Similarly, for MK14WC2 and MK14WC3

Routing was saved with group 50001604 and material MK14POFGX.

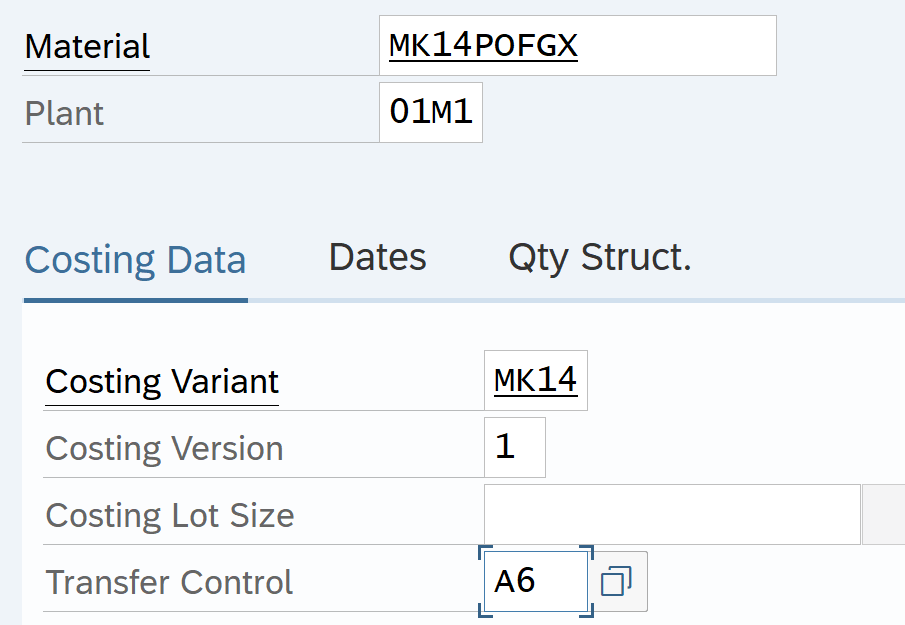

Create Standard Cost

Tcode: CK11N

| BOM : CS01 | ||||

| FGX | Kg | |||

| RMX | 2 | |||

| RMY | 3 | |||

| Routing: CA01 | Setup Activity | M/C Activity | Labor Activity | Work Center |

| Operation 10 | 1 | 2 | 3 | WC 1 |

| Operation 20 | 1 | 2 | WC 2 | |

| Std Cost Estimation | ||||

| Raw Material | Kg | Avg Price | Total | |

| RMX | 2 | 300 | 600 | |

| RMY | 3 | 400 | 1200 | |

| Total Price RMX +RMY | 1800 | |||

| Operation 10 (Price from KSBT) | Hours | Rate/Hr/EUR | Total | |

| Setup | 1 | 470 | 470 | |

| Machine | 2 | 294 | 588 | |

| Labor | 3 | 285 | 855 | |

| Total Price OP 10 | 1913 | |||

| Operation 20 | ||||

| Setup | – | |||

| Machine | 1 | 294 | 294 | |

| Labor | 2 | 285 | 570 | |

| Total Price OP 20 | 864 | |||

| OH (Valuation variant : OKKN) | ||||

| MOH | 10% | 1800 | 180 | |

| AOH | 15% | 2777 | 417 | |

| Total OH Price / Kg | 597 | |||

| Standard Cost Estimation for 1 Kg | 5174 |

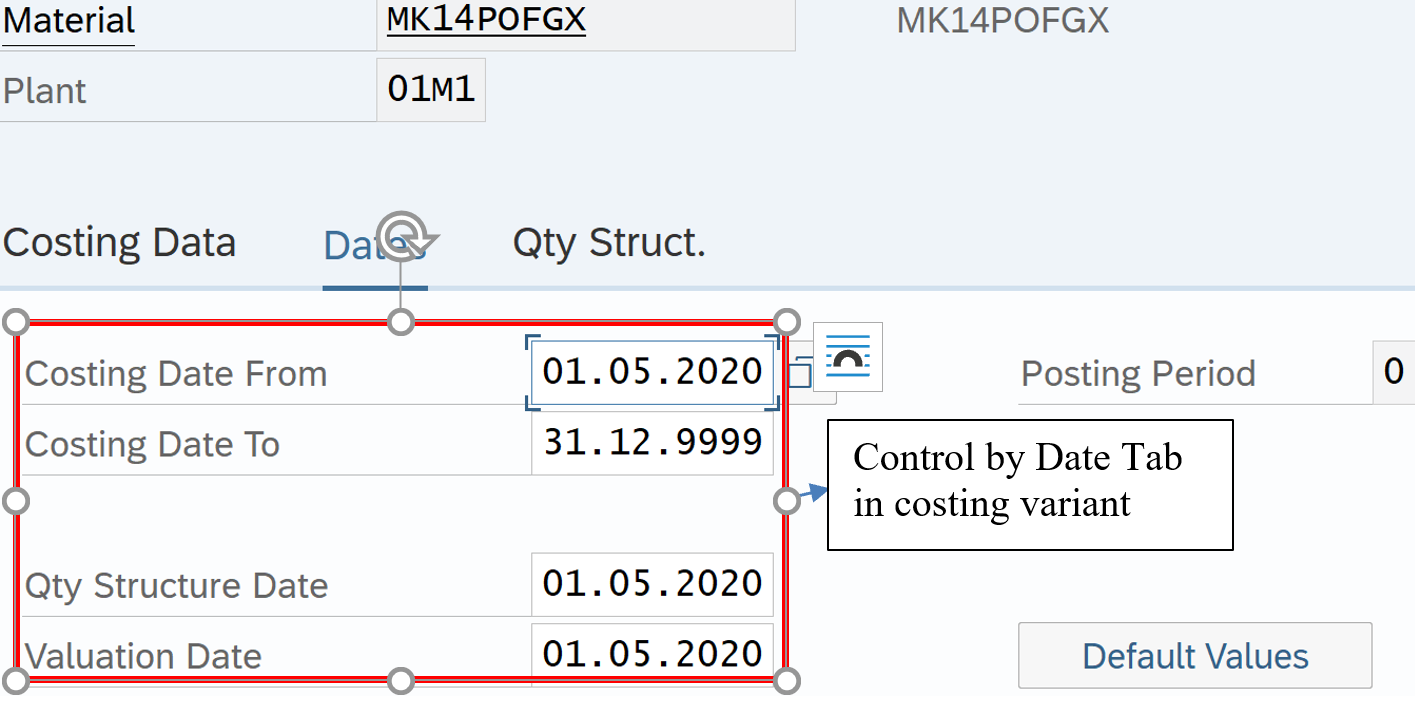

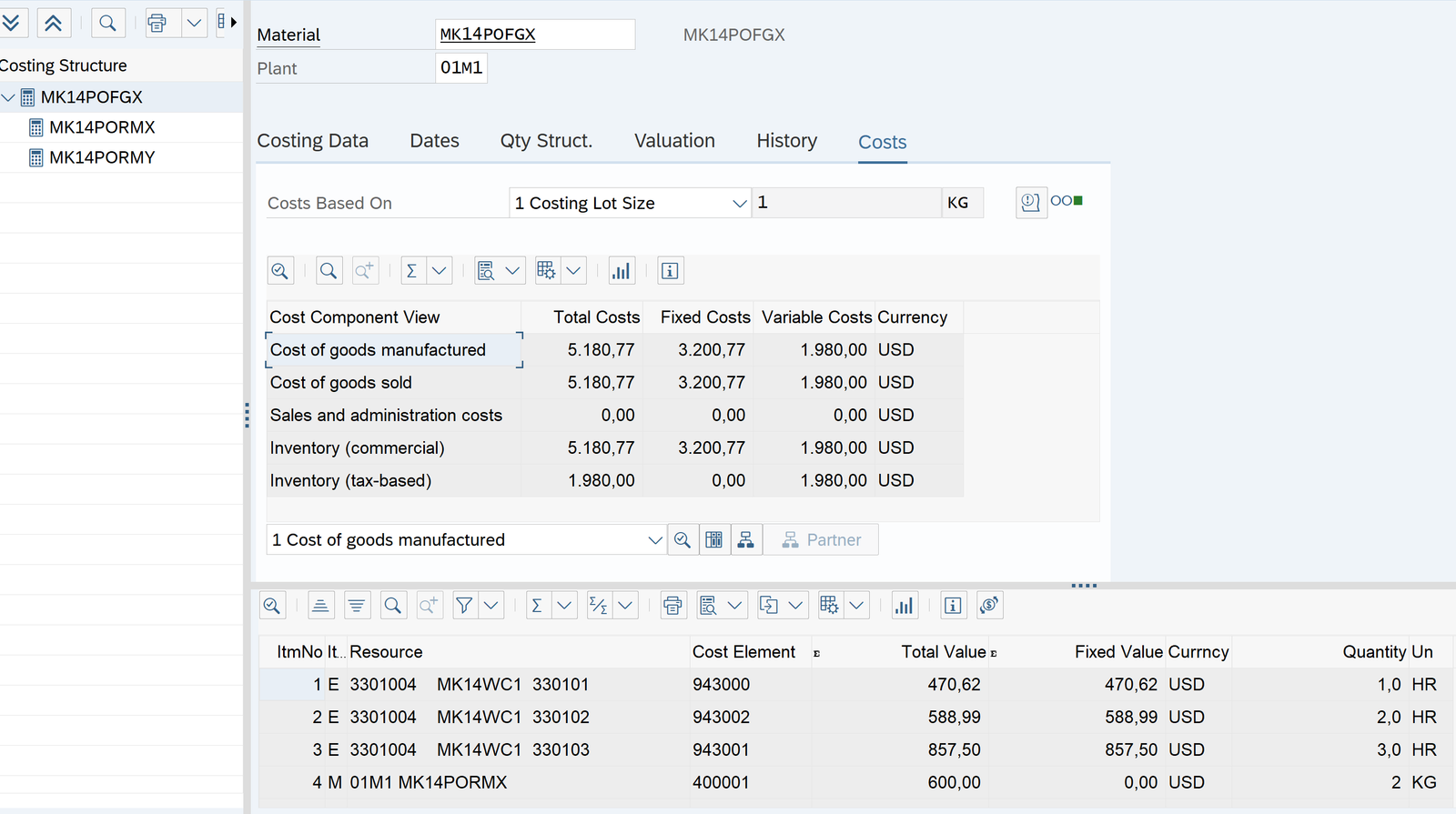

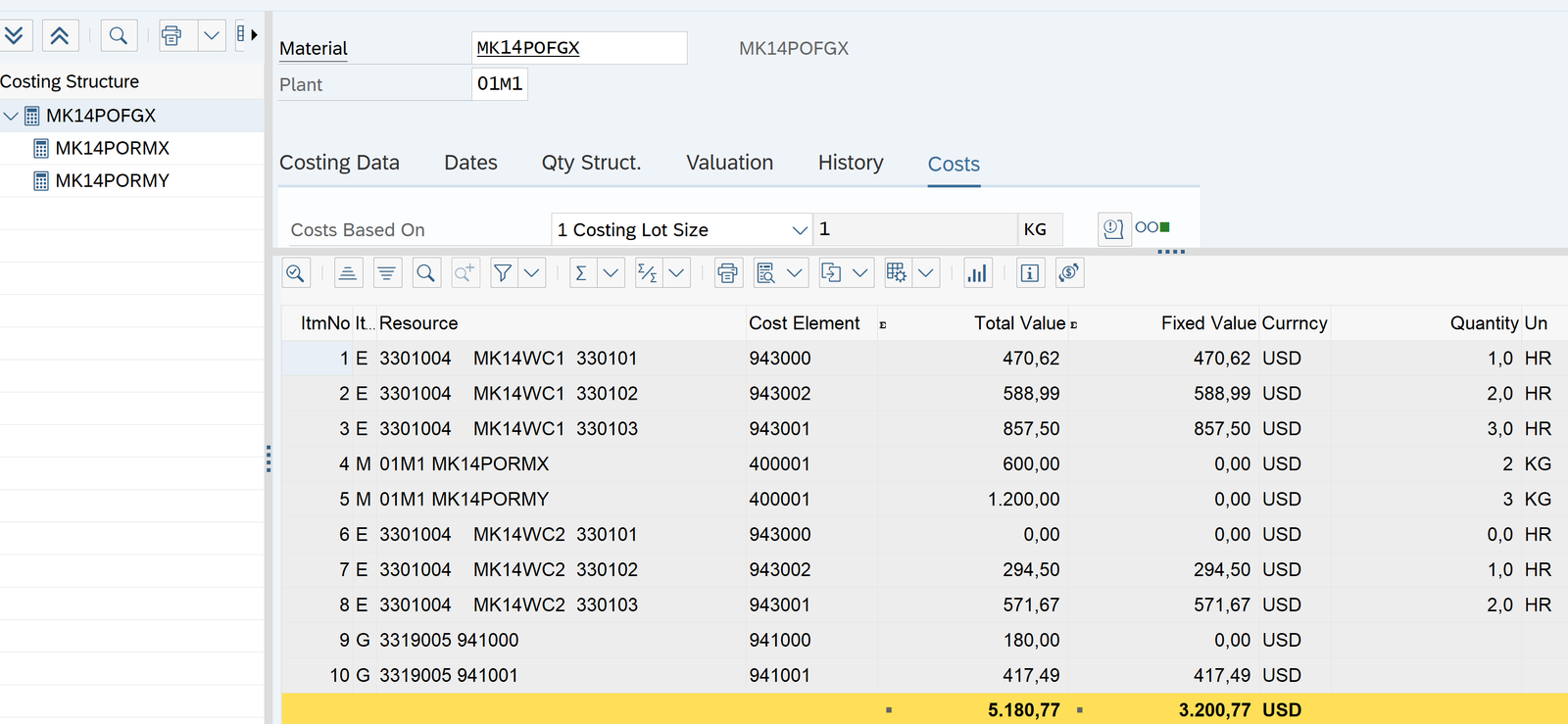

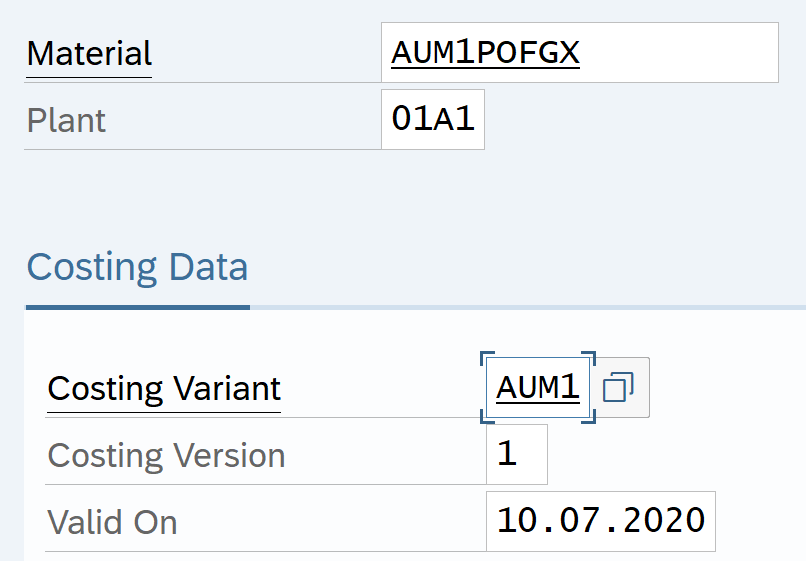

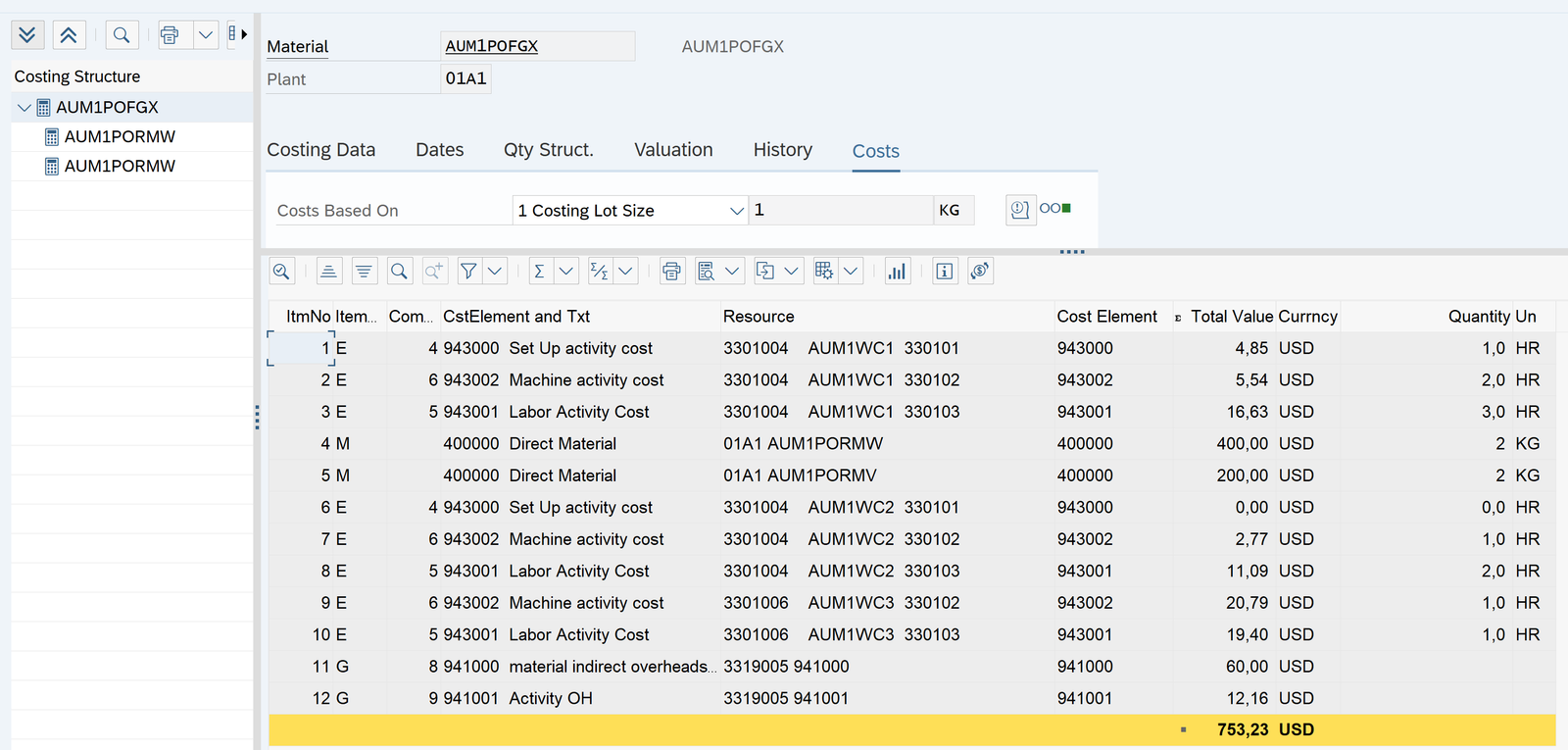

Create Standard Cost Estimate

Tcode: CK11N

Select for detailed itemized view

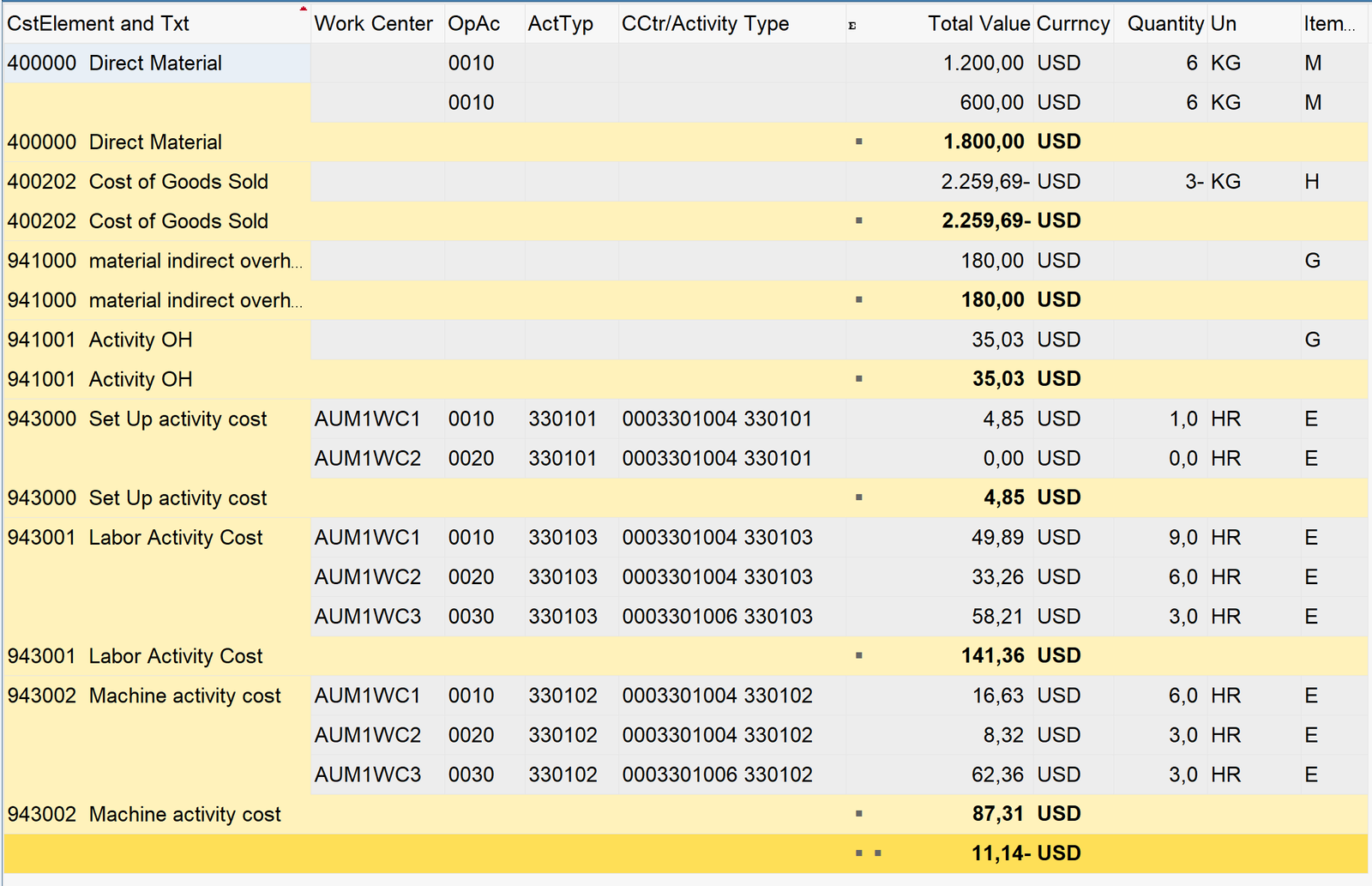

Itemized Product Cost

Calculated Value in the excel

| BOM : CS01 | ||||

| FGX | Kg | |||

| RMX | 2 | |||

| RMY | 3 | |||

| Routing: CA01 | Setup Activity | M/C Activity | Labor Activity | Work Center |

| Operation 10 | 1 | 2 | 3 | WC 1 |

| Operation 20 | 1 | 2 | WC 2 | |

| Std Cost Estimation | ||||

| Raw Material | Kg | Avg Price | Total | |

| RMX | 2 | 300 | 600 | |

| RMY | 3 | 400 | 1200 | |

| Total Price RMX +RMY | 1800 | |||

| Operation 10 (Price from KSBT) | Hours | Rate/Hr/EUR | Total | |

| Setup | 1 | 470 | 470 | |

| Machine | 2 | 294 | 588 | |

| Labor | 3 | 285 | 855 | |

| Total Price OP 10 | 1913 | |||

| Operation 20 | ||||

| Setup | – | |||

| Machine | 1 | 294 | 294 | |

| Labor | 2 | 285 | 570 | |

| Total Price OP 20 | 864 | |||

| OH (Valuation variant : OKKN) | ||||

| MOH | 10% | 1800 | 180 | |

| AOH | 15% | 2777 | 417 | |

| Total OH Price / Kg | 597 | |||

| Standard Cost Estimation for 1 Kg | 5174 |

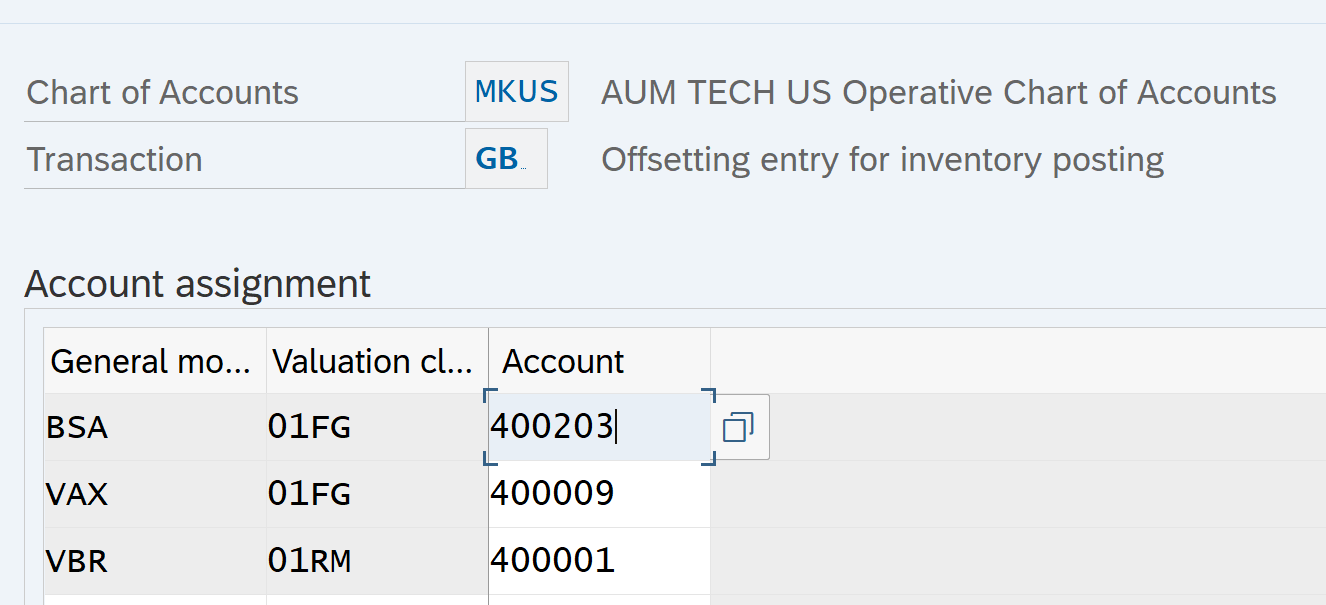

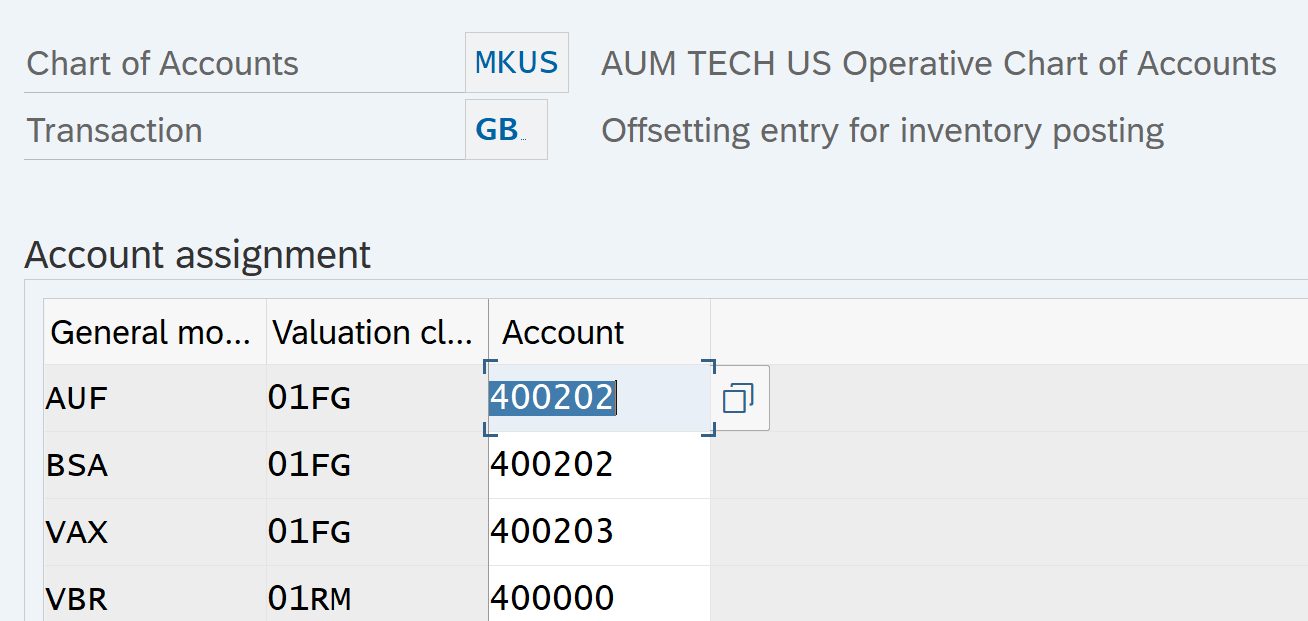

If error add below entries in OBYC – GBB

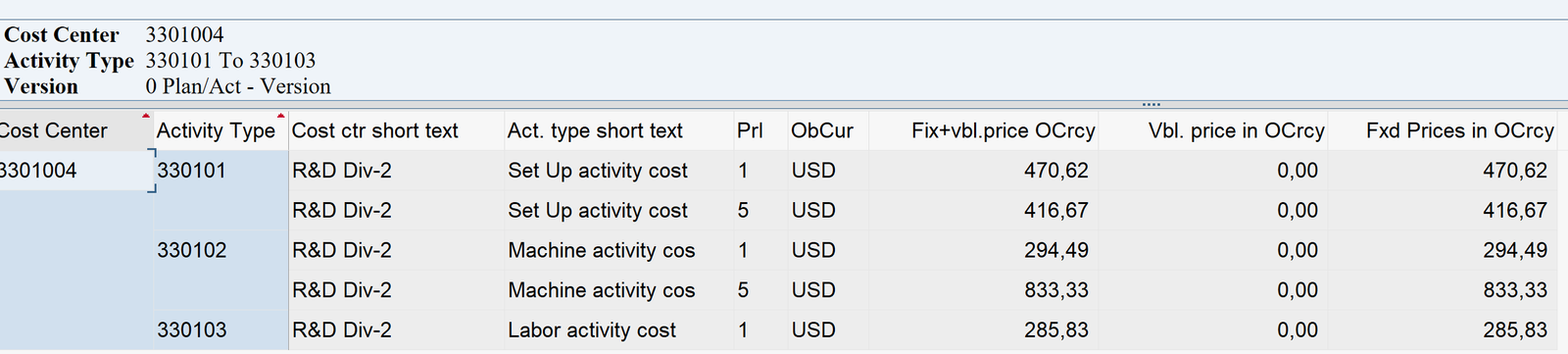

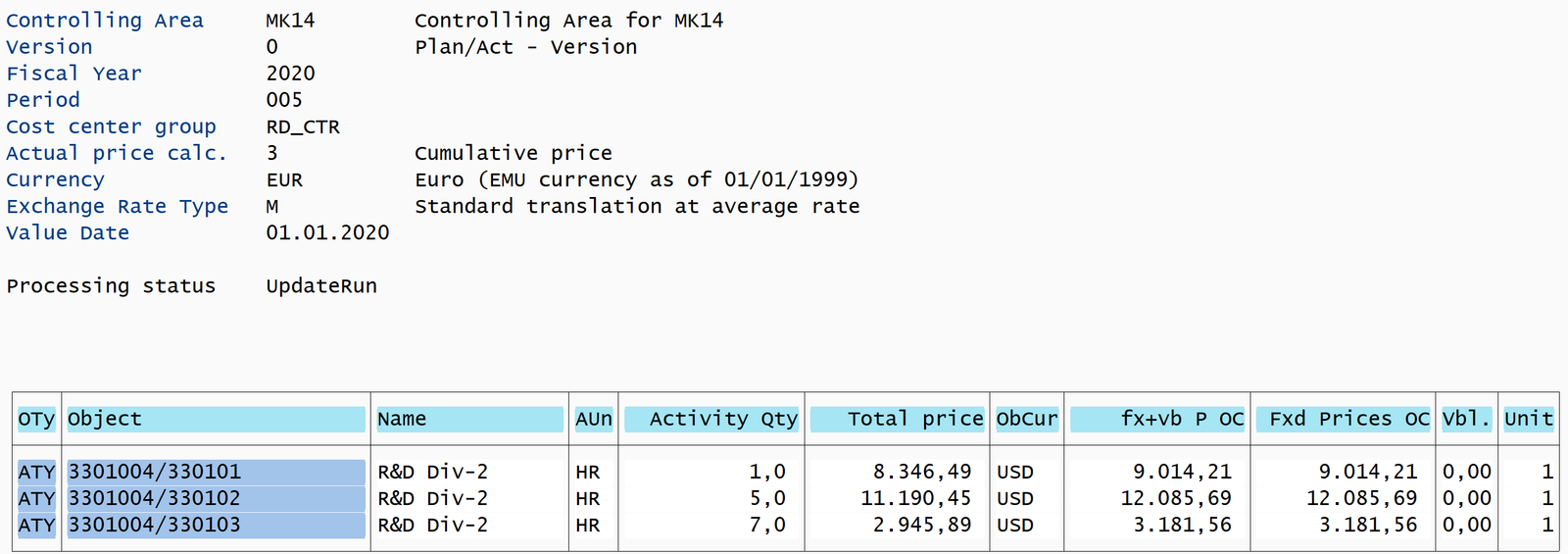

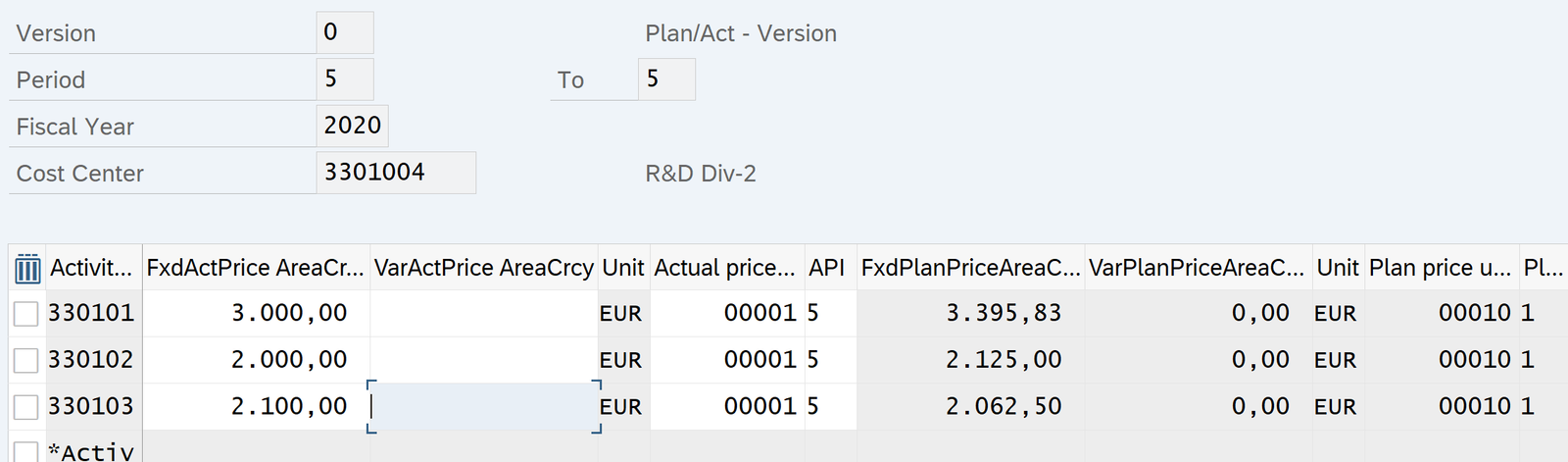

KSBT

Per Unit price match

| 330101 | Set Up activity cost | 470 |

| 330102 | Machine activity cost | 294 |

| 330103 | Labor activity cost | 285 |

Prl: 1 : Planned Price

Prl 5: Actual Price

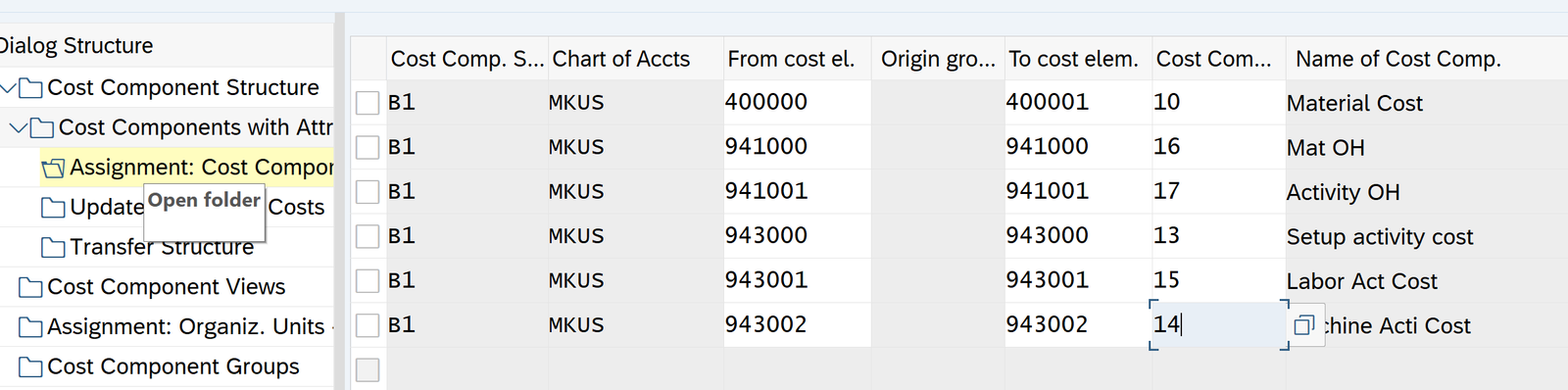

OKTZ ( Cost Component Structure to check errors)

If error in log don’t save. Material can be re costed. It cannot be re costed after saving

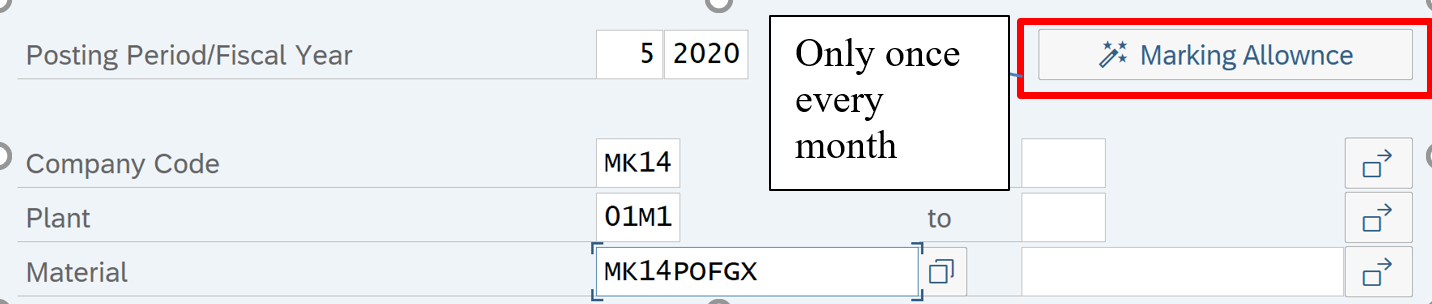

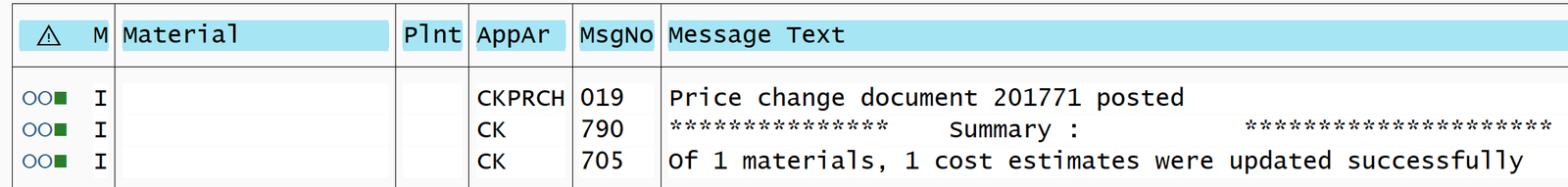

Mark and Release Standard Cost Estimation

Transaction code: CK24

| Mark | Standard cost updated as future price in costing tab 2 |

| Release | Future price now becomes current price in costing tab 2 |

| Standard cost updated as standard cost in accounting tab 1 in MM02 |

May have to close MM period in MMPV

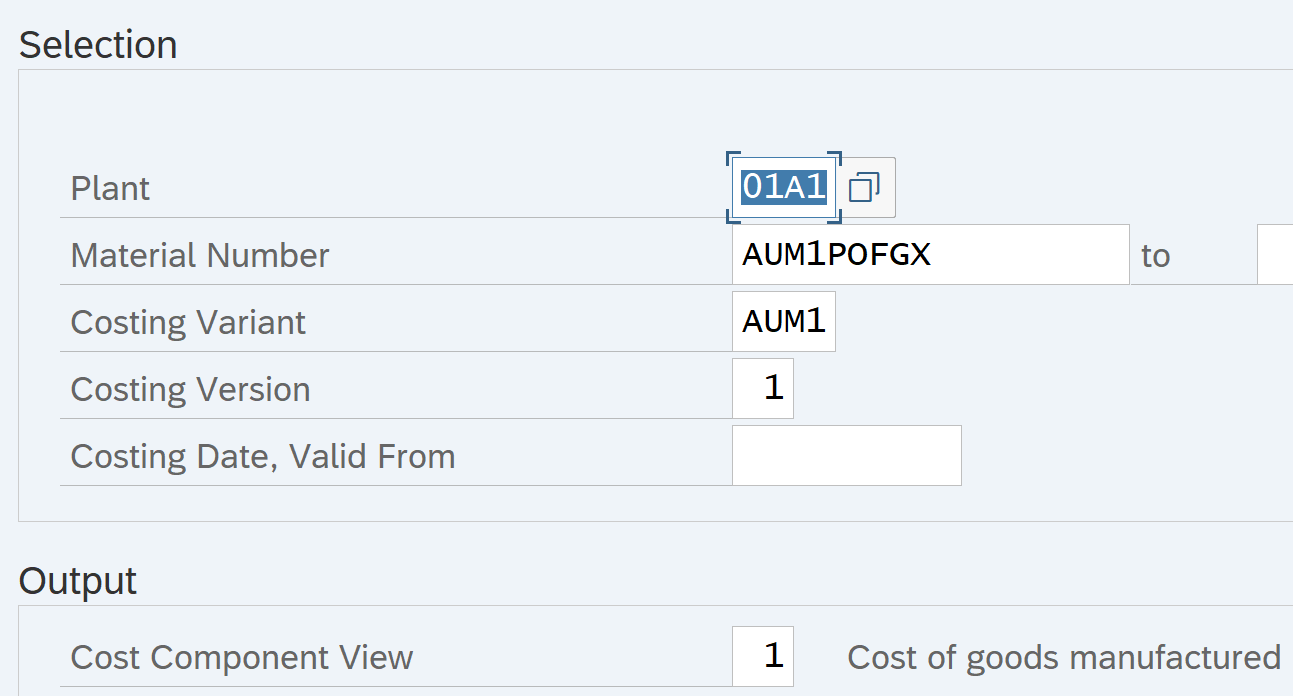

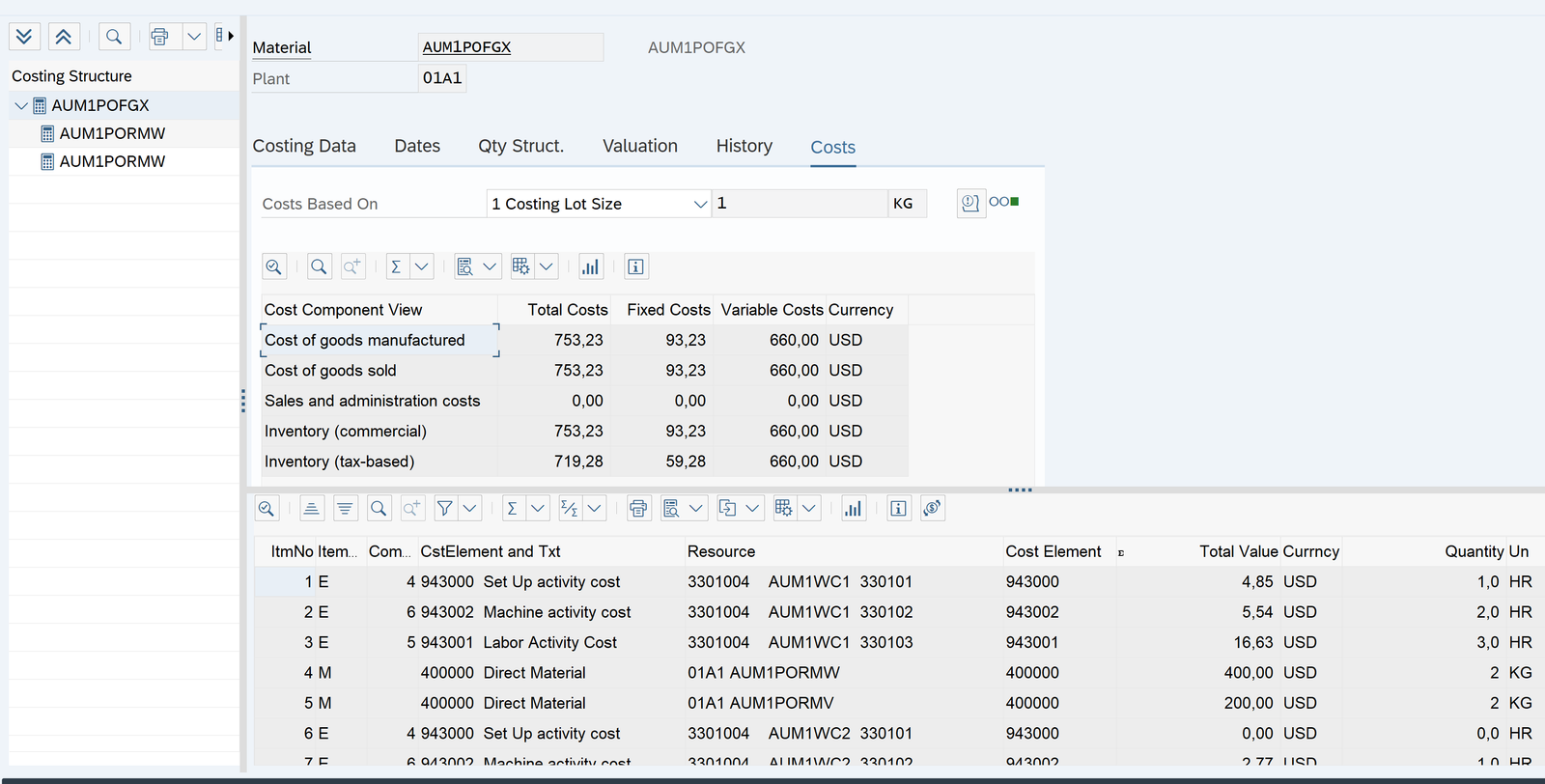

Display Standard cost with cost component structure

Transaction Code: CK13N

Standard Cost Report: S_P99_41000111

Standard Cost Report: S_P99_41000111

Product Costing Tables

| s.no. | Tables | Description |

| 1 | KEKO | Product Costing – Header Data |

| 2 | CKIS | Items Unit Costing/Itemization Product Costing |

Product Costing – Actual Cost

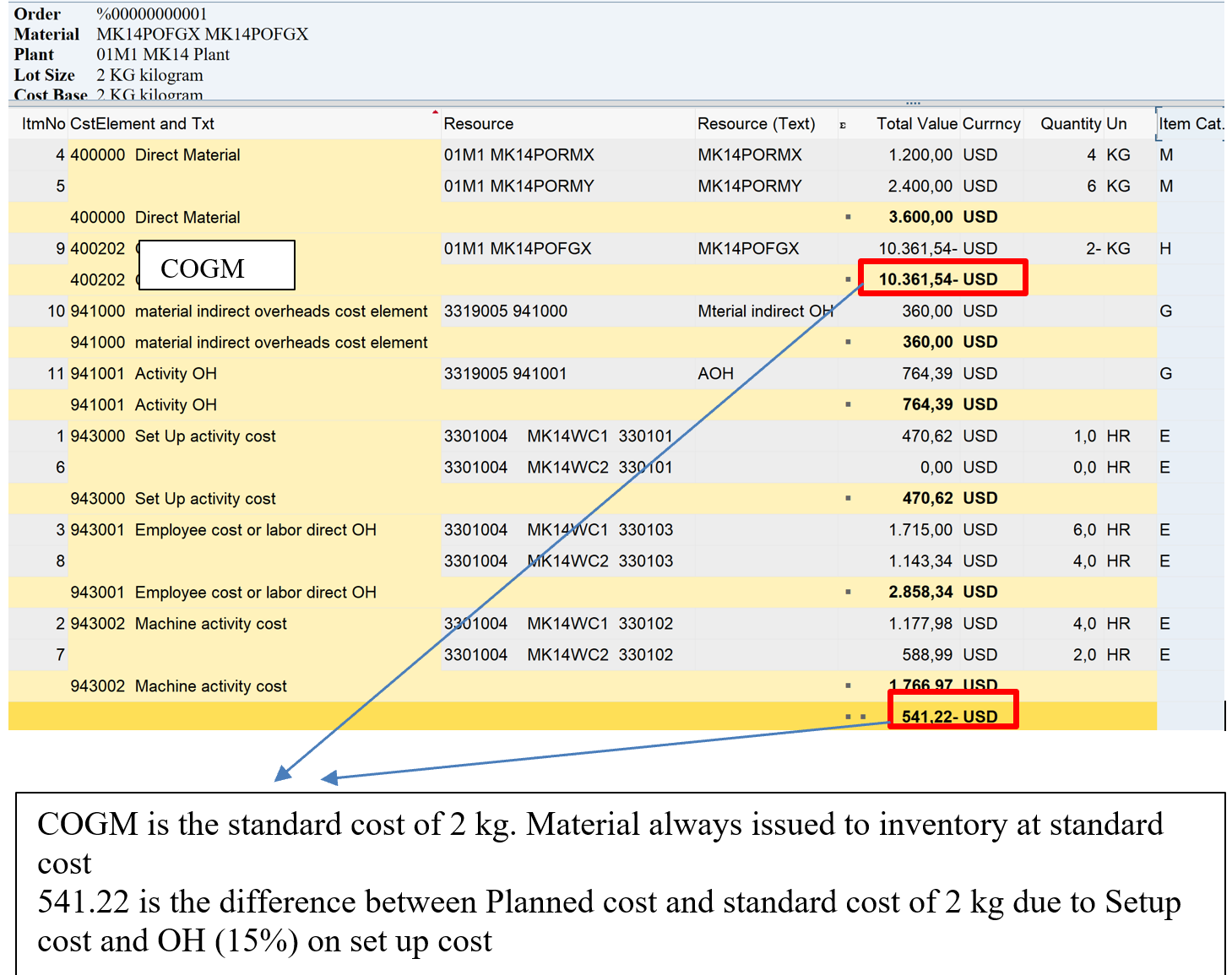

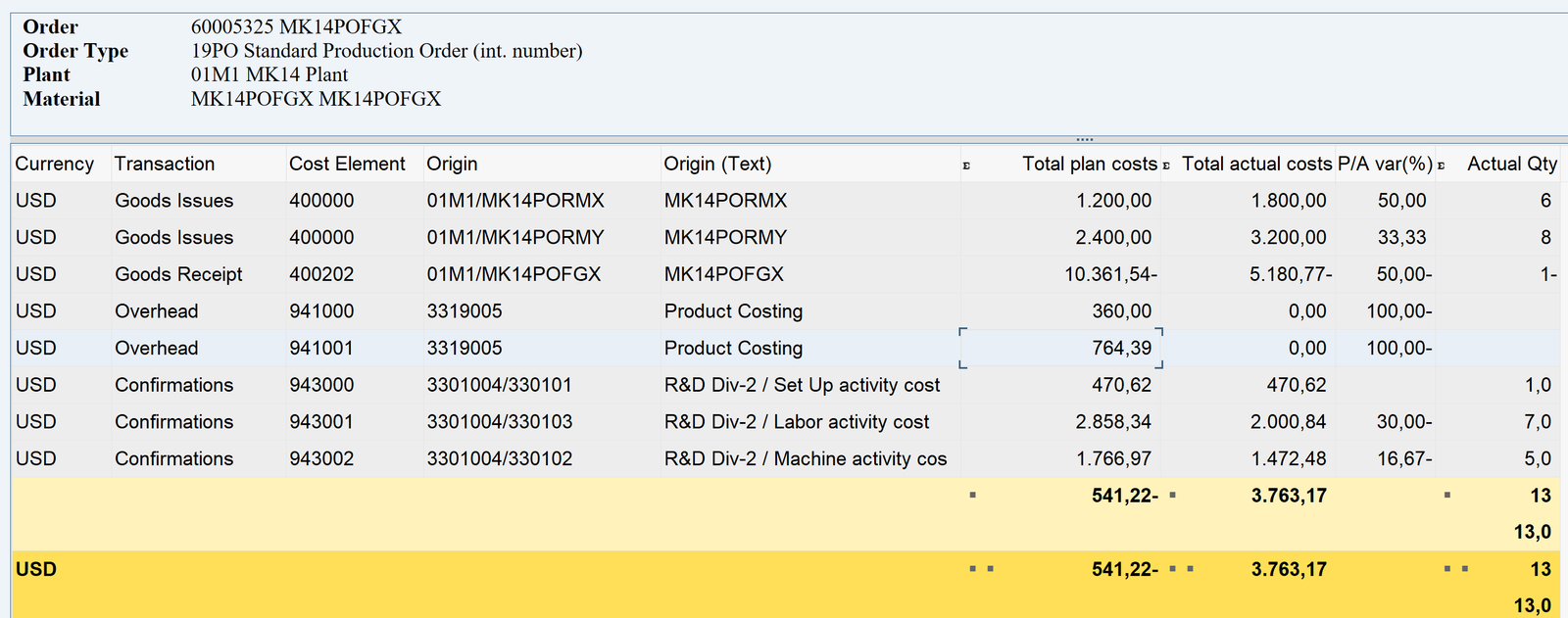

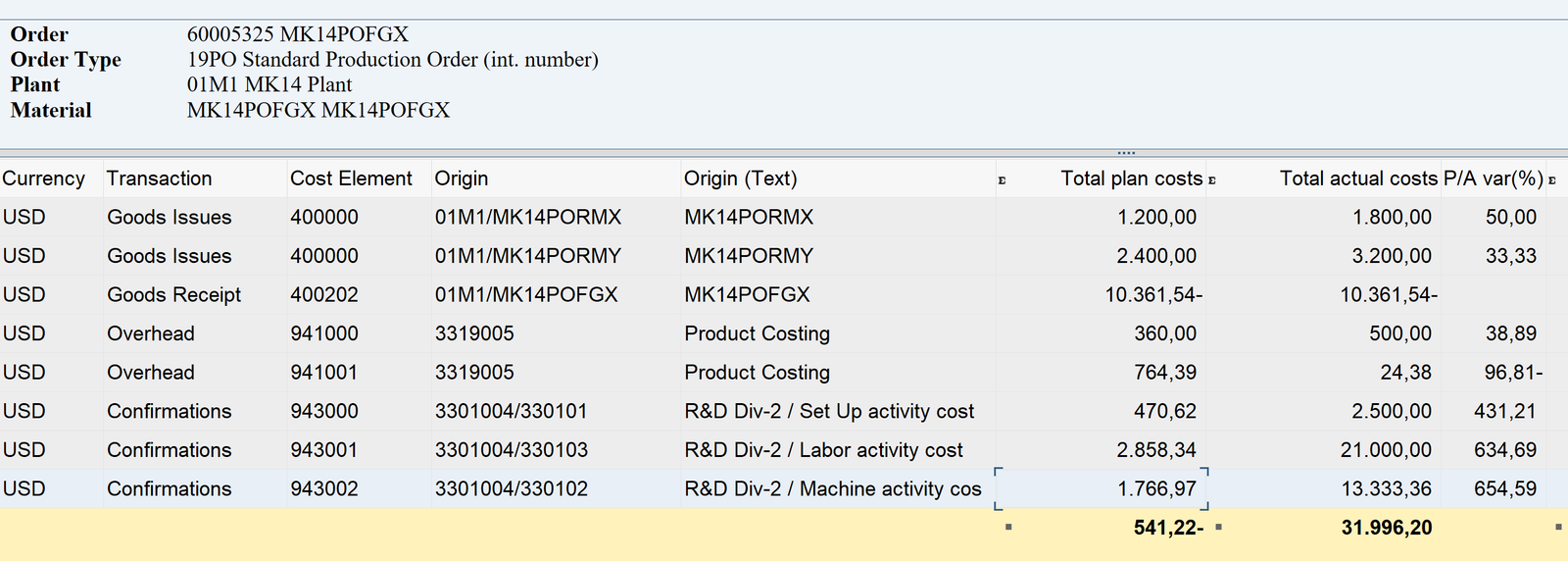

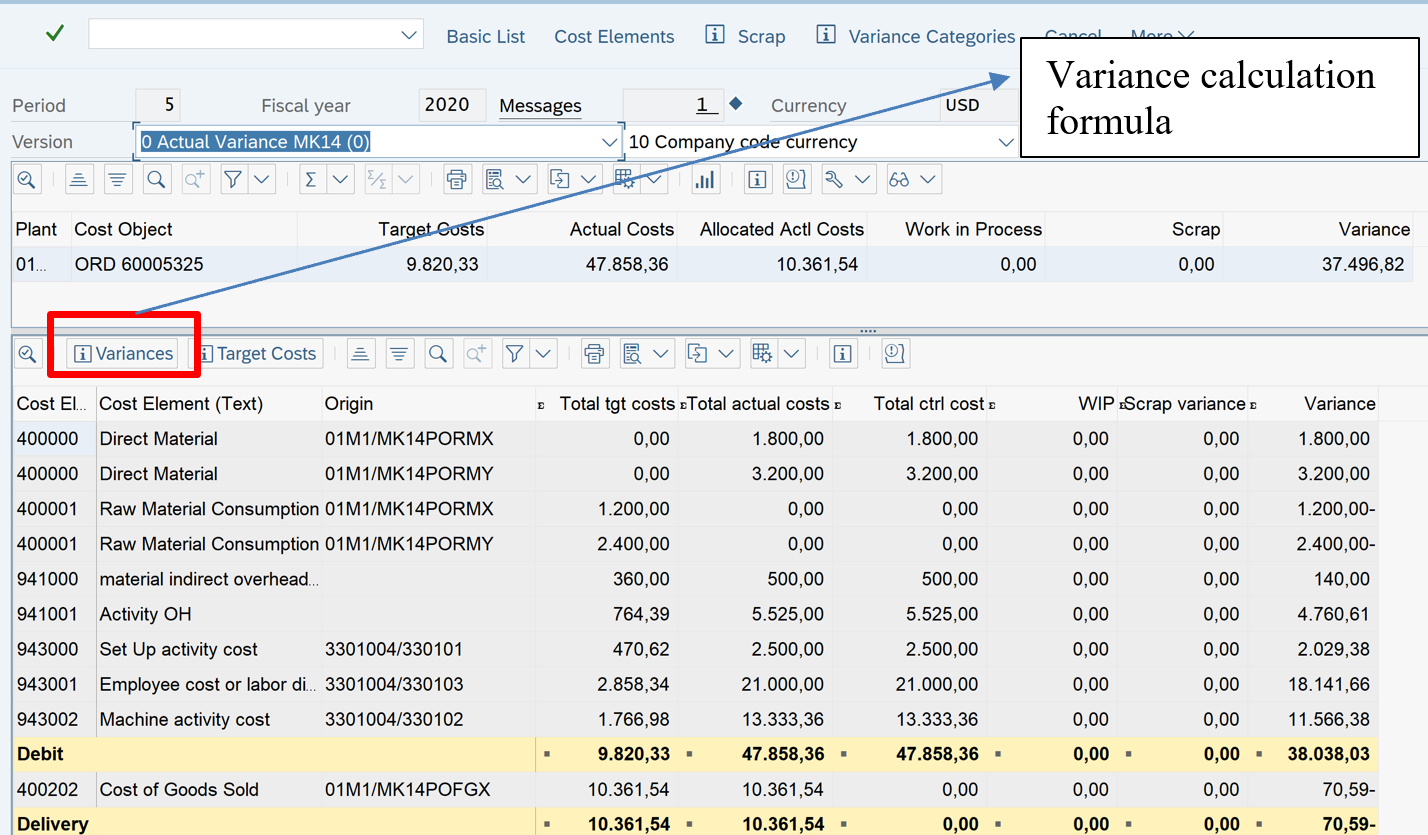

We have calculated standard / estimated cost of FG. Now we will create a Production Order and calculate actual cost of FG. Difference between actual cost and Standard / estimated cost will be the variance

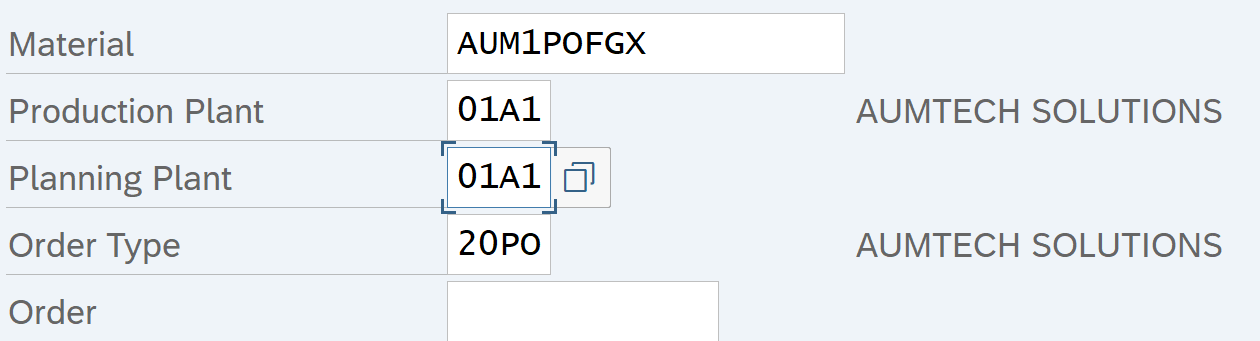

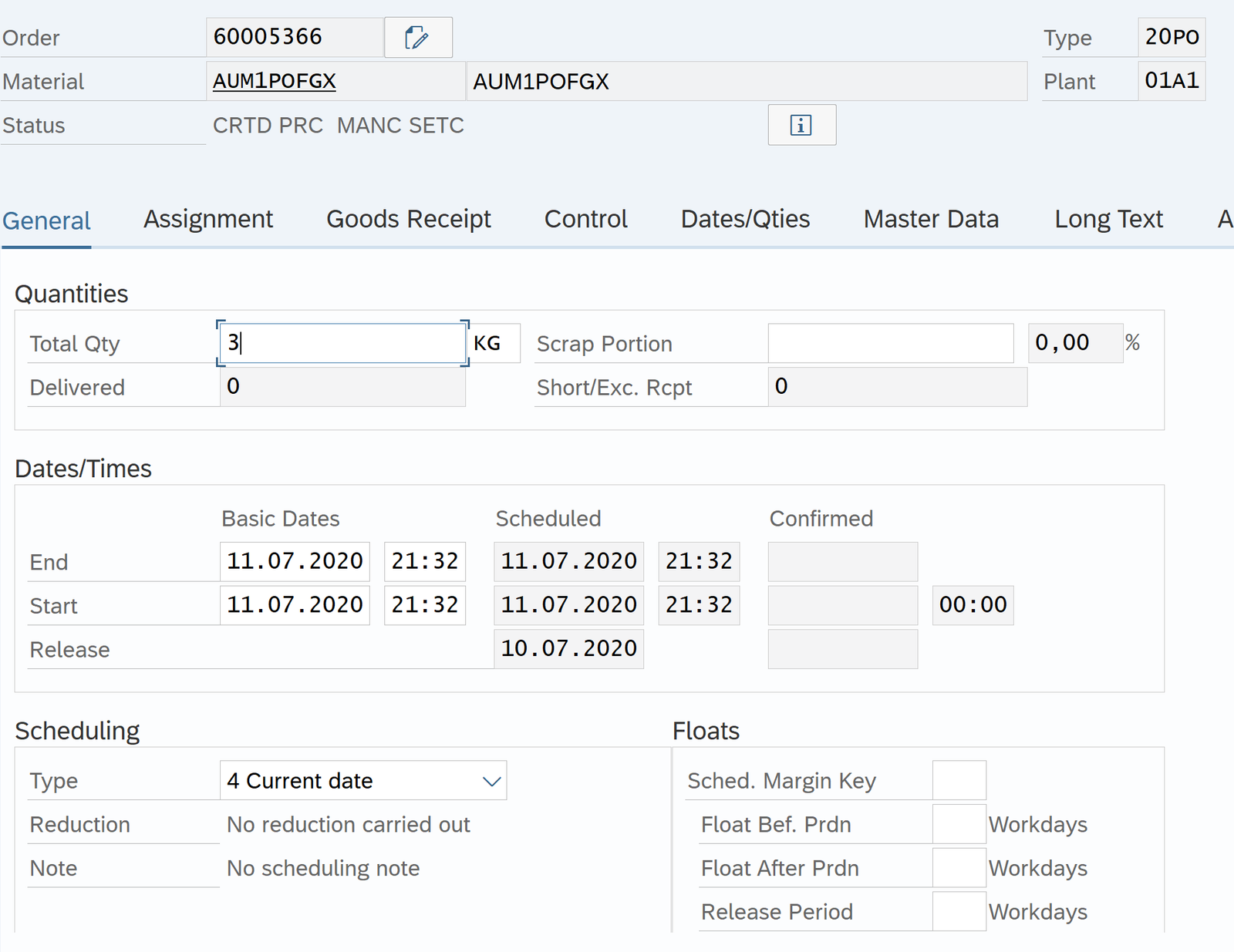

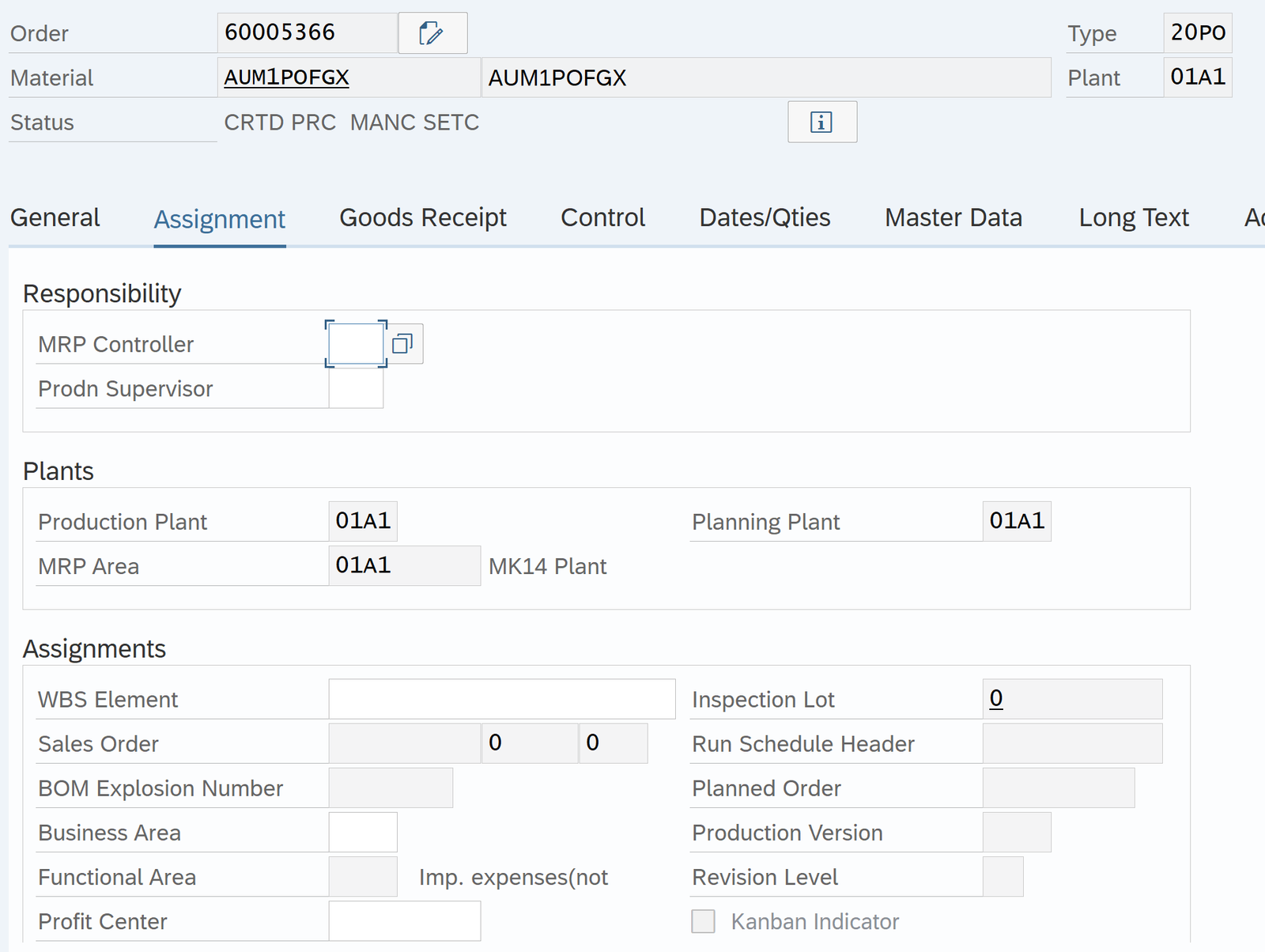

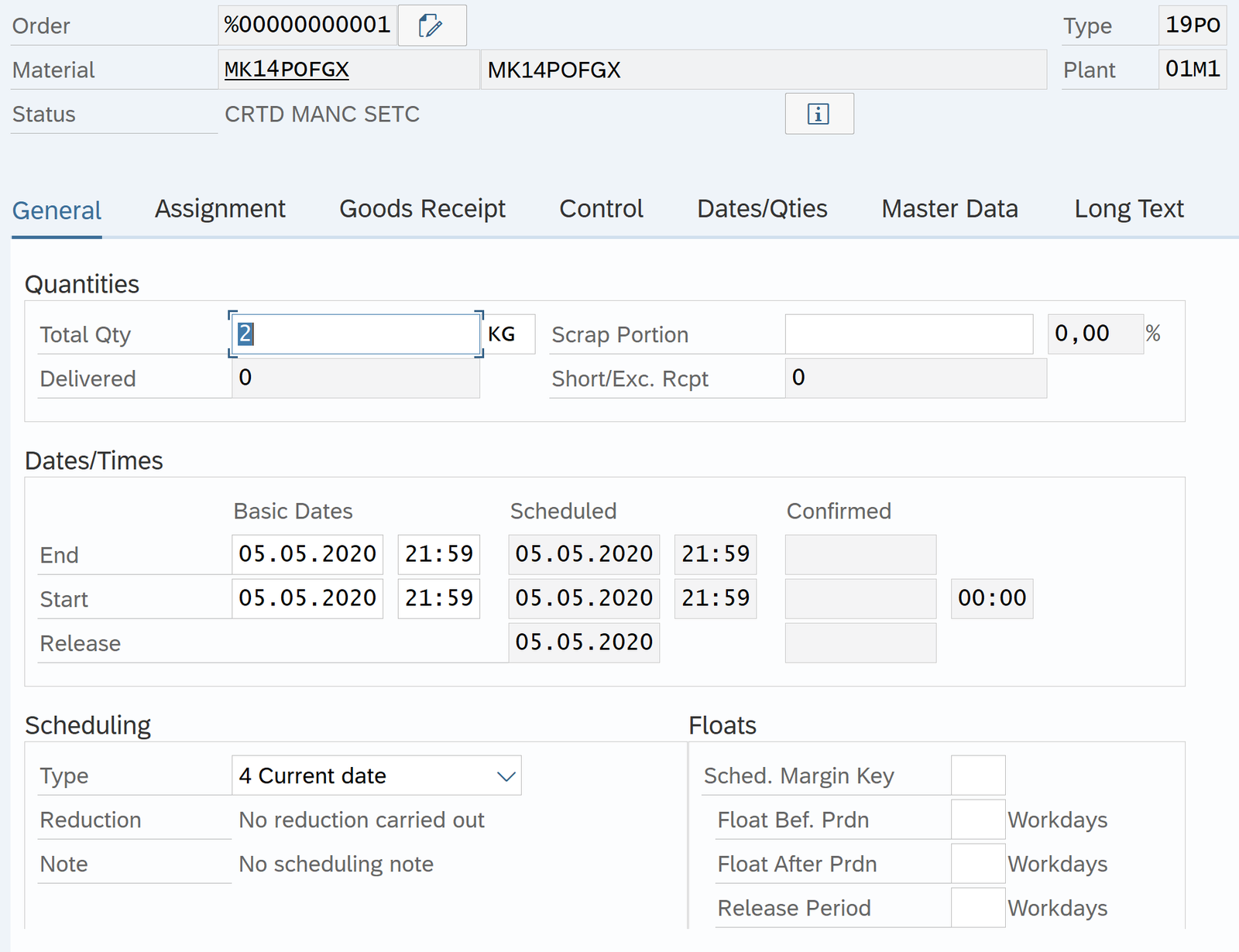

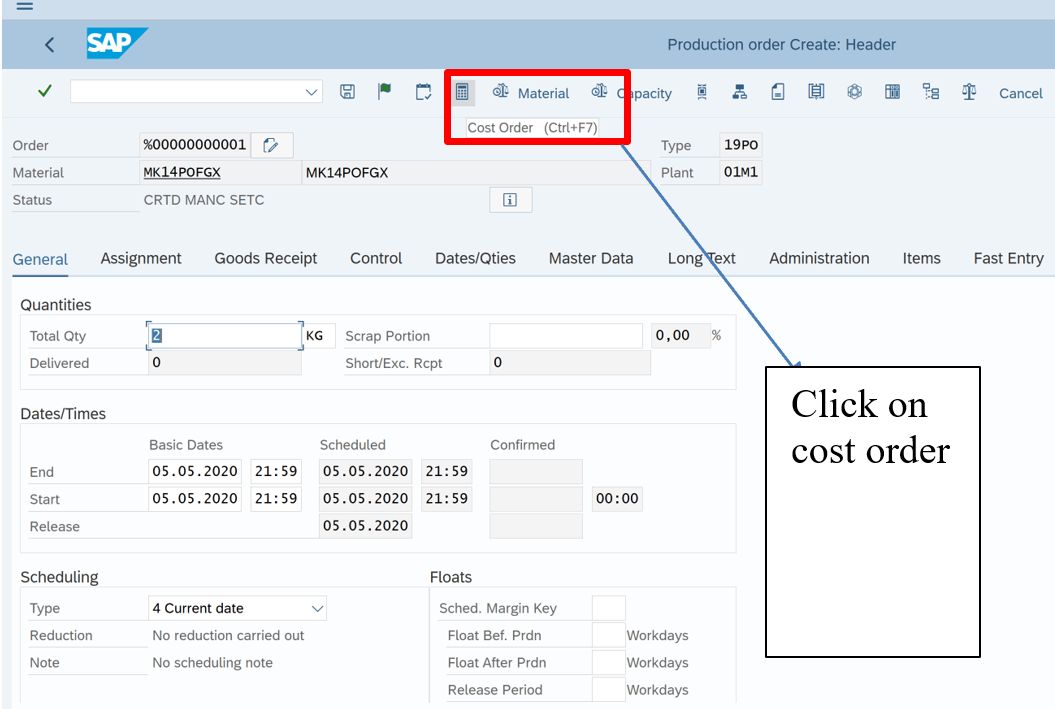

Create Production Order: CO01

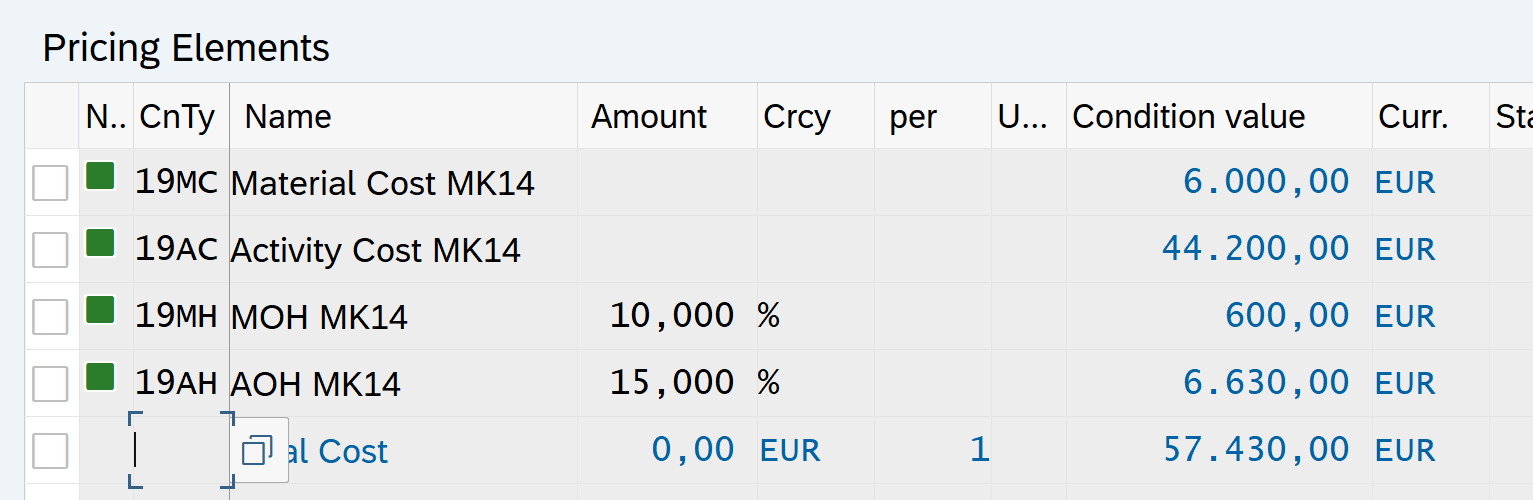

Now click Cost Order button. This will calculate the Planned cost of the Production Order. Standard cost is always for 1 unit. Planned cost is for the total production order unit (3 kg in this case). Thus, FC per unit differ between standard cost and planned cost

Click Goto – Cost – Itemization to view the planned cost

Planned cost Material = 2 Kg (BOM) * 3 Kg (Prod Order) = 1800

Planned cost Material OH = 10% OF 1800 (Costing Sheet) = 180

Planned cost activity OH = 15% of total activity cost (268) = 35

COGM / COGS = 3 (Prod Order Qty) * Standard Cost (753.23) = 2259

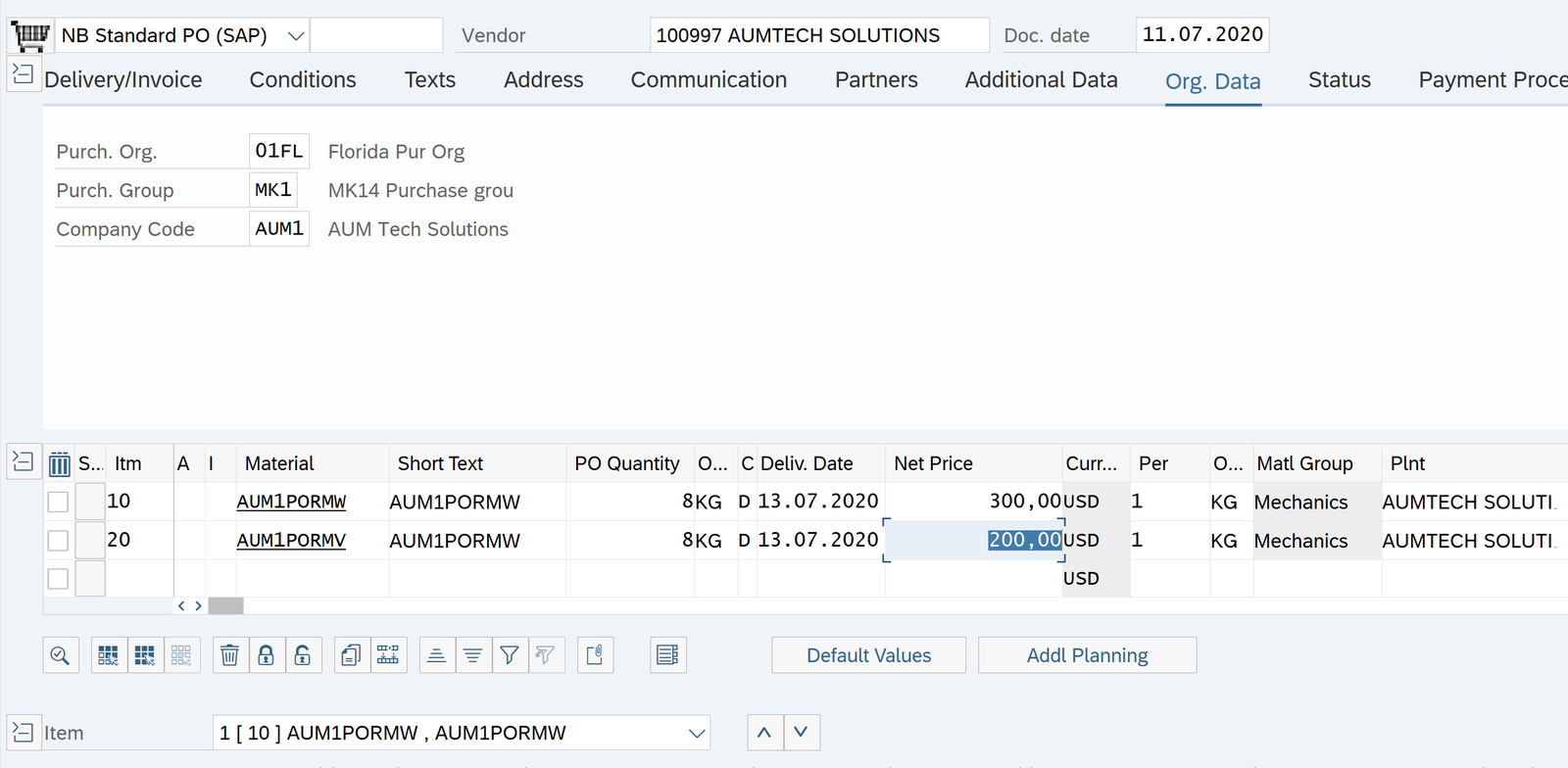

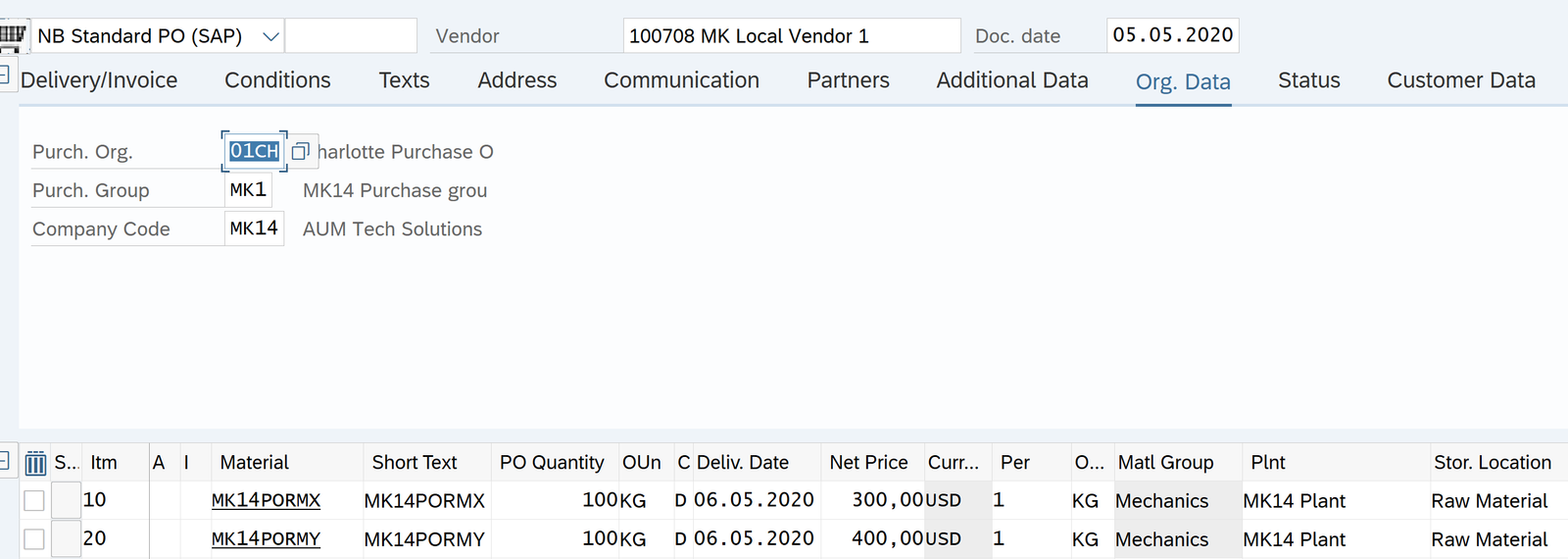

Create Purchase Order for Raw Material: ME21N

Standard PO (SAP) created under the number 4500043447

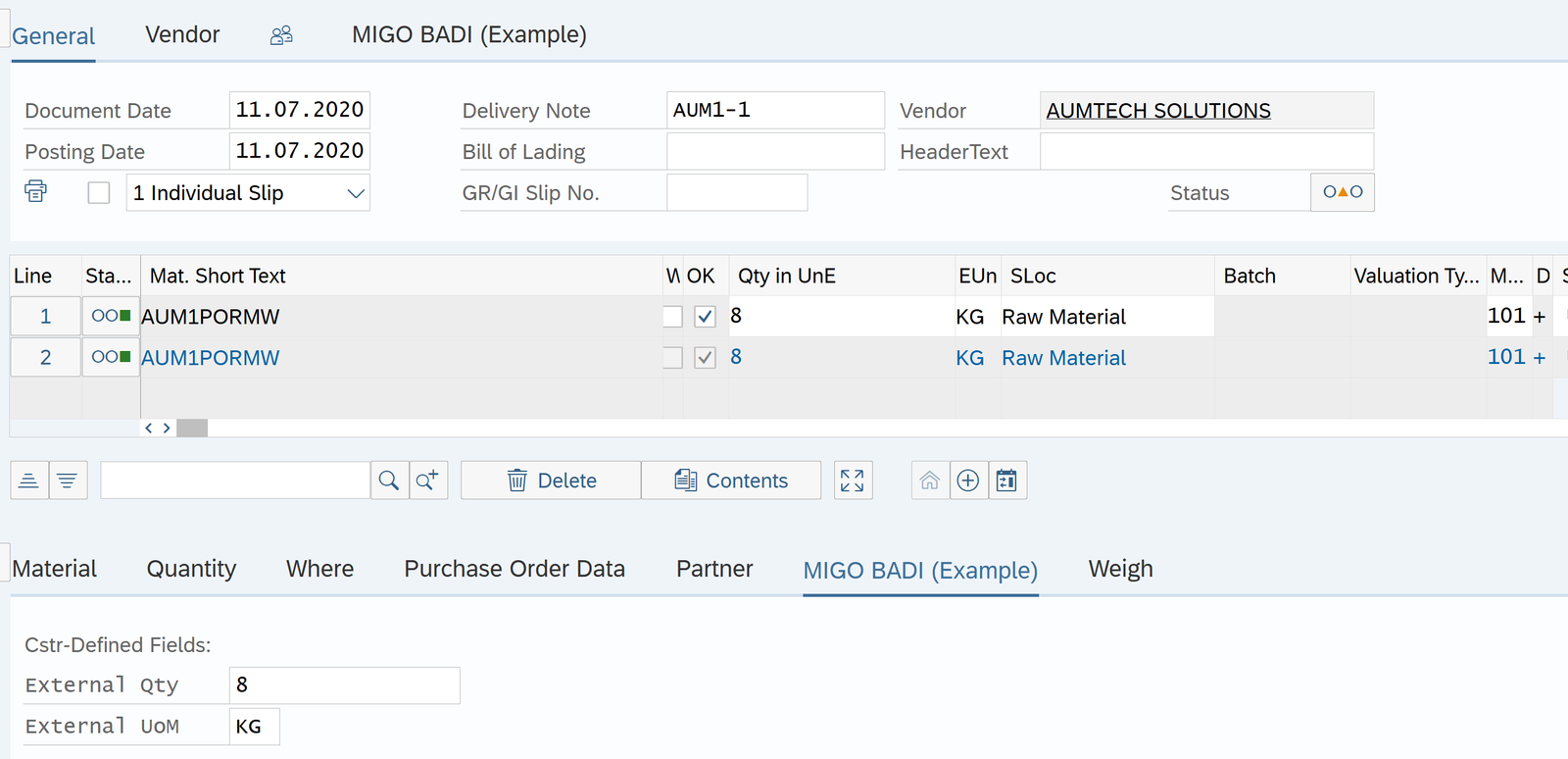

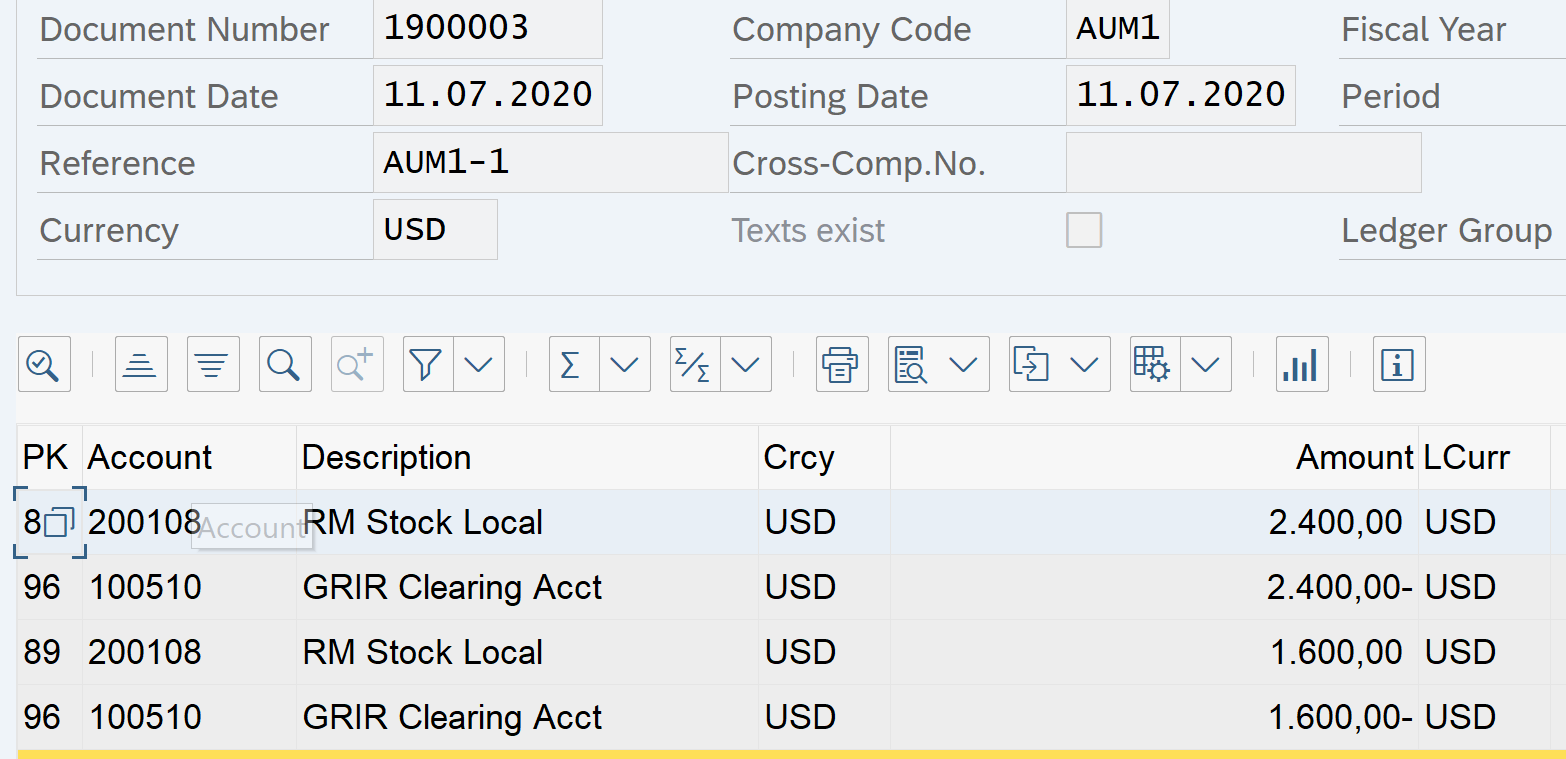

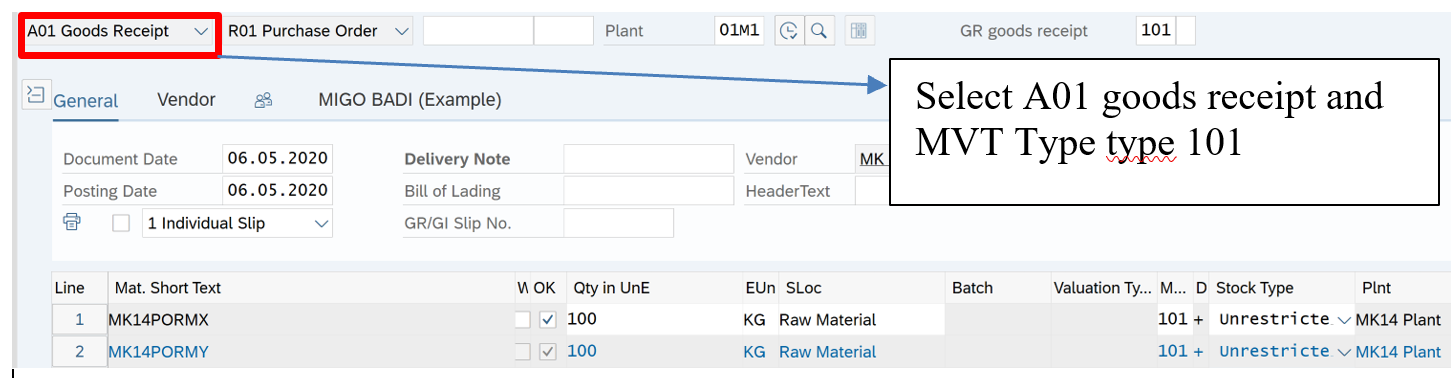

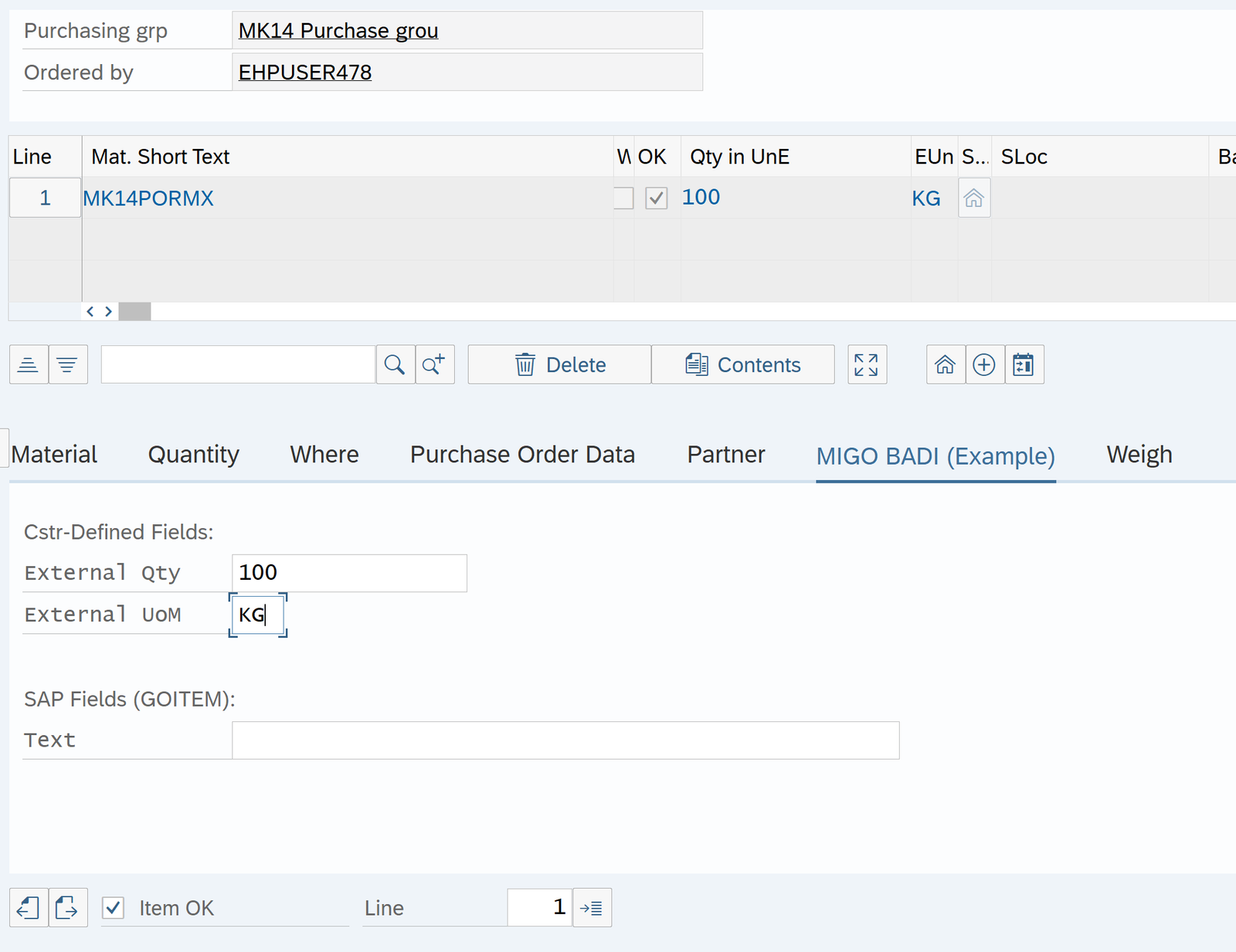

Raw Material Receipt from Vendor: MIGO

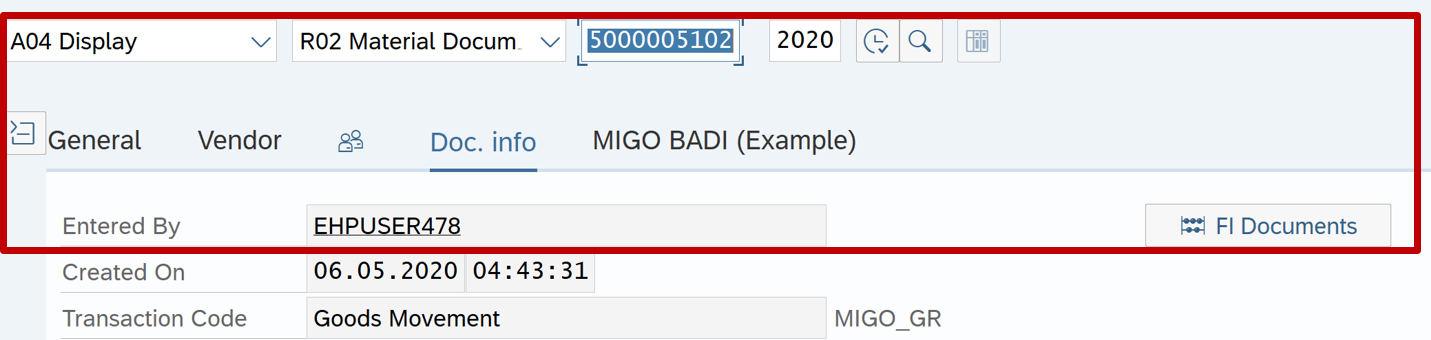

MIGO – Display

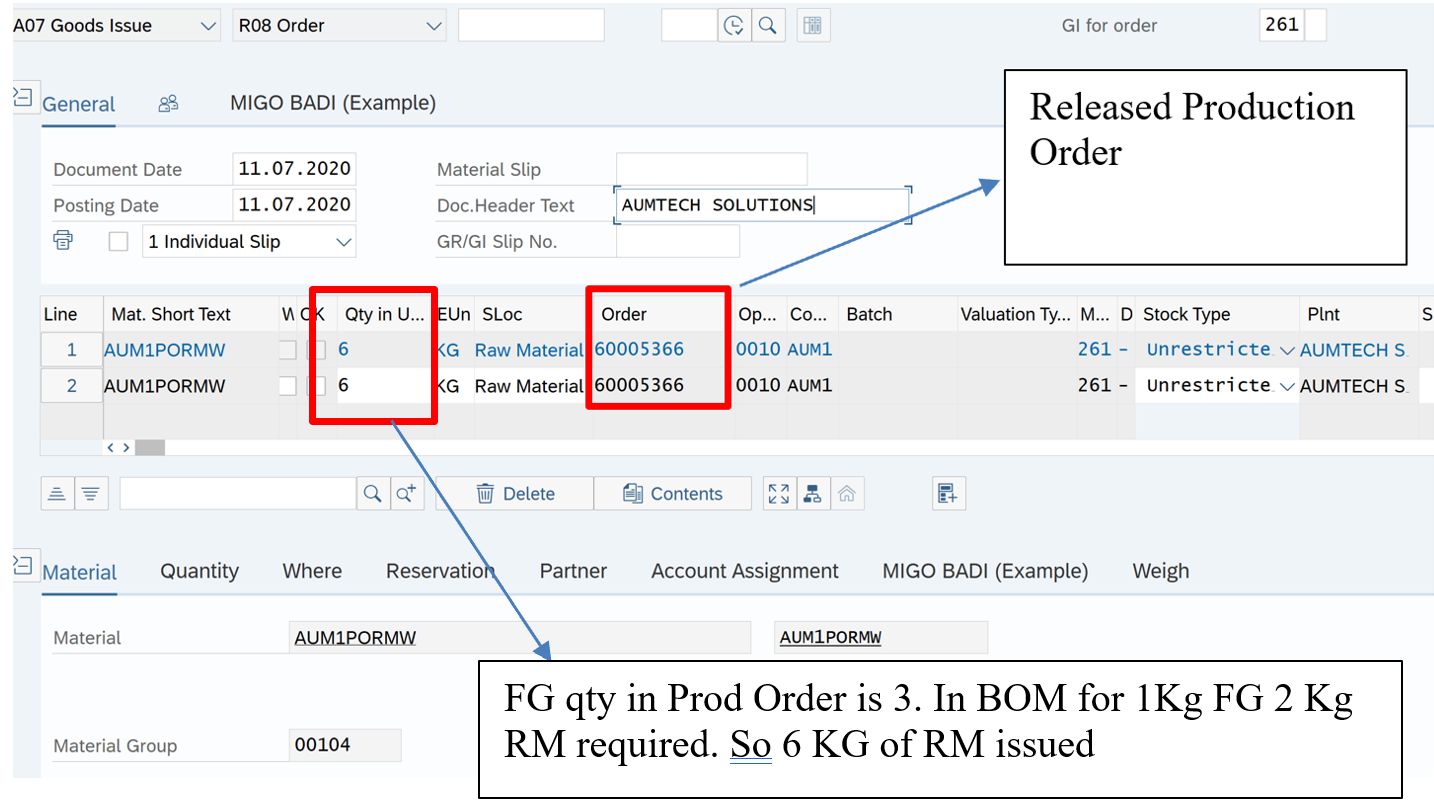

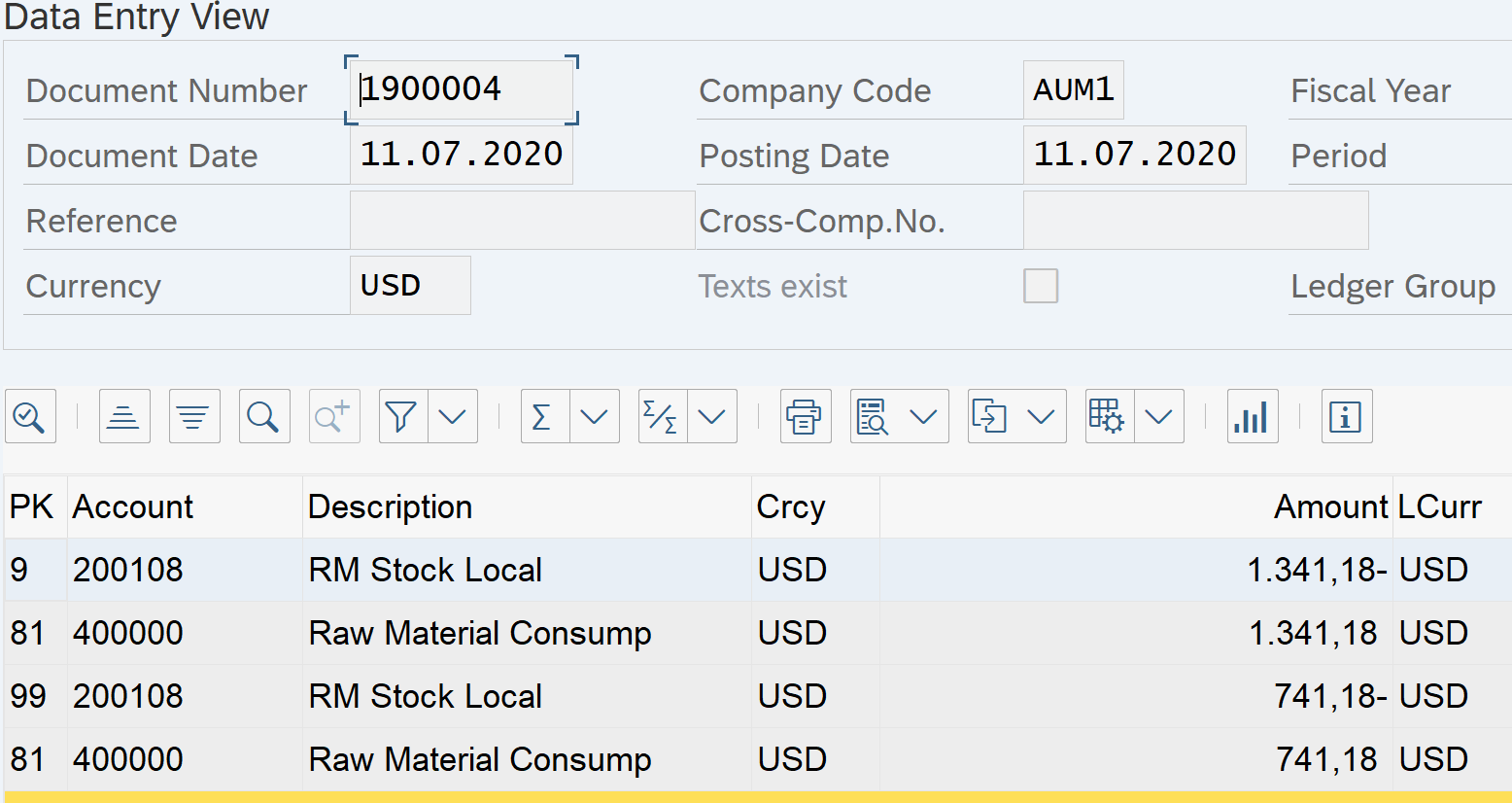

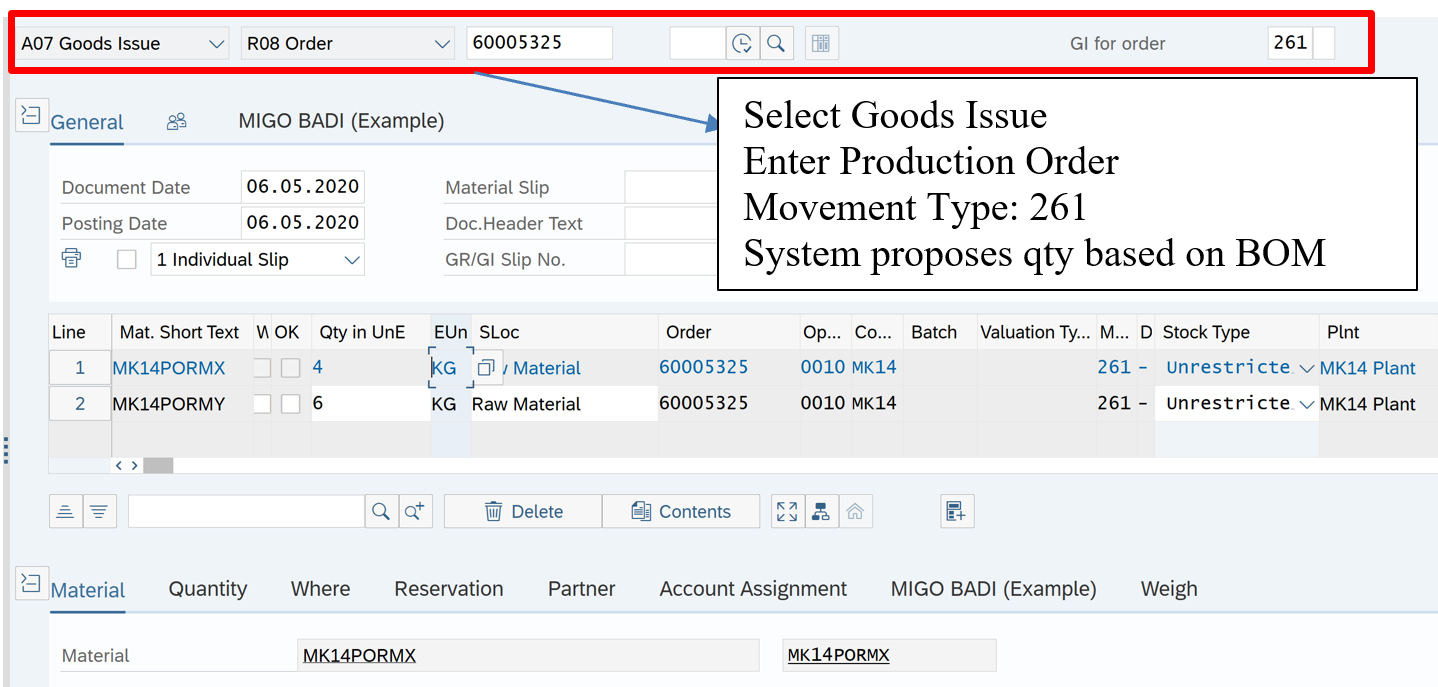

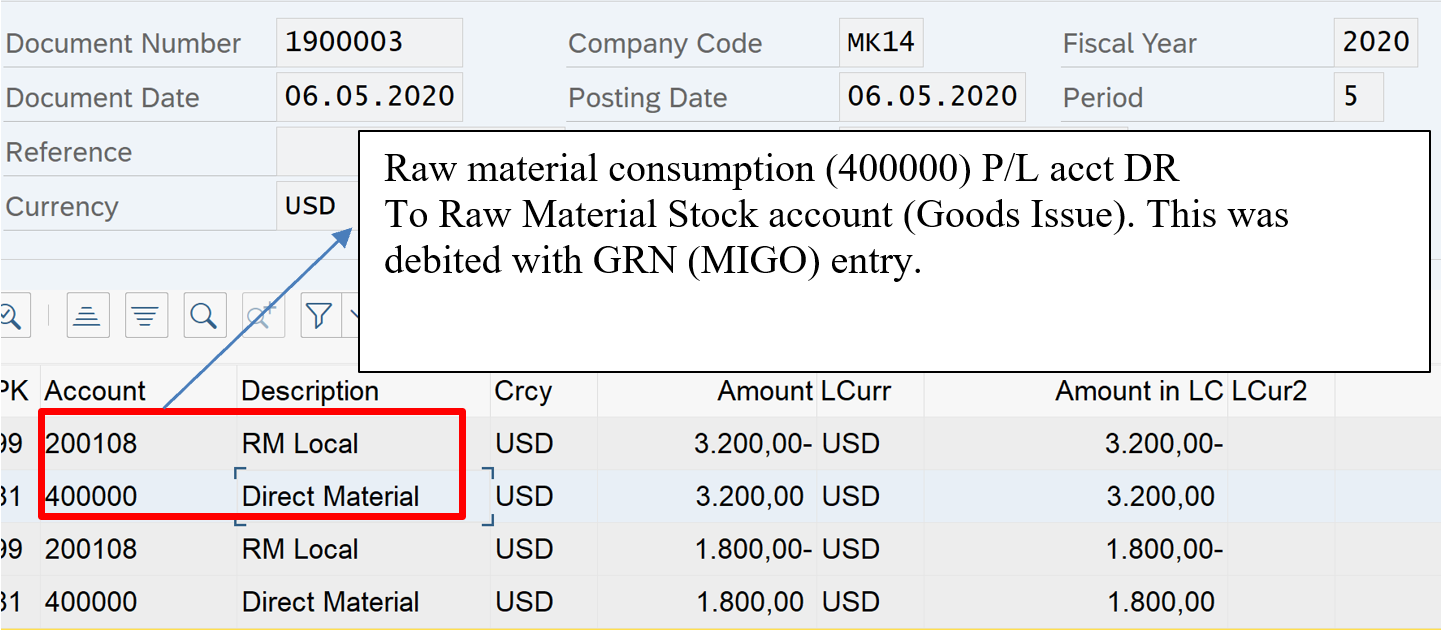

Issue Raw Material to Production Order: MIGO

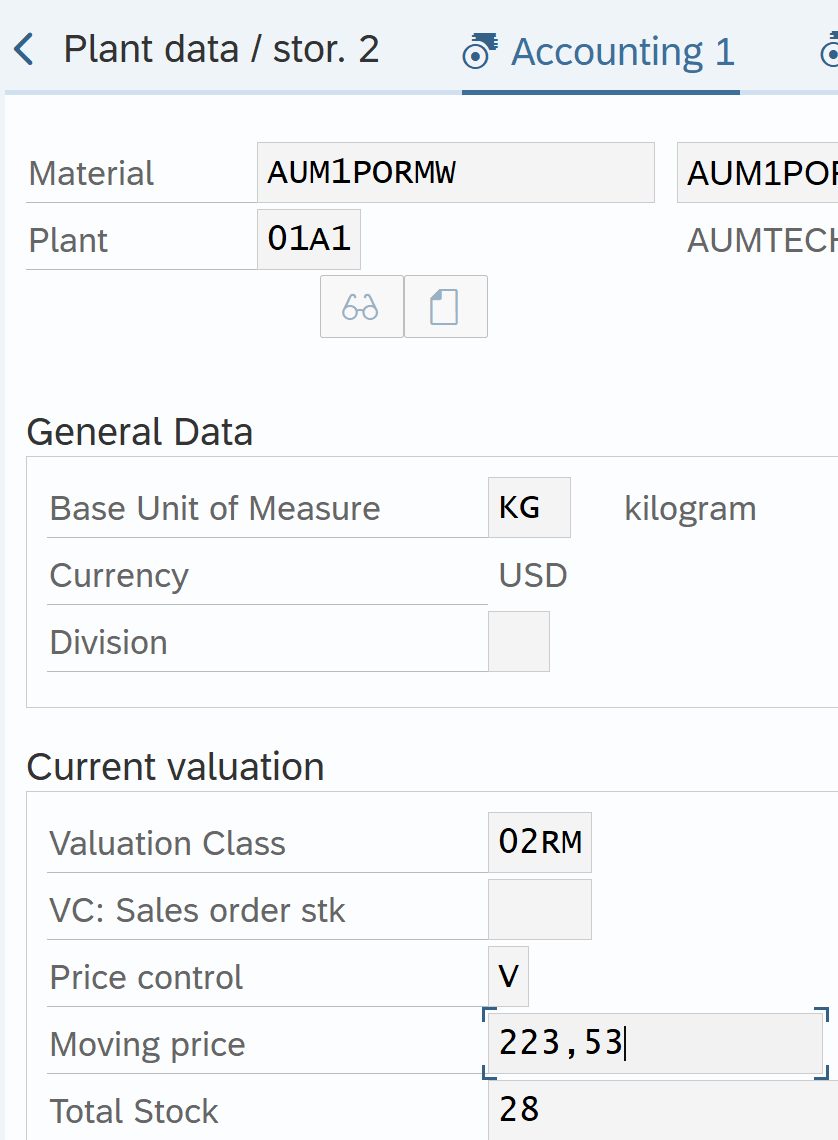

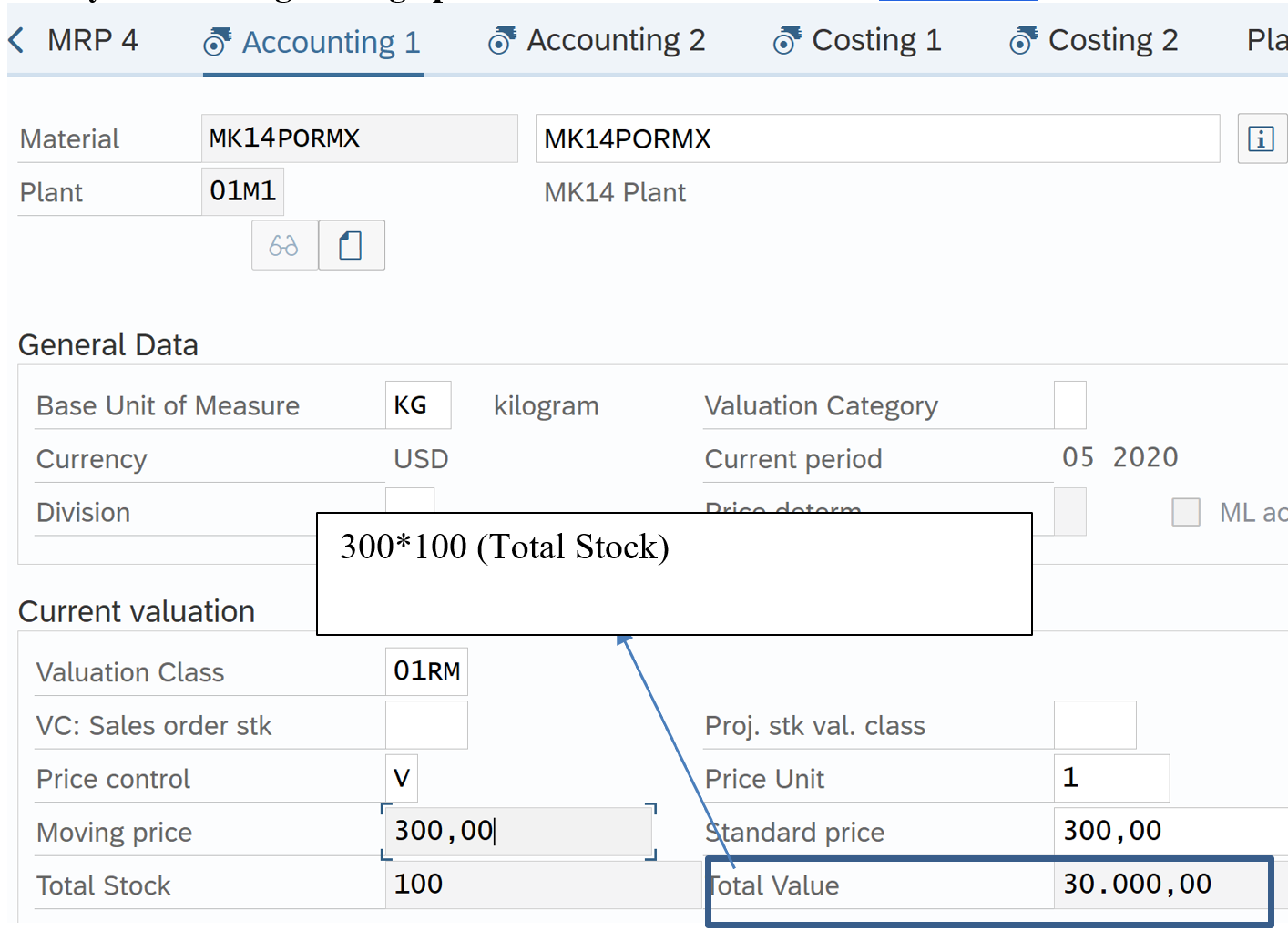

Raw Material Issued to Production at Moving average price. Check in MM03

Moving average Price MM03

Go to Operations and confirm actual hours spent on converting Raw Material to FG: CO11N

- Display Standard cost estimate: CK13N

- We have calculated Standard cost / Estimated cost of the finished product. Now we will manufacture finished good and calculate its actual cost. Then find variances between standard cost and actual cost

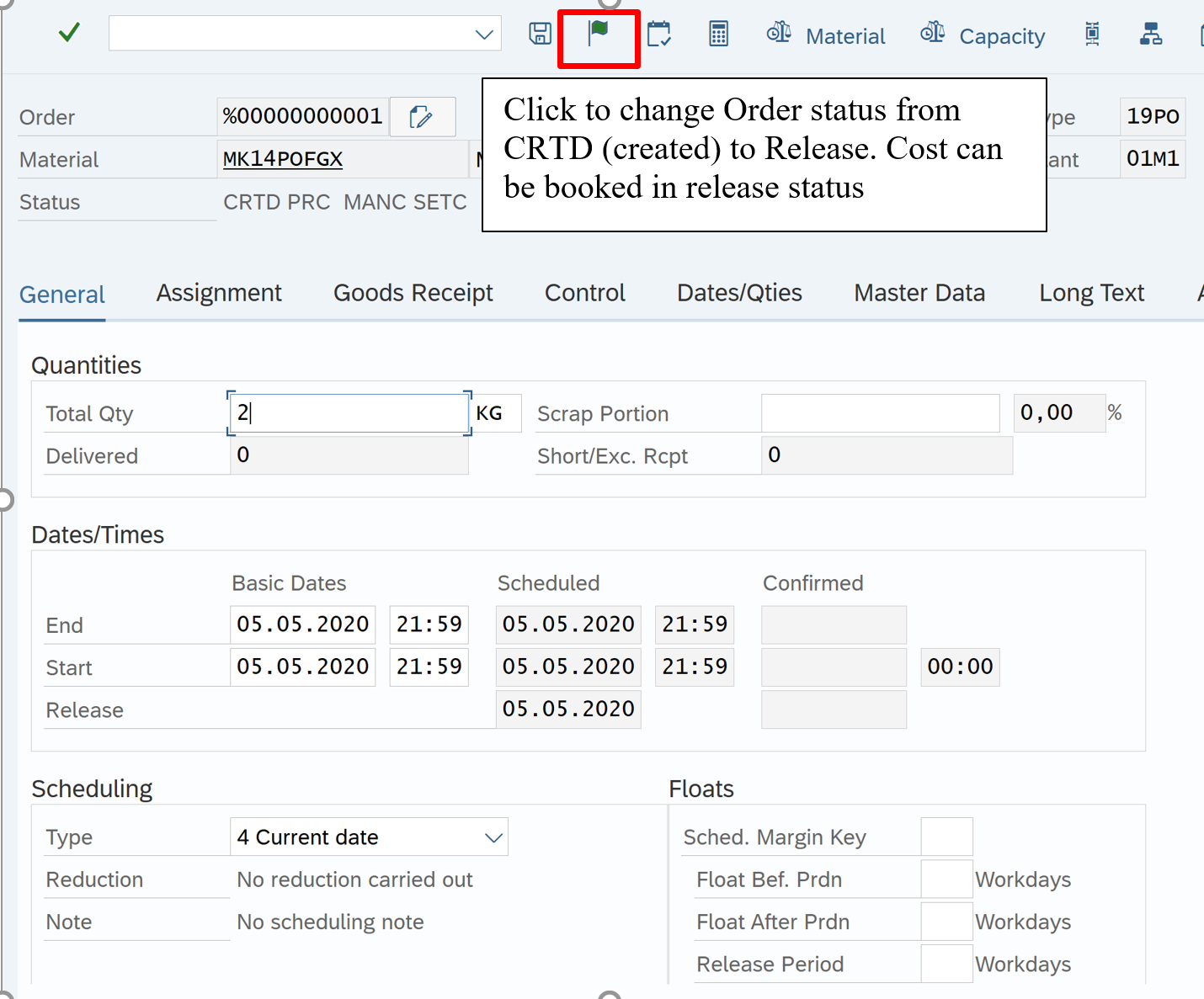

Steps to manufacture finished goods, find actual cost and month end product costing activities

- Create Production Order to manufacture FG: CO01

- When Production is saved Planned cost of FG is calculated in the production order. Now standard cost is always for 1 kg of material. Planned cost is for the total Production order material which can be 2 kg or more. There is difference between Standard cost and Planned cost due to fixed cost being same in both

- Create Purchase Order for the Raw Material: ME21N

- Raw Material Receipt from vendor: MIGO

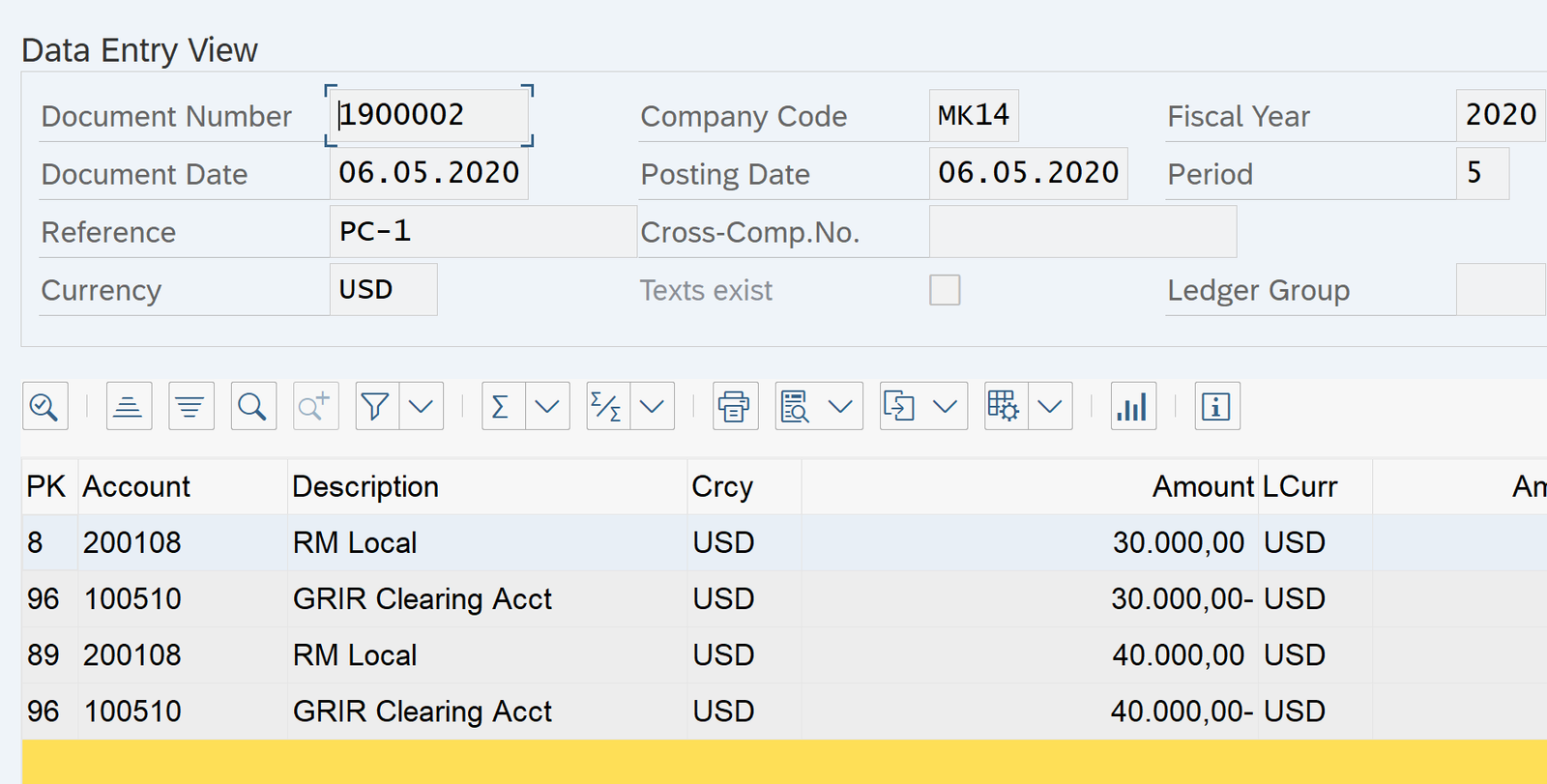

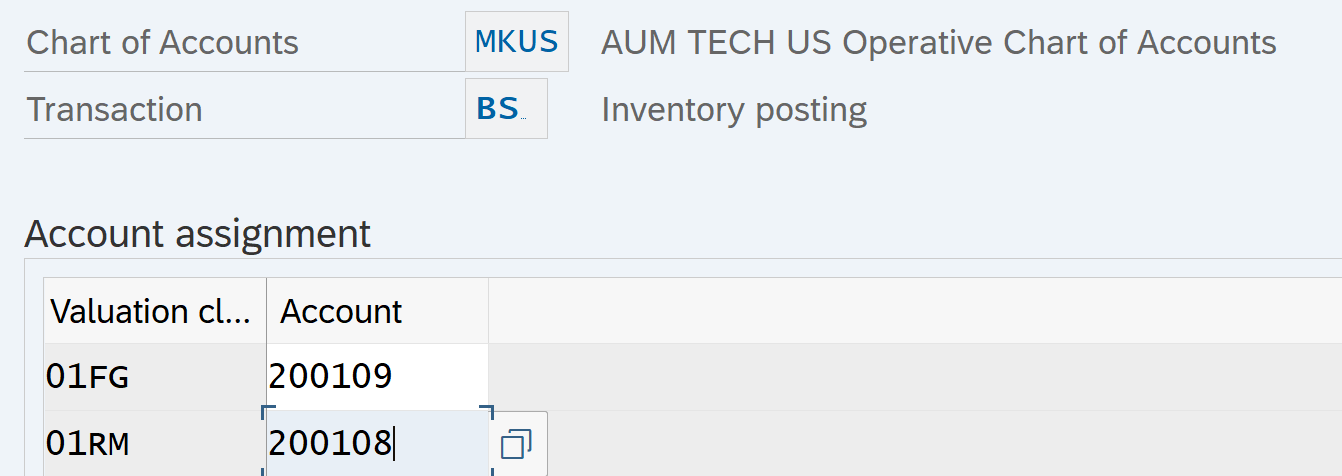

- Inventory GRN Posting: OBYC-BSX: 200108 (RM) DR to GRIR 100510 CR

- Issue Raw Material to Production Order: MIGO

- Go to Operations / Work Enter. Enter and confirm the actual hours spent production FG in each work center: CO11N

- Display Production Order: CO03 – Go to Cost Analysis – Actual cost will now be updated with actual operations hours

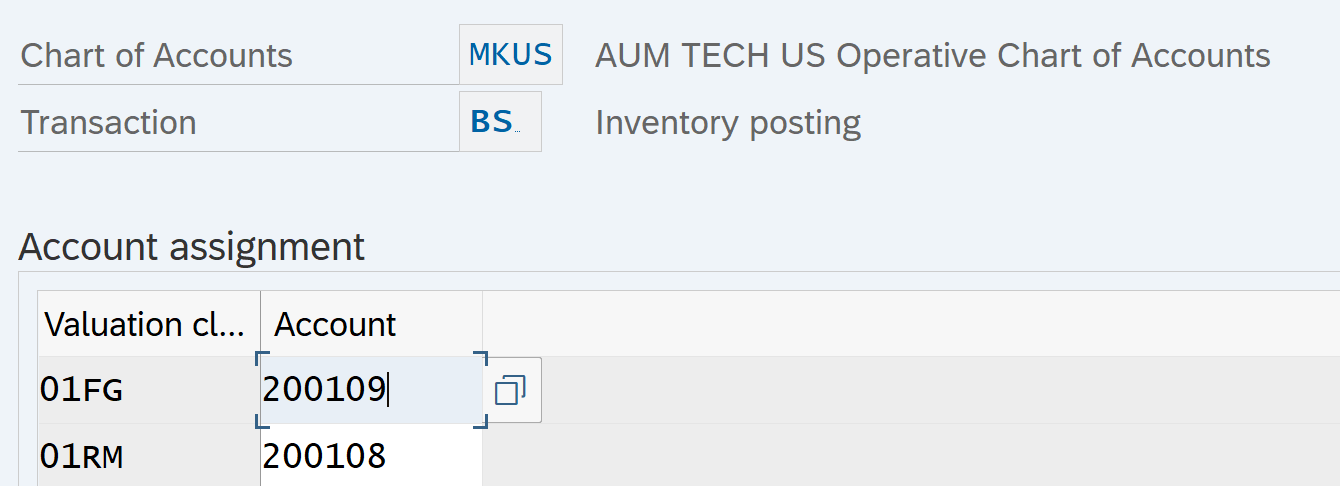

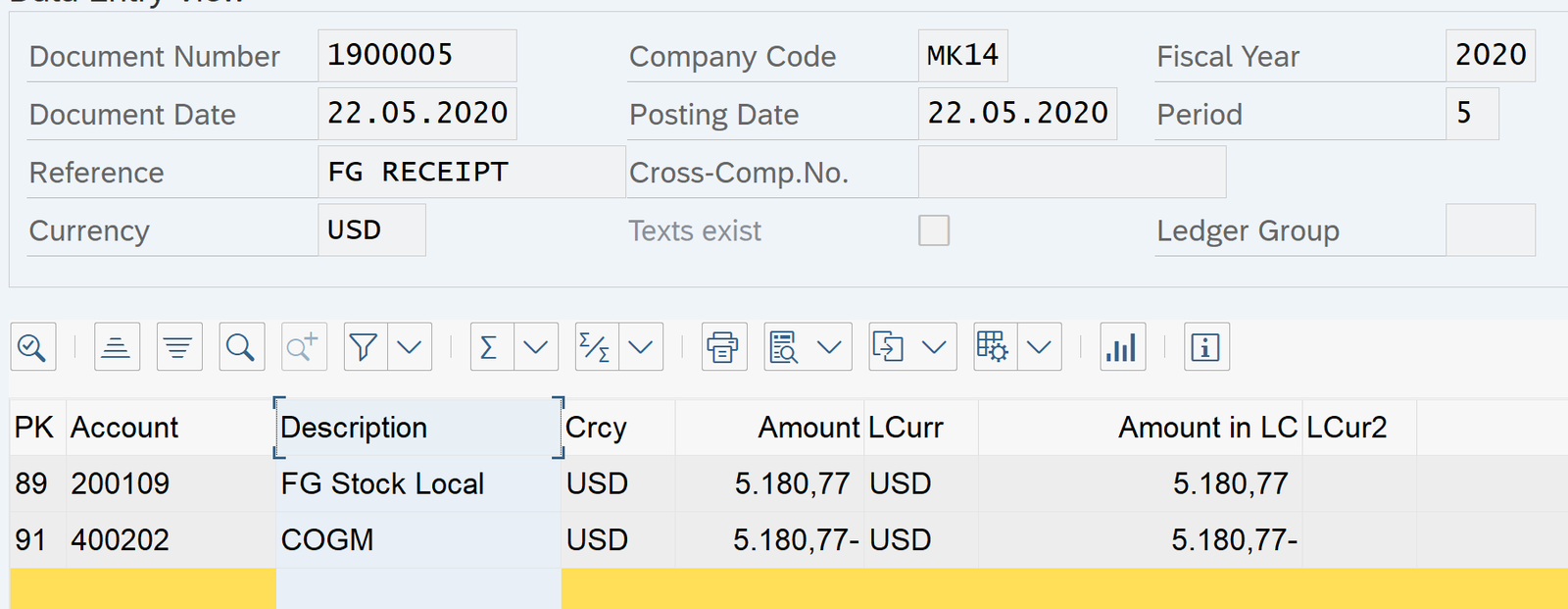

- As the Raw Material is converted to Finished goods in the Production Order. Issue Finished goods to inventory from Production Order: MIGO

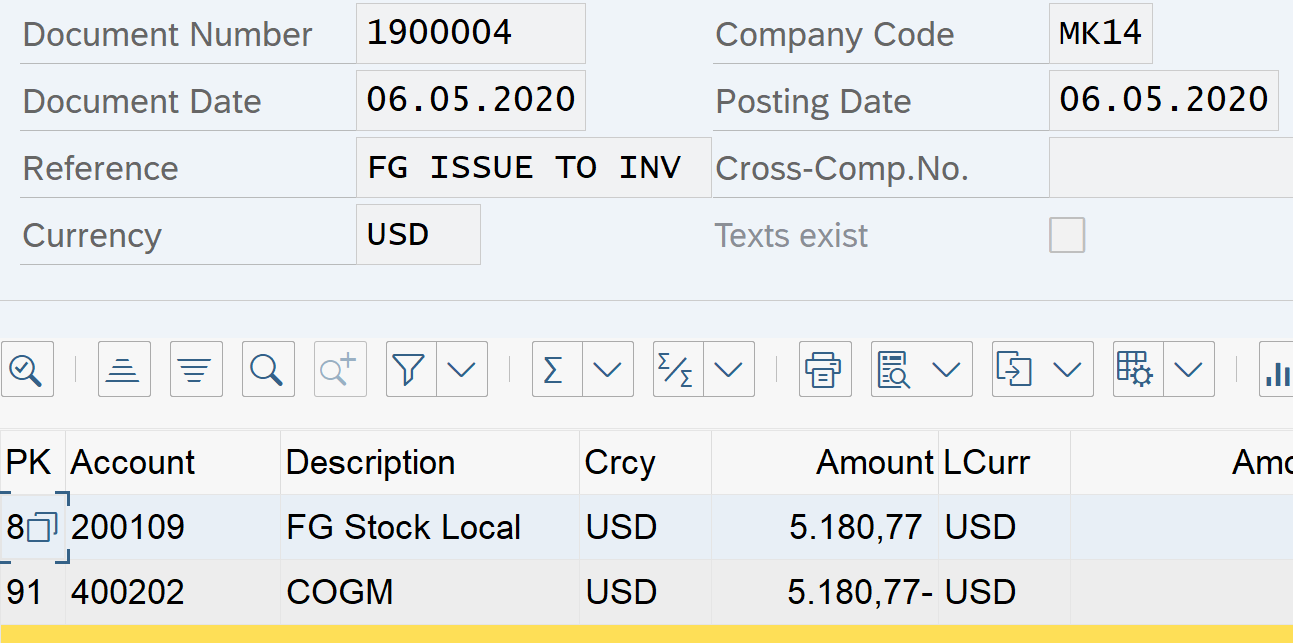

- Accounting Entry:

- OBYC- BSX: FG Stock (200109) DR

- OBYC – GBB- (Gen Modi: AUF, Valuation Class: 01FG) : 400202 CR

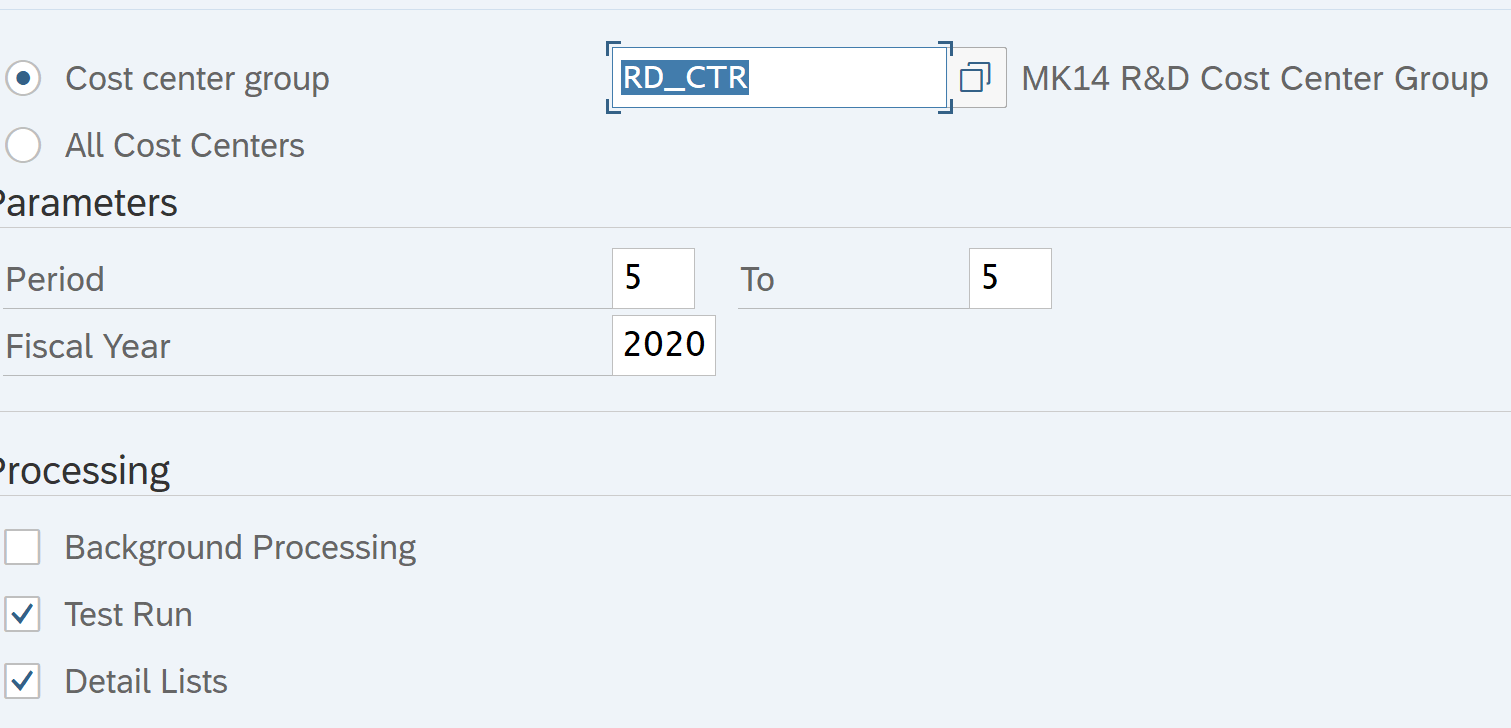

- Calculate Actual Activity Price:

- Manually: KBK6

- OKES, OKEW, KSS2, KSII

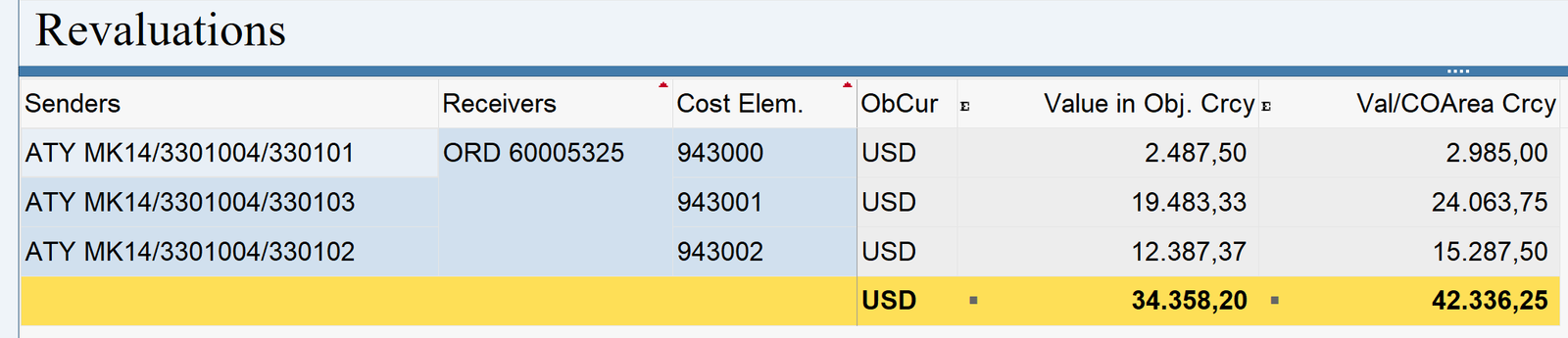

- Revaluate Operations activities at actual price: MFN1

- Calculate actual OH: KGI2

- Verify the actual OH cost in Production Order: CO03

- Perform Month End cut off / period change for WIP: KKA0

- Perform WIP Calculation: KKAX

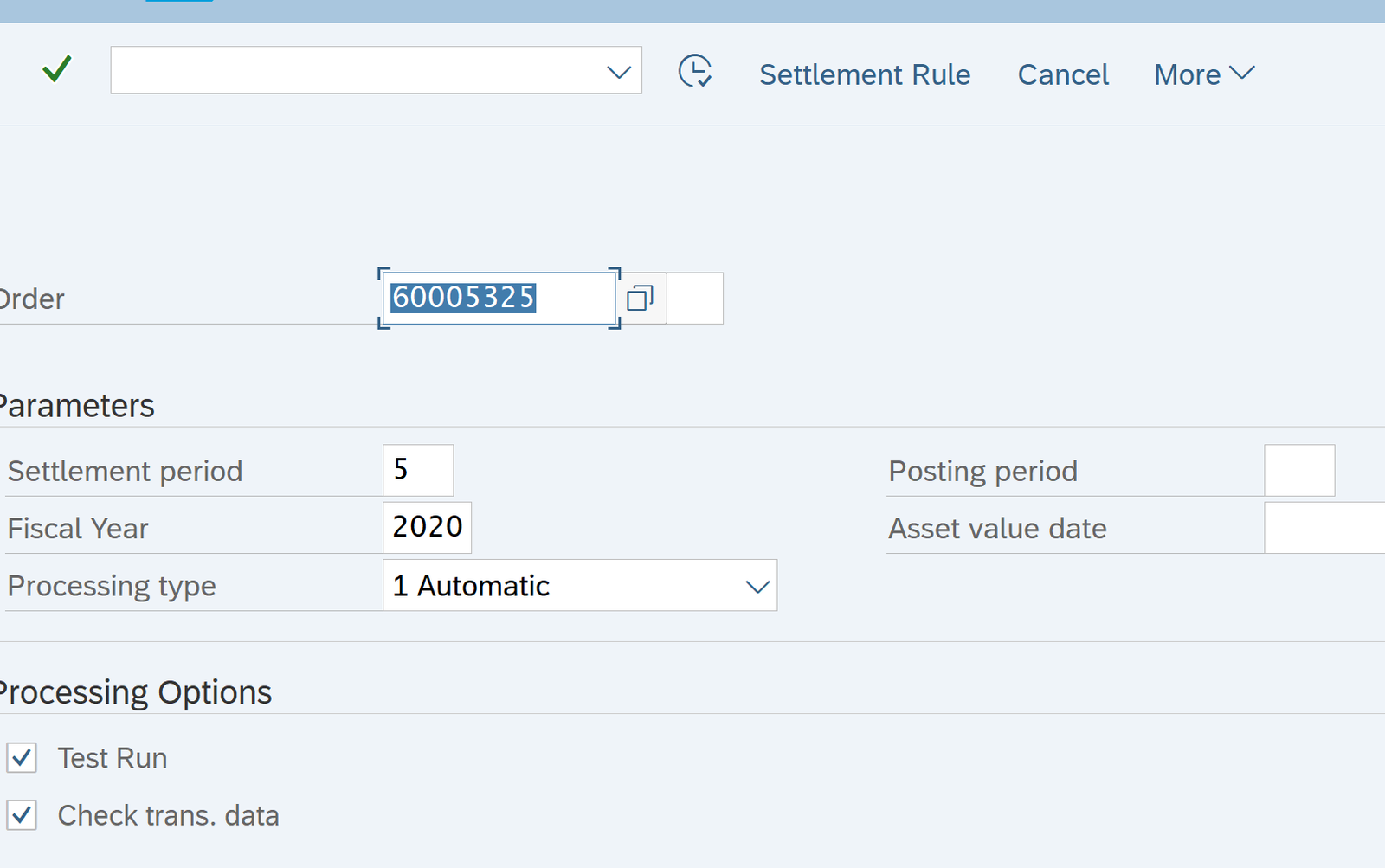

- Before Variance Calculation Production order should be settle. Settle Production Order: KO88

- Calculate Variance: KKS2

- Define Goods received valuation for order delivery

Path: SPRO – Controlling – Product Cost Controlling – Cost Object Controlling – Product Cost by Order – Define GR value for Order Delivery

- Account Assignment in OBYC

Tcode: OBYC

GL Account

400202- COGM

400203- COGS

400000 – Raw Material

Accounting entry when goods received from production order

Stock Acct DR

To COGM Account

- Create Production Order

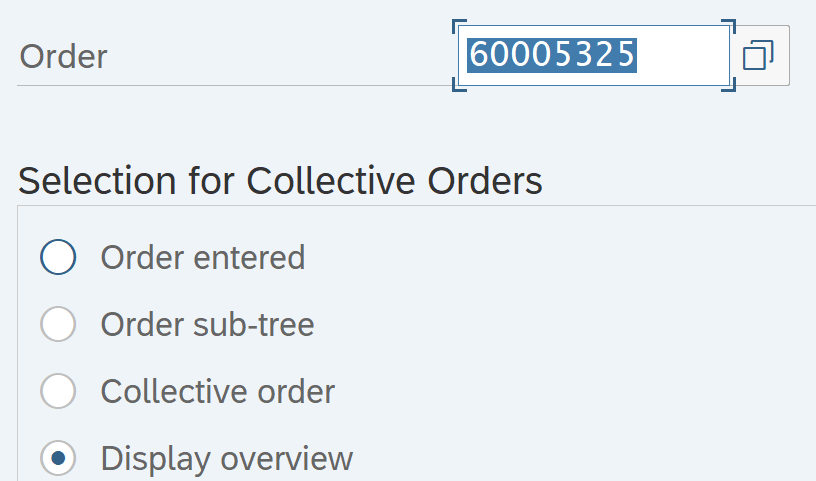

Transaction Code: CO01

Standard cost is always for 1 Kg

Planned cost is for production 0rder quantity. There is difference in these two cost due to fixed cost like setup cost which is same for 1 kg and 2 kg

Click on cost order to determine the Planned cost of production order

Click GOTO – Cost – Itemization to view planned cost

Click Save

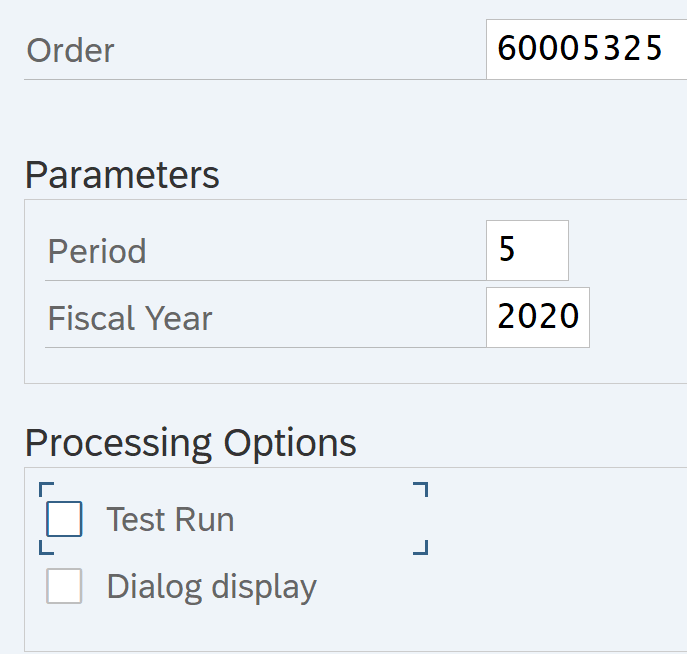

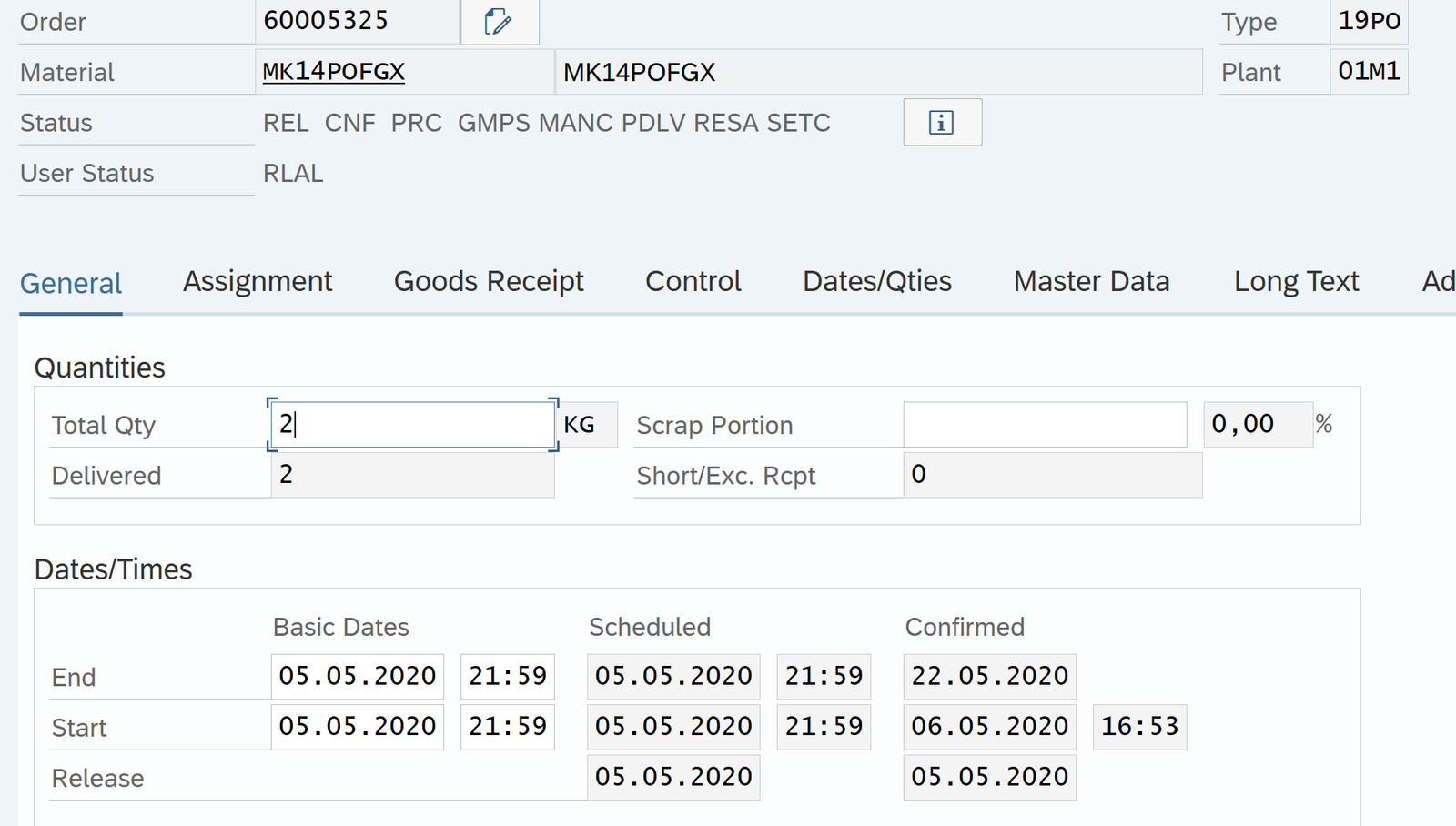

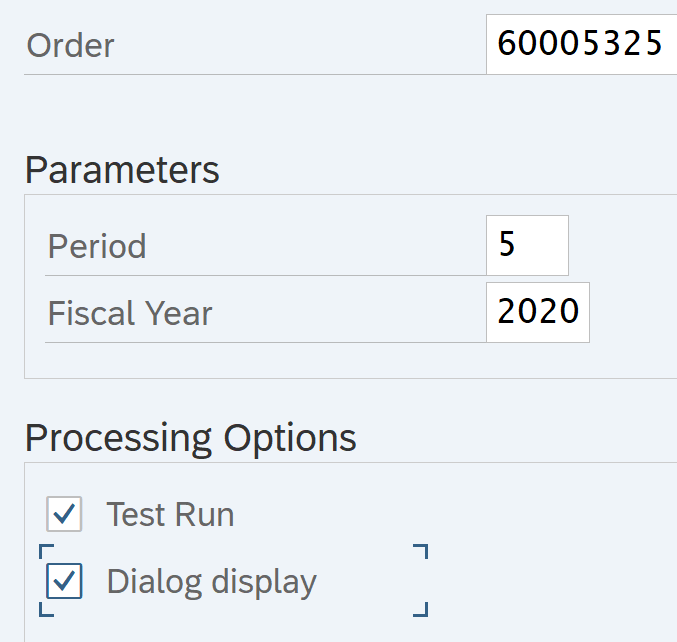

Production Order number 60005325 saved

Tcode: ME21N

Standard PO (SAP) created under the number 4500042902

Release Purchase Order: ME28

- Post Raw Material Goods Receipt

Tcode : MIGO

Material document 5000005102 posted

Display GRN material document: MIGO

Inventory / GRN posting Config : OBYC – BSX

Verify the Moving average price of Raw material MK14PORMX : MM02

- Raw Material Issued to Production

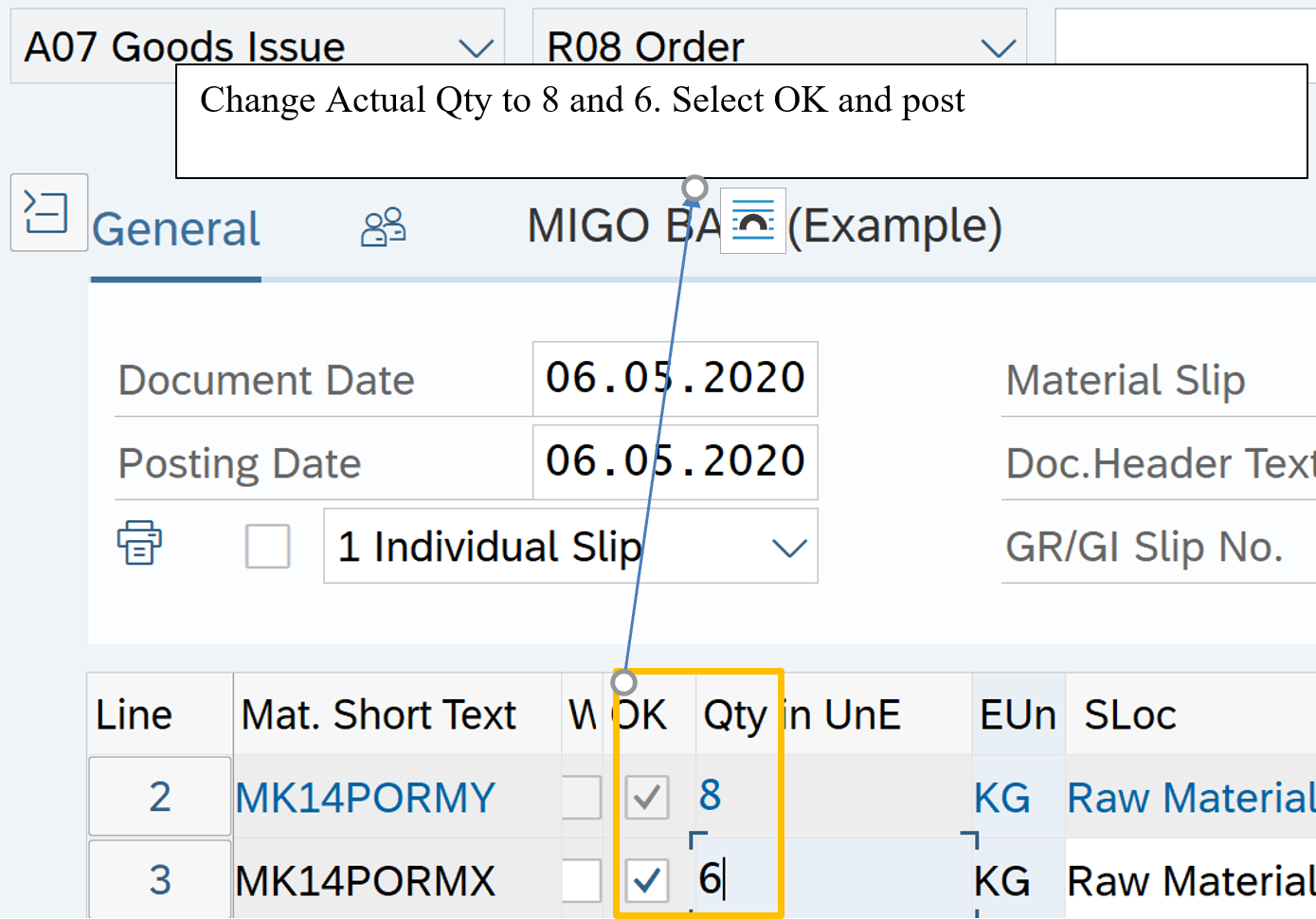

Tcode: MIGO

Material document 4900008071 posted

Verify the actual raw material cost updated in production order 60005325: CO03

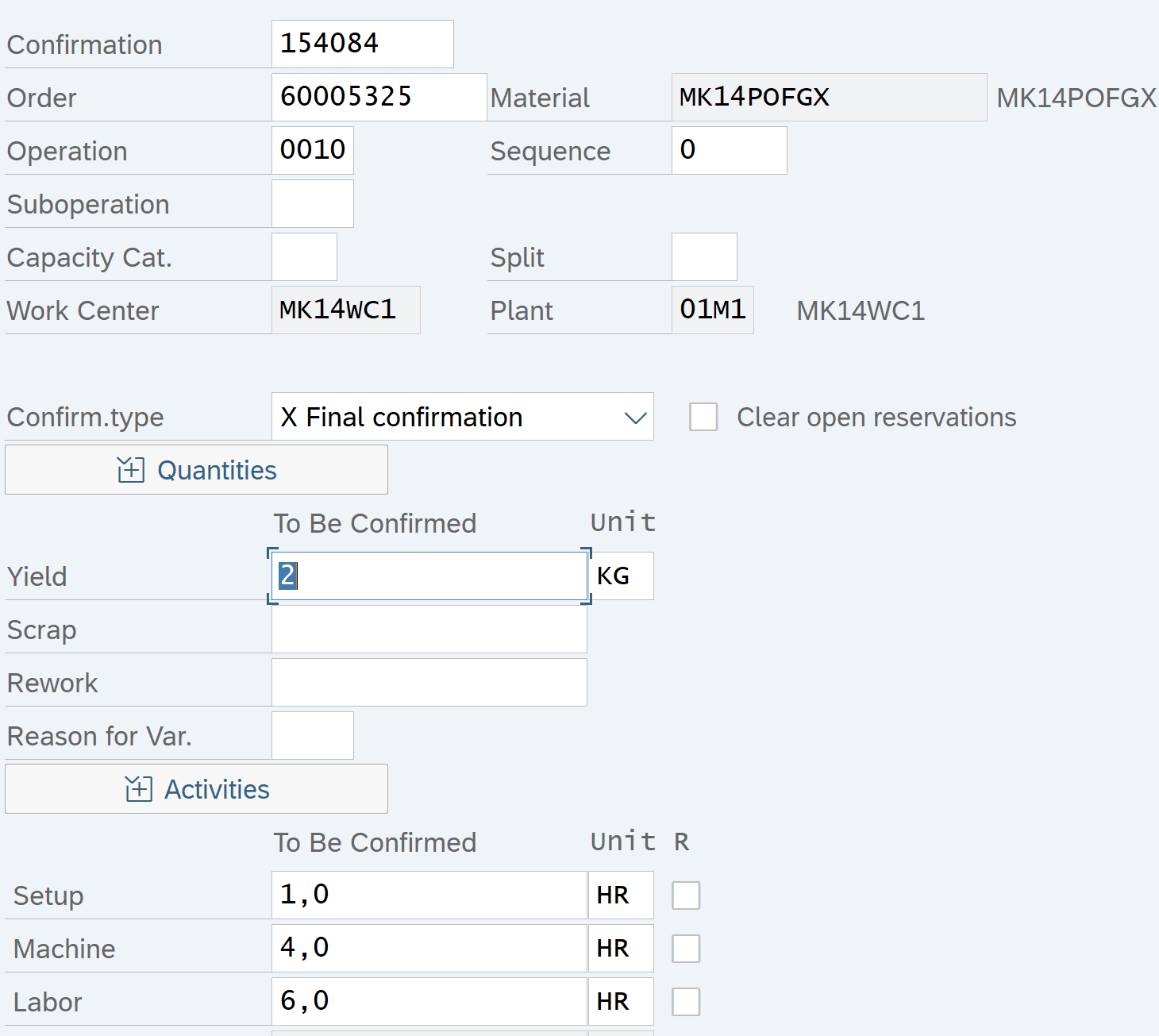

- Confirmation of Activities for Operation

- Assign CO Business Transaction RKL

- Confirmation of Activities for Operation

Tcode: KANK

Assign to secondary postings number range group

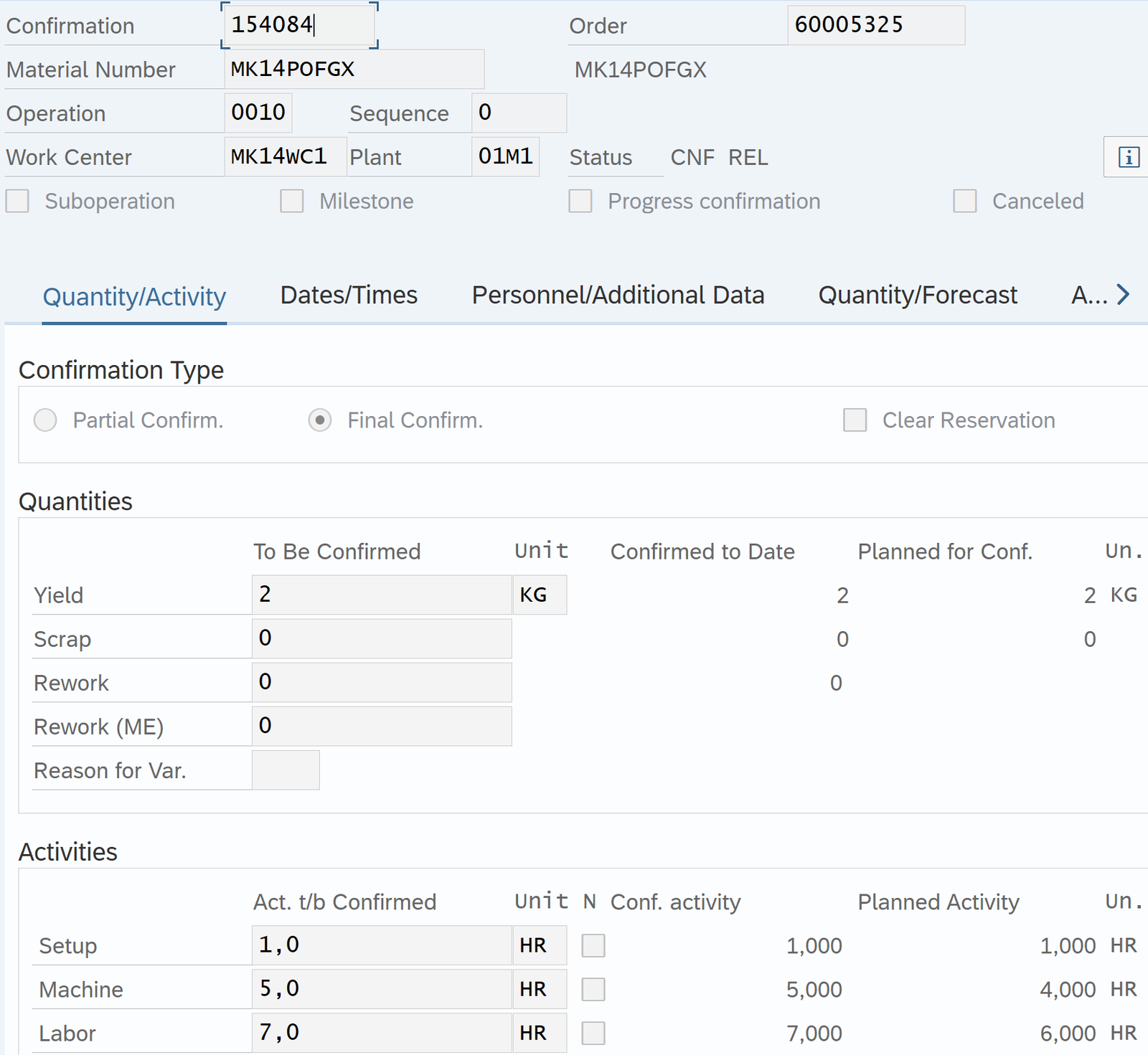

- Confirmation of activities for Operation 10

Tcode: CO11N

Enter Production Order and Operation 10 for actual activity hours hrs. updated

Change M/C and Labor activity to 5 and 7. Actual hrs. differ from Plan

Confirmation of order 60005325 saved- Actual activity hours confirmation

Click on Goto – display to see the activity confirmation for Operation 10

Actual hours for activity

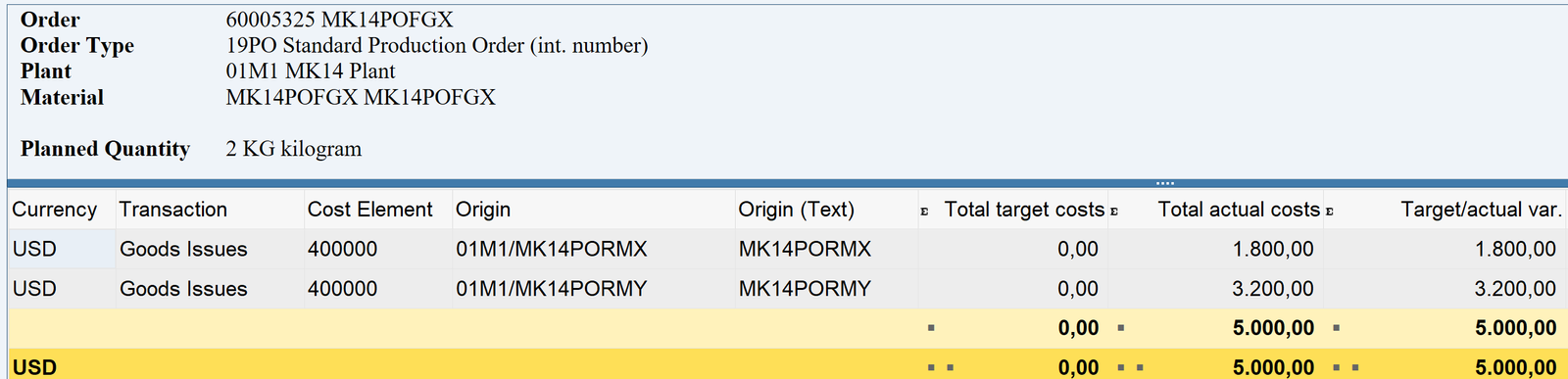

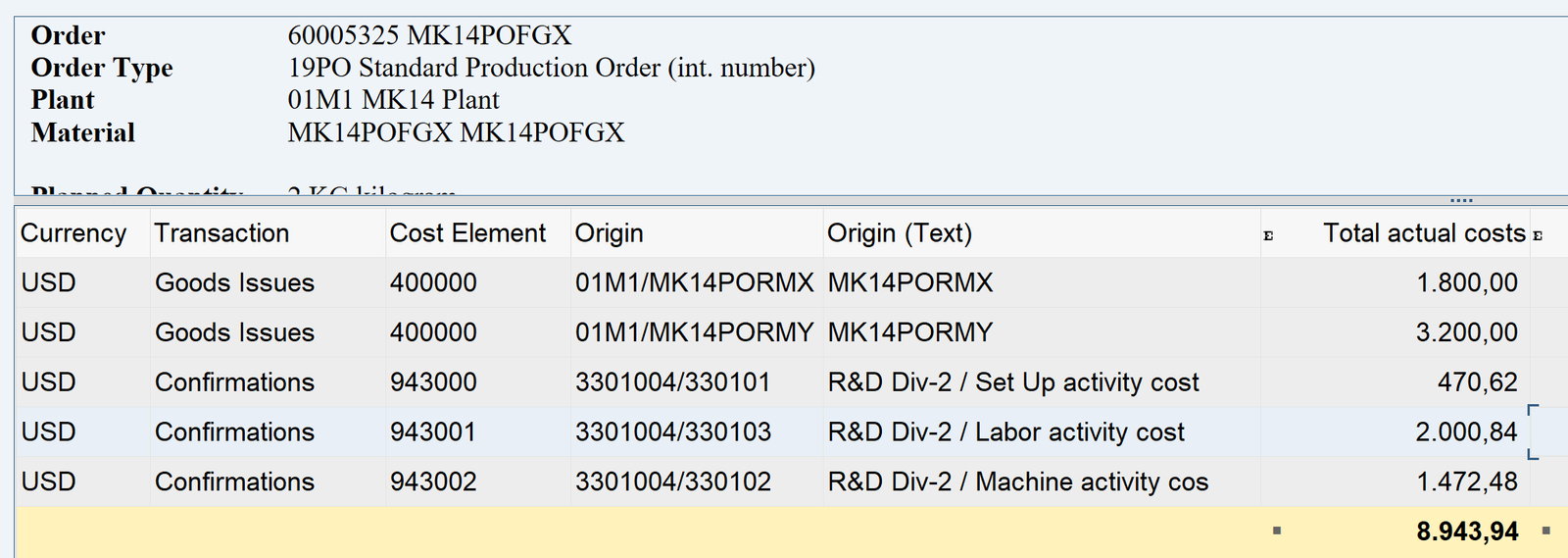

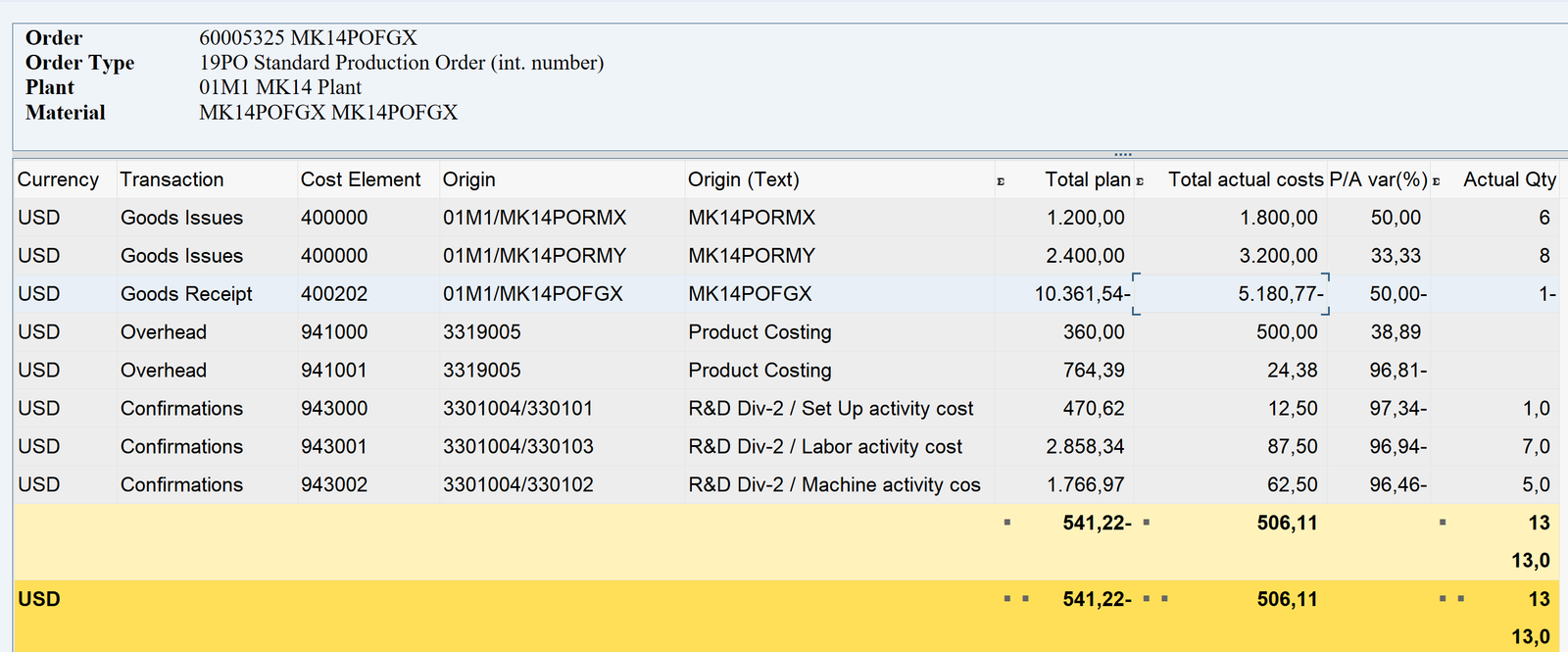

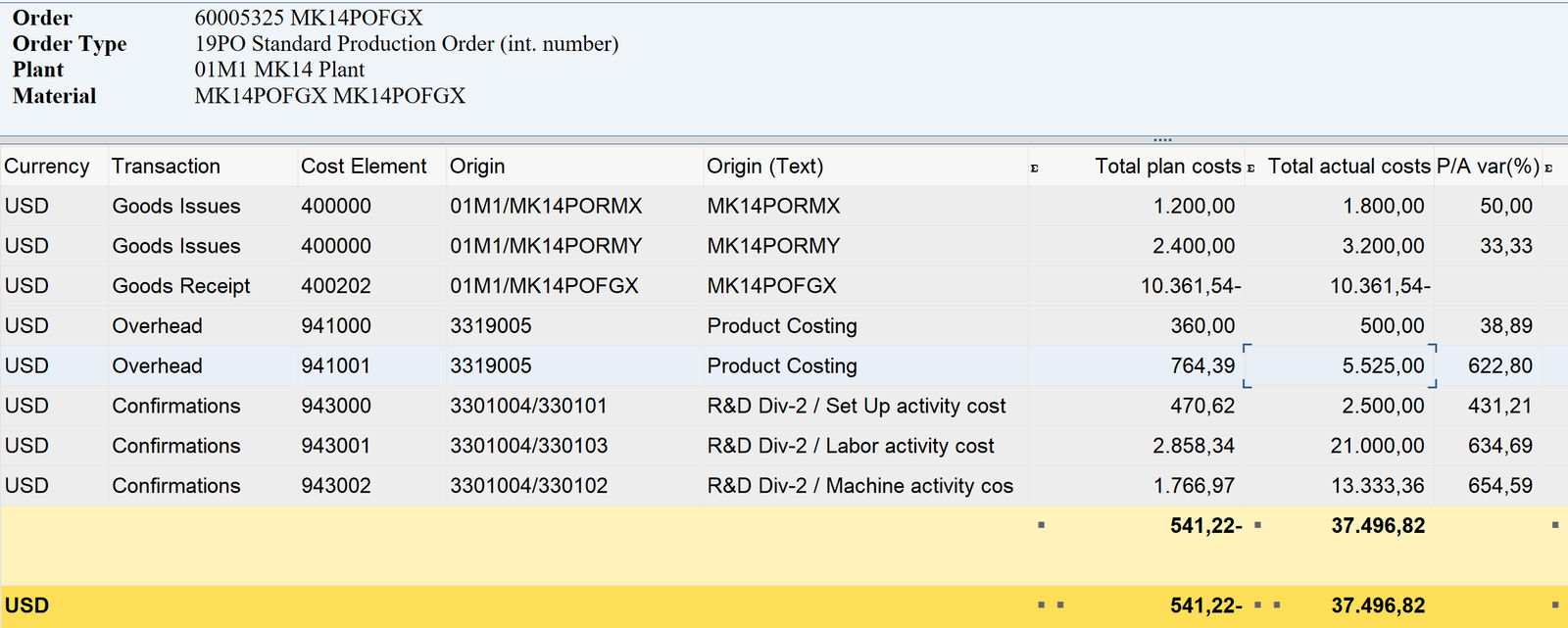

Display Production order: CO03

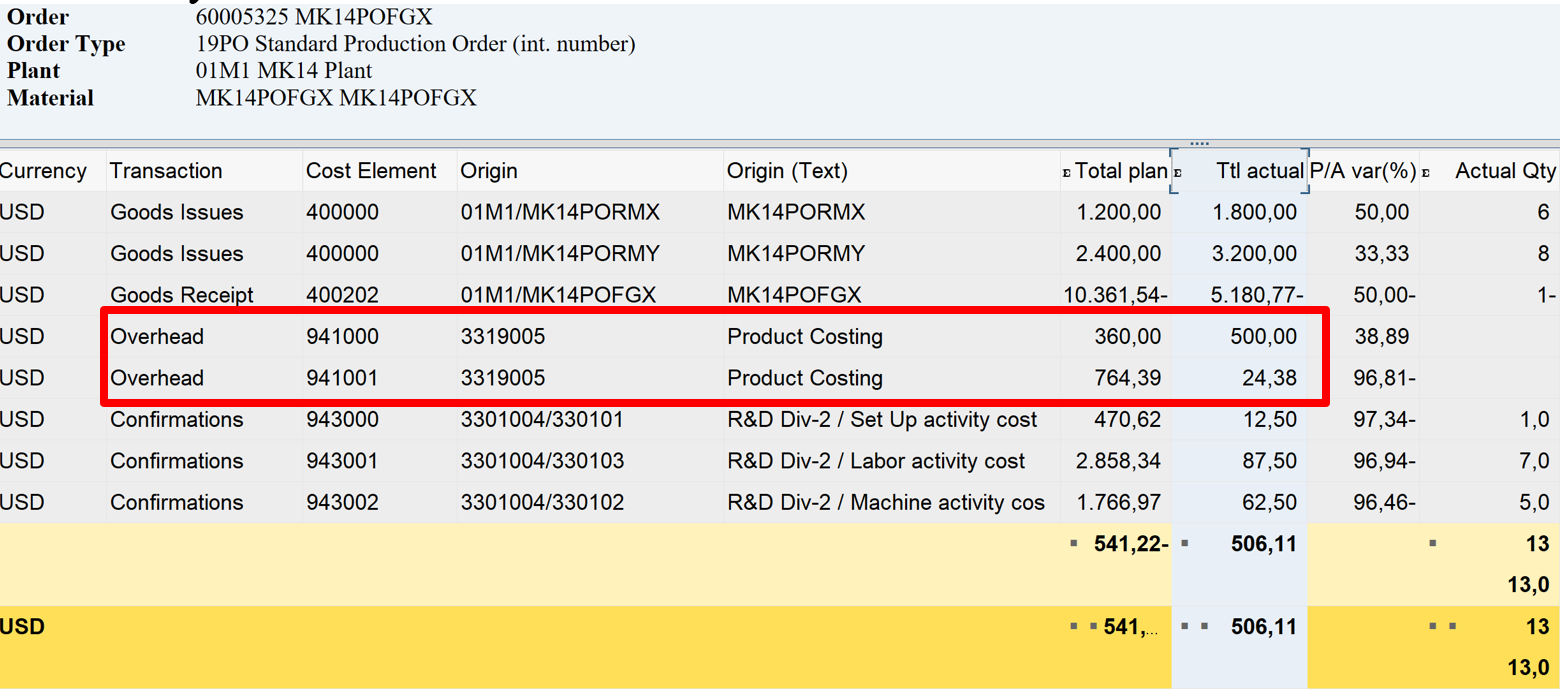

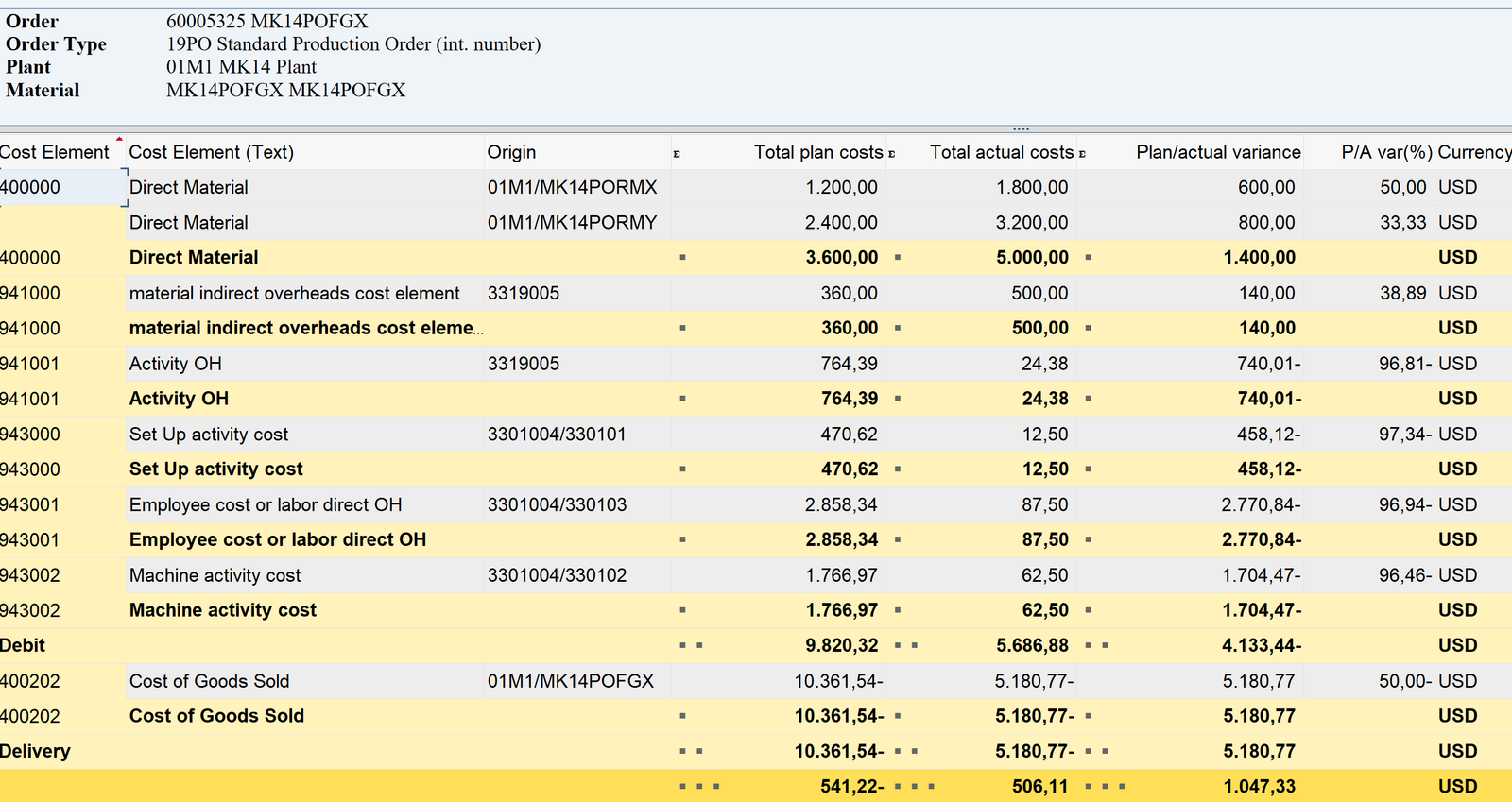

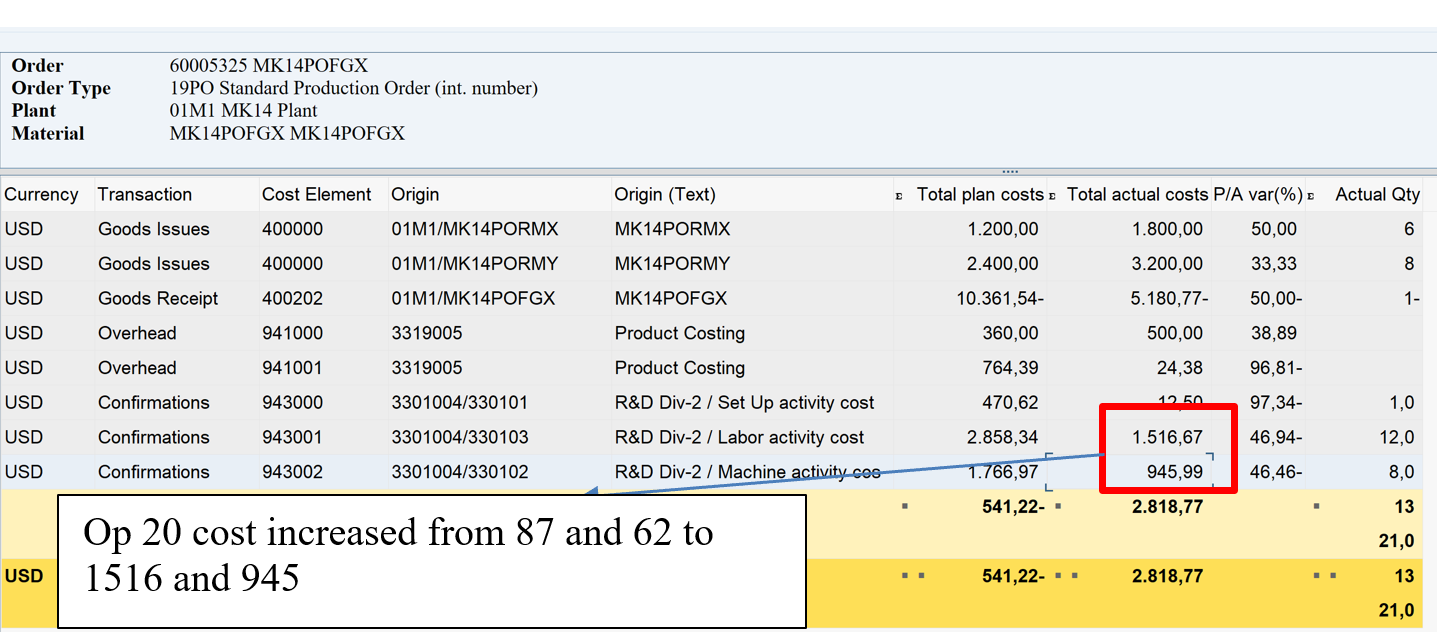

Click GOTO – Cost – Analysis – Actual cost updated with Operation 10

| Actual Cost | |||||||

| Raw Material | Kg | Avg Price | Actual Cost | ||||

| RMX | 6 | 300 | 1800 | ||||

| RMY | 8 | 400 | 3200 | ||||

| Total Price RMX +RMY | 5000 | ||||||

| OP 10 Confirmation | co11n | ||||||

| Op10 Planned Cost | |||||||

| Operation 10 (Price from KSBT) | Plan Act Hrs | Plant Rate | Plan Cost | Actual Activity Hrs | Plant Rate | Actual Cost | |

| Setup | 1 | 470 | 470 | 1 | 470 | 470 | |

| Machine | 4 | 294 | 1176 | 5 | 294 | 1470 | |

| Labor | 6 | 285 | 1710 | 7 | 285 | 1995 | |

| Total Planned cost OP 10 | 3356 | 3935 | |||||

| Total | 8935 | ||||||

Tcode: FS00

GL Account: 200109

Balance sheet account, post automatically

Tcode: OBYC – BSX

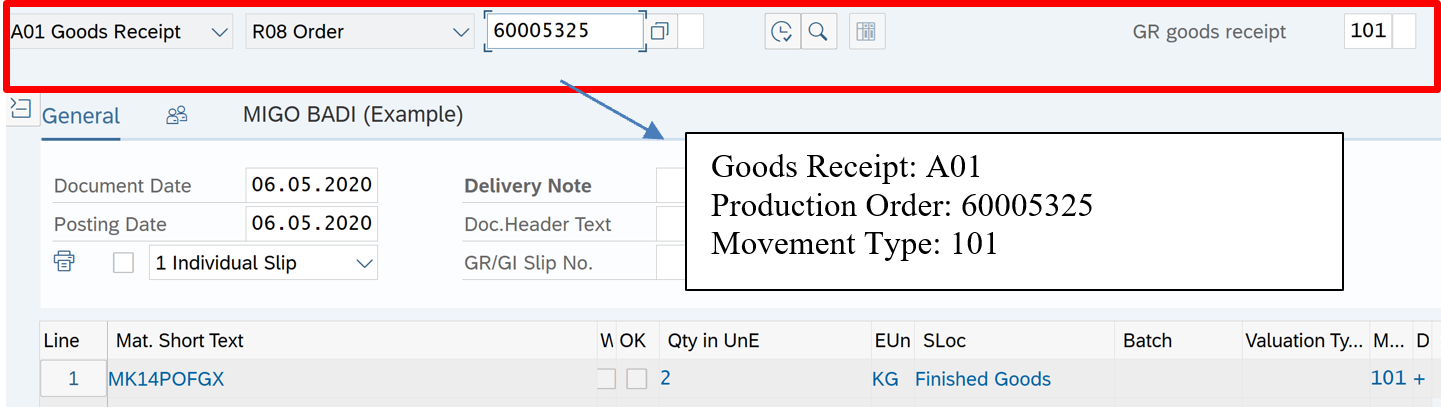

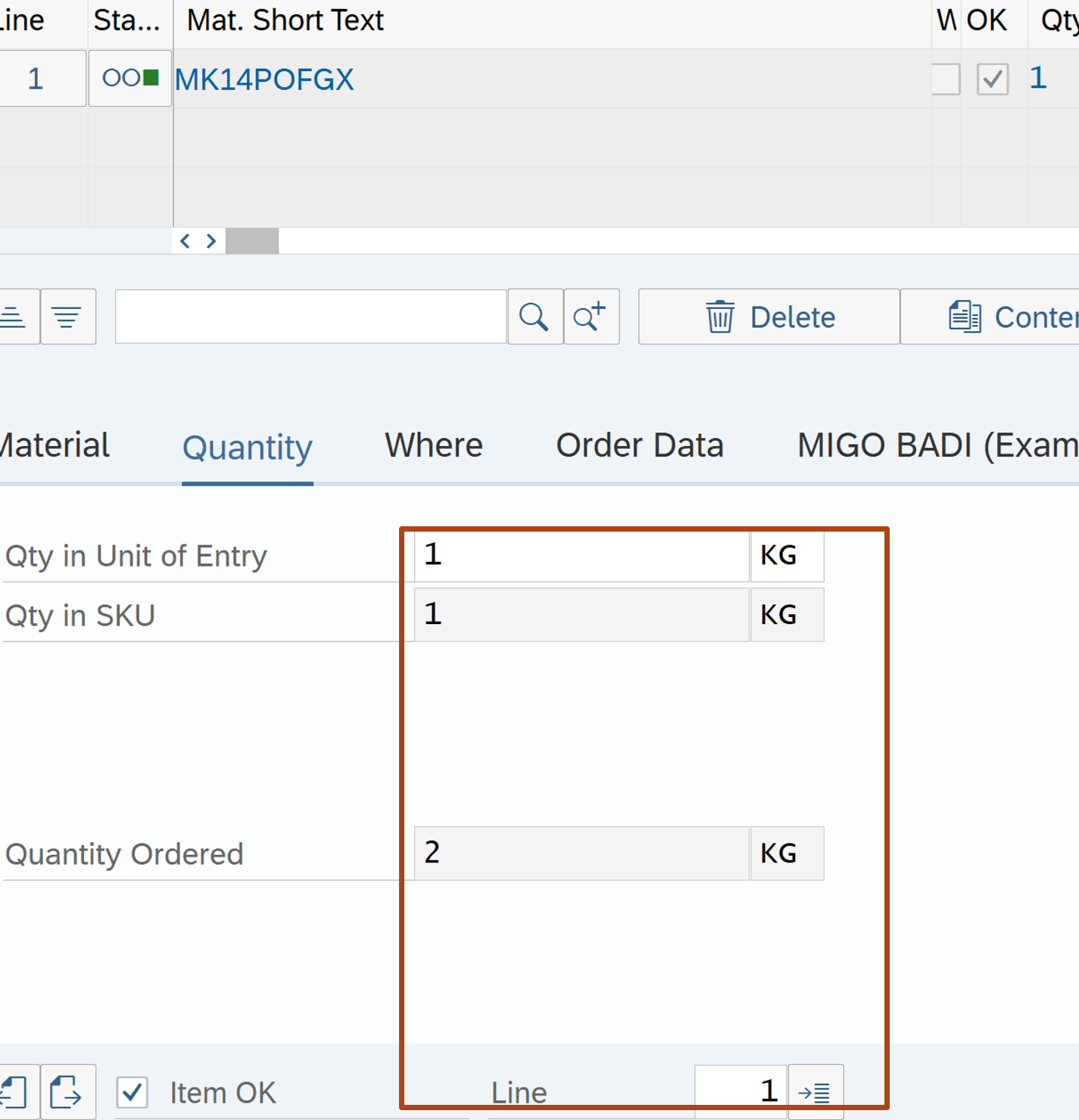

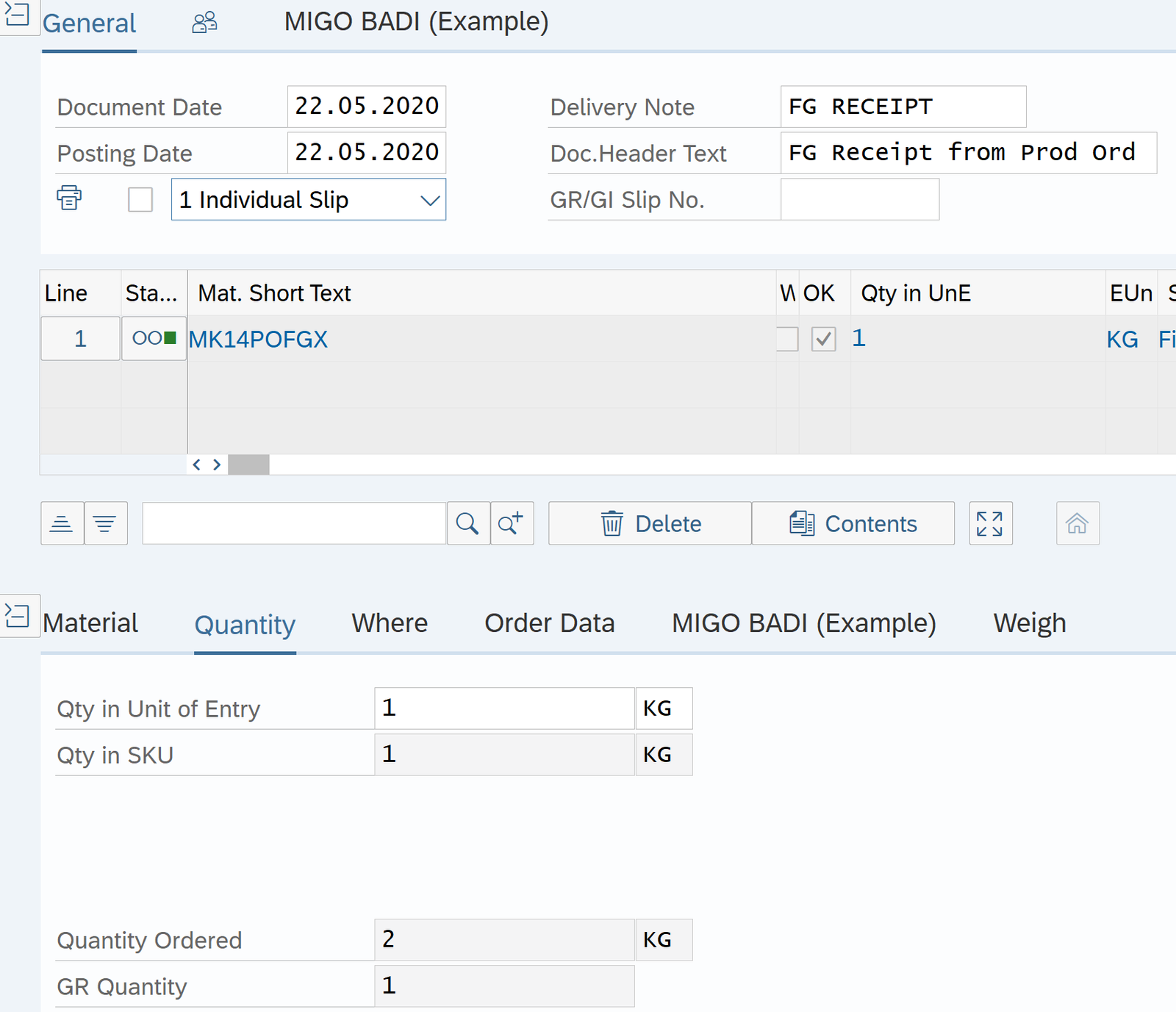

Tcode: MIGO

Received 1 KG of FG (Partial Completion of Production Order)

Material document 5000005113 posted

Verify actual order cost in CO03

GOTO – Cost – Analysis

Product Costing – 5 videos (Repeats explanation of cost splitting structure- Imp)

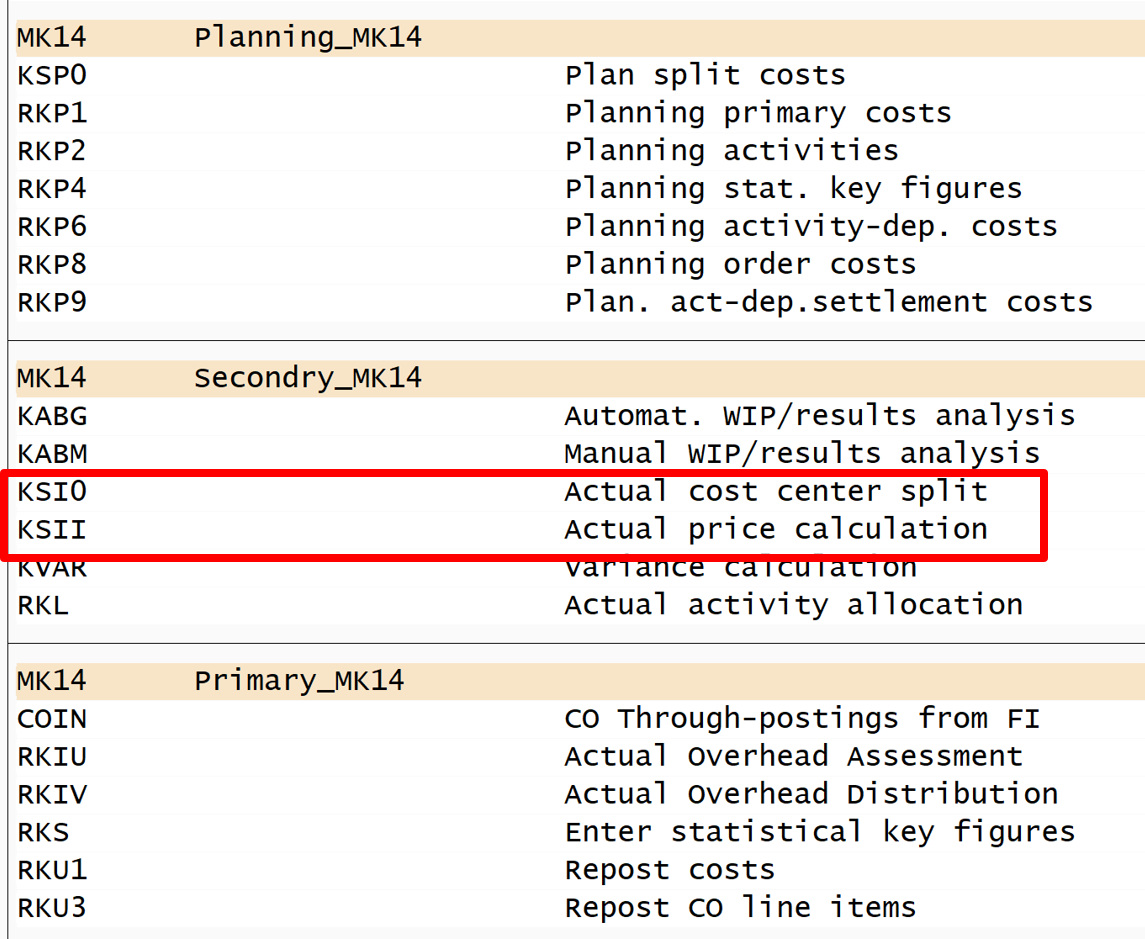

Assign CO business transaction KSIO and KSII to secondary postings Number range Tcode: KANK

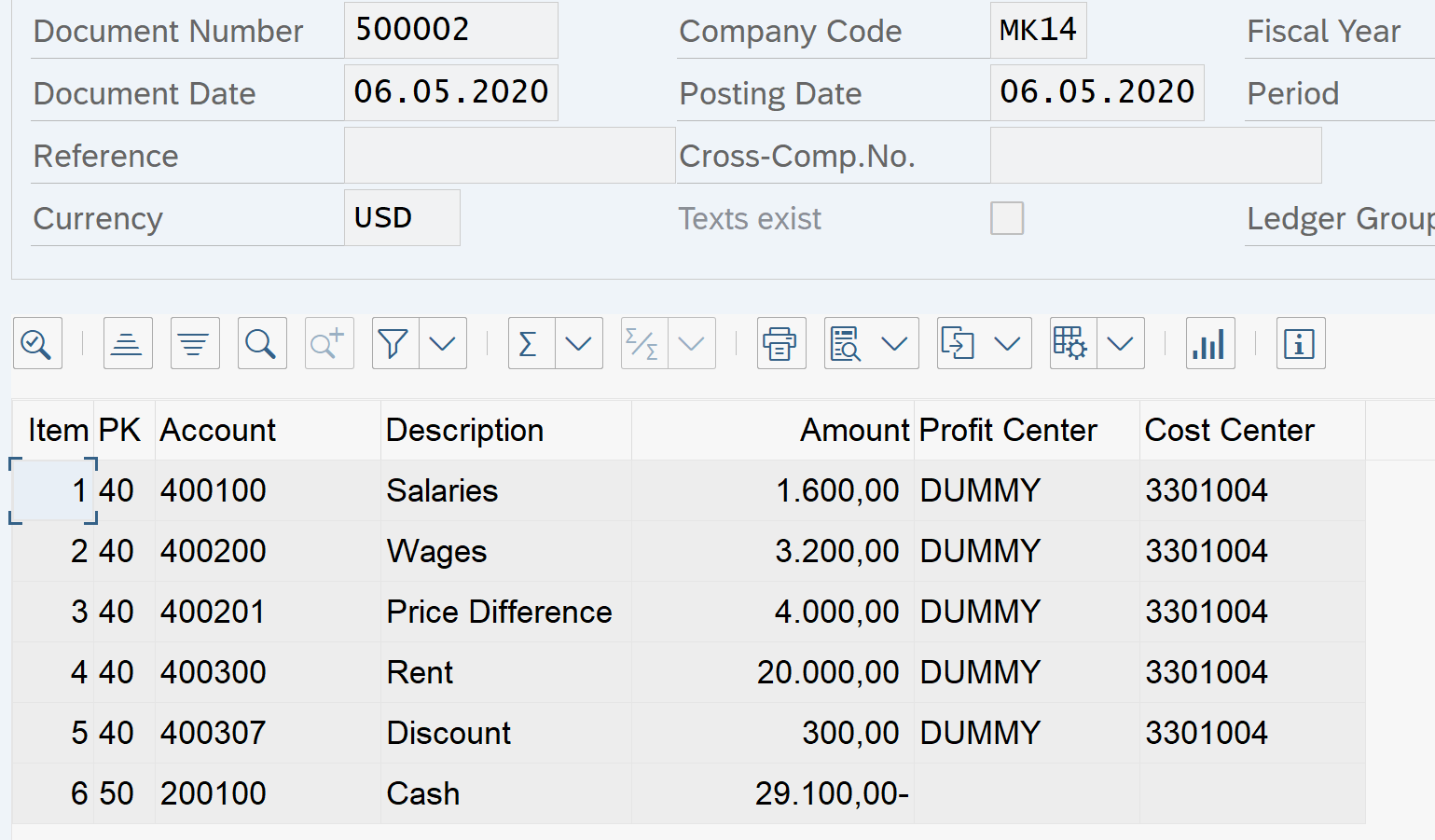

Tcode: FB50

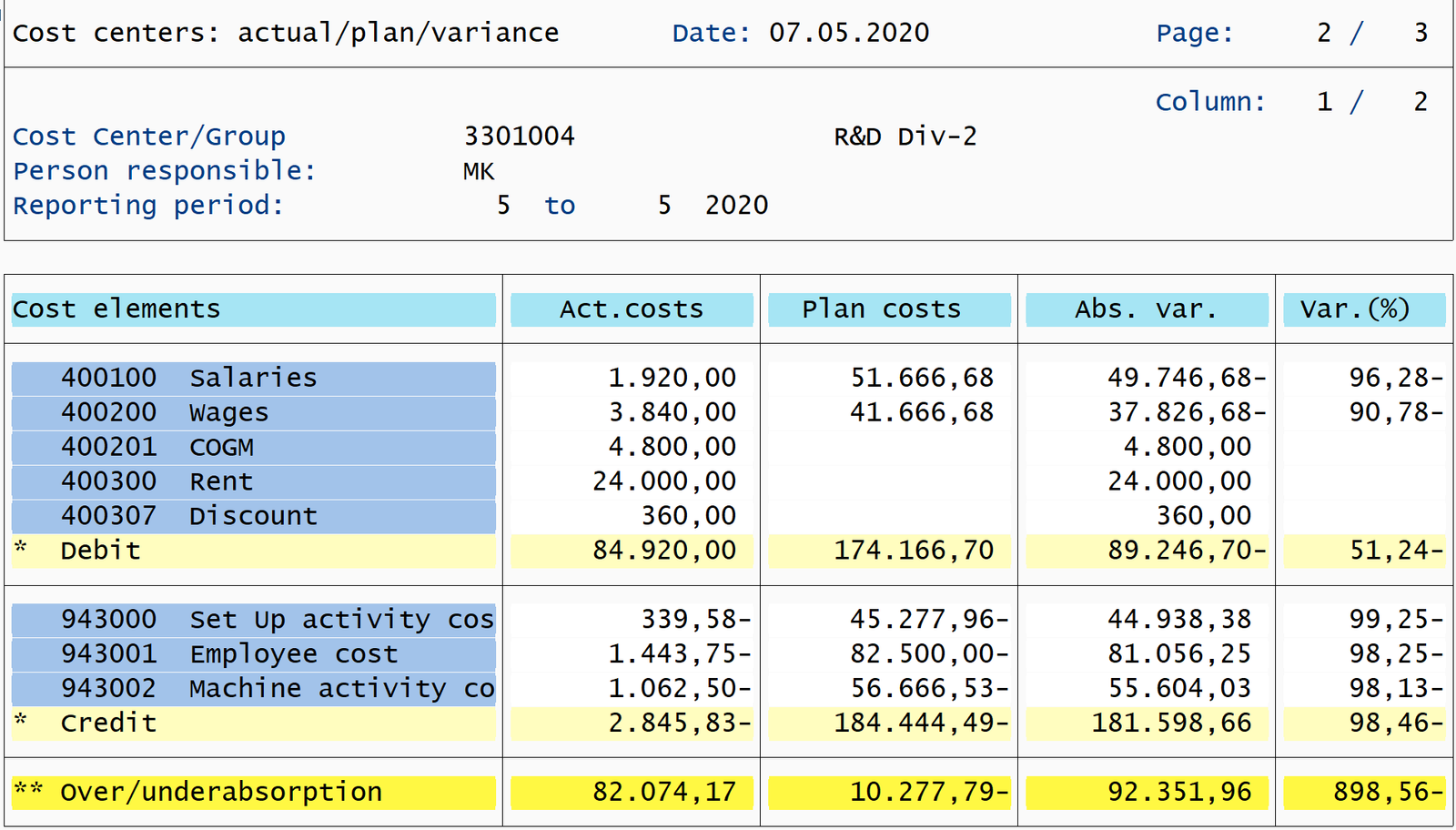

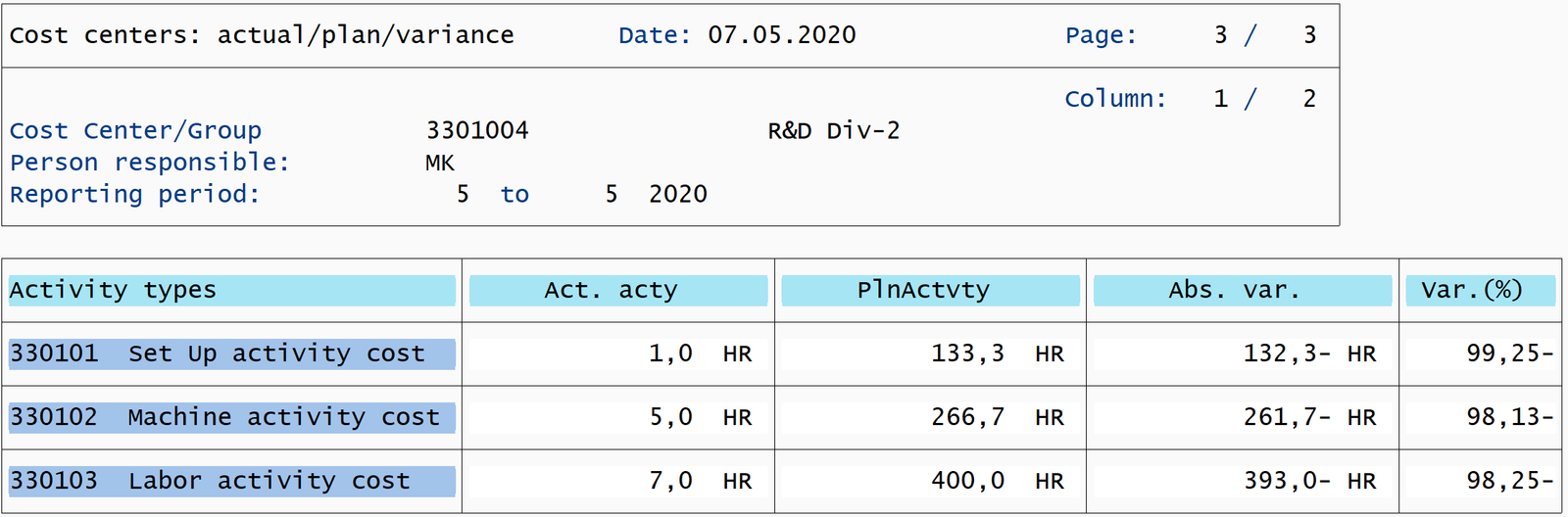

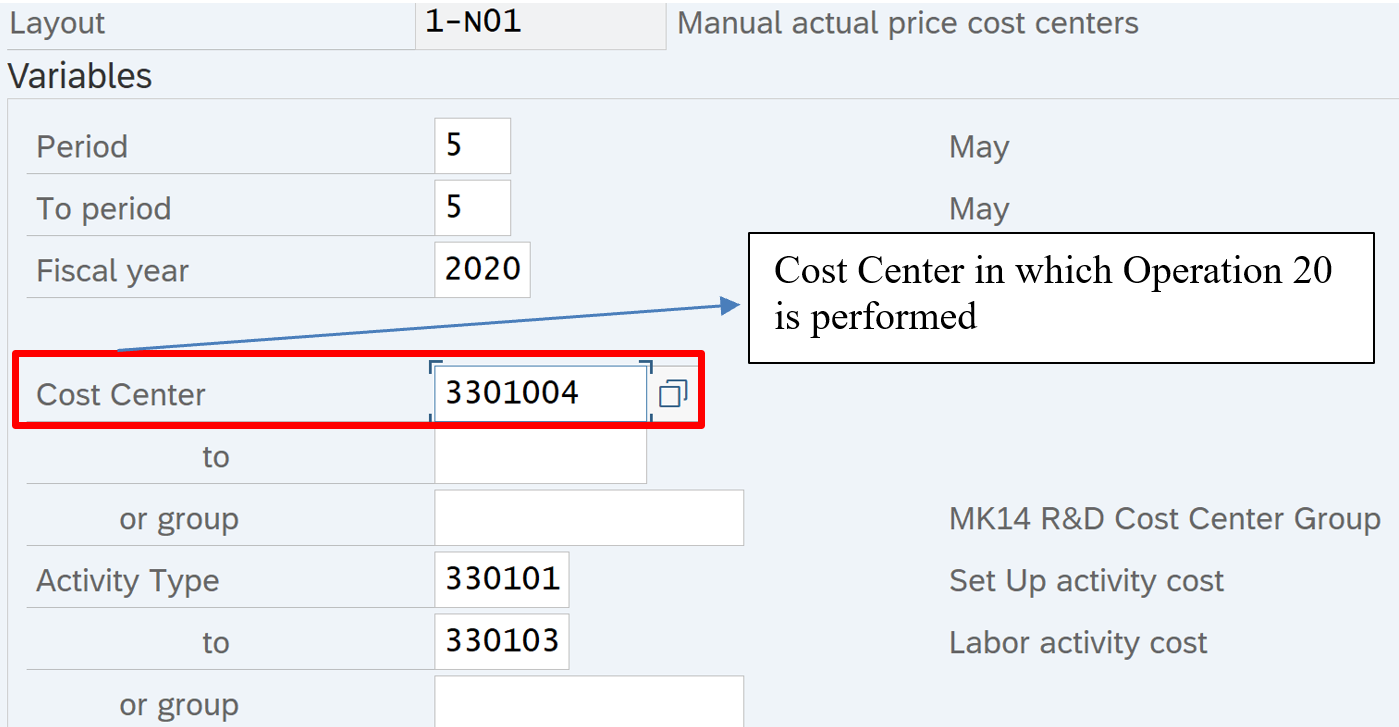

Verify Actual cost in Cost Center: S_ALR_87013611

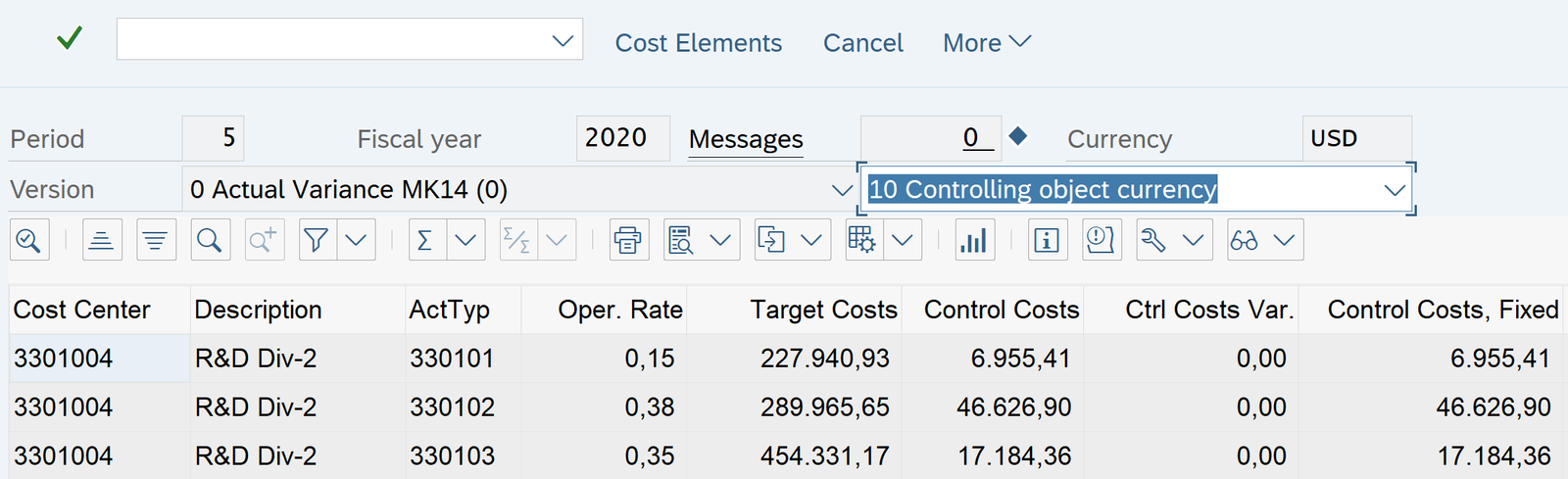

Tcode: KSS2

Control cost is another name for actual cost

Tcode: KSII

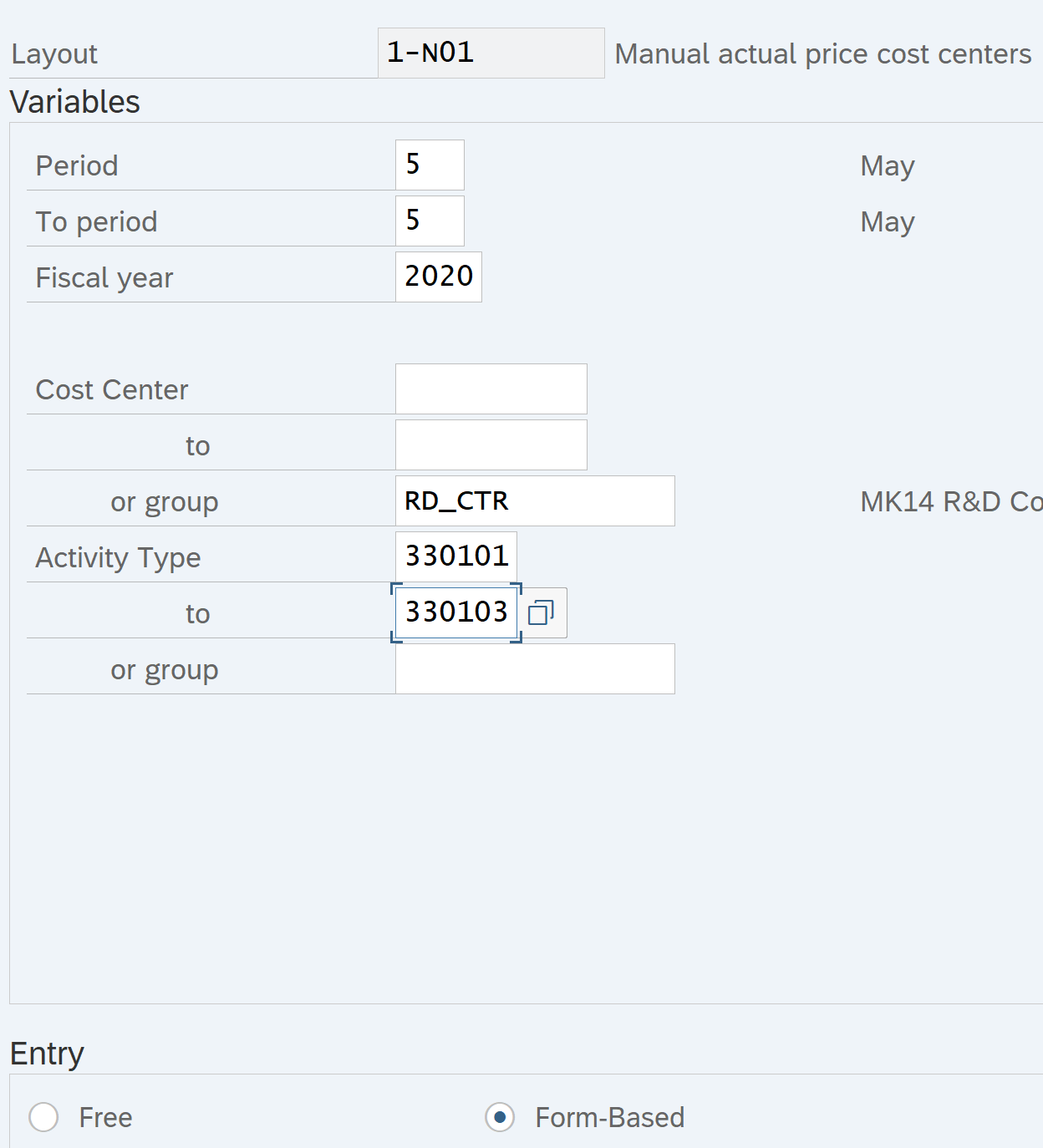

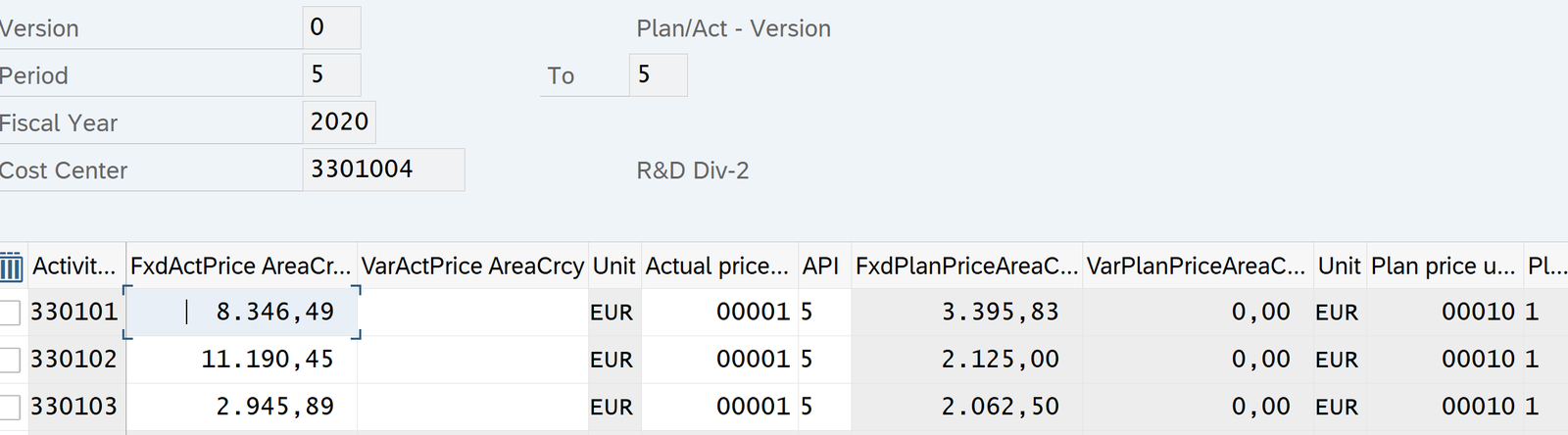

Check Activity Price per hour: KSBT

Tcode: KBK6

For the purpose of Product costing we will overwrite the system calculated actual price of activity per hour

Same as shown in KSII above. Changed to 15

Verify in Activity Price report: KSBT

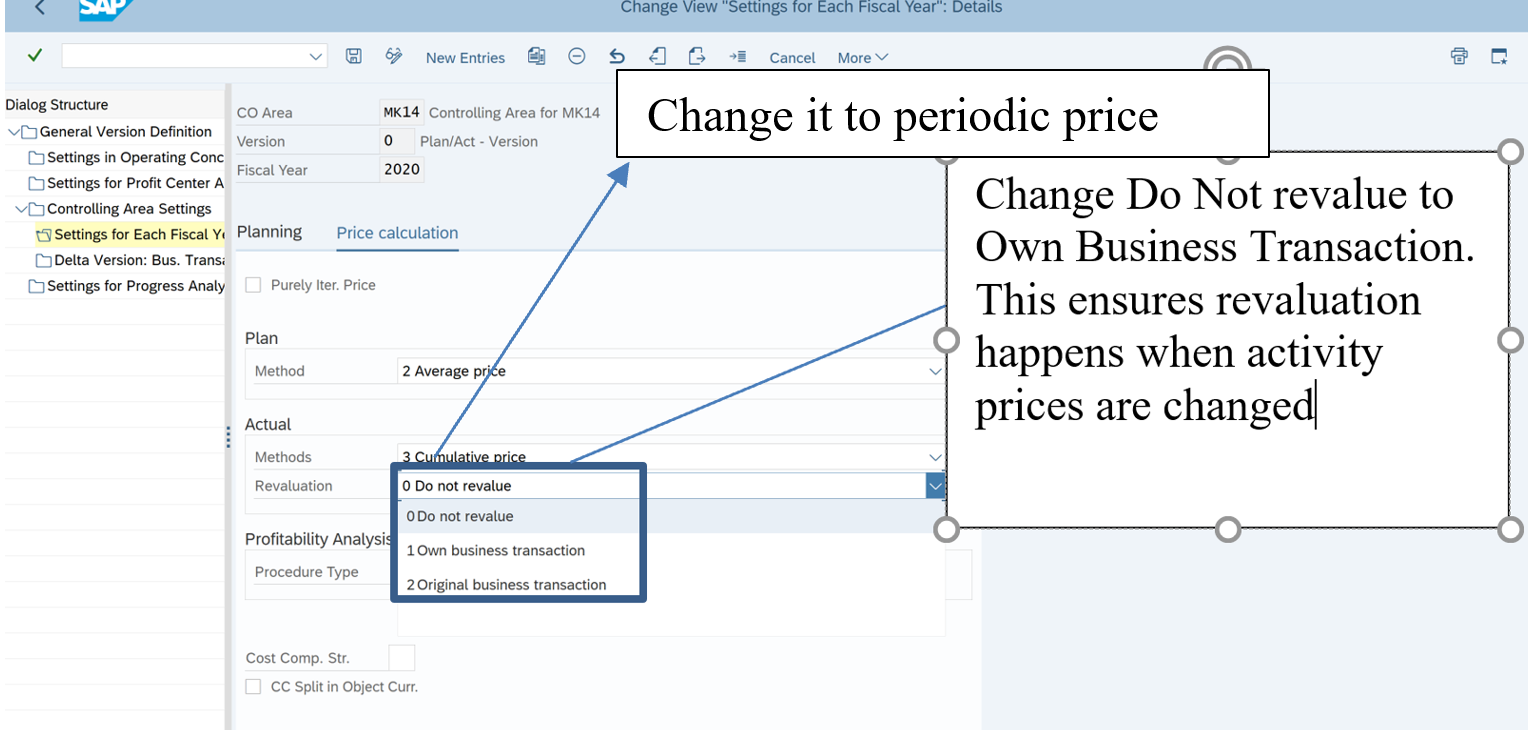

Tcode: OKEQ

Specify the CCS B1 created earlier here

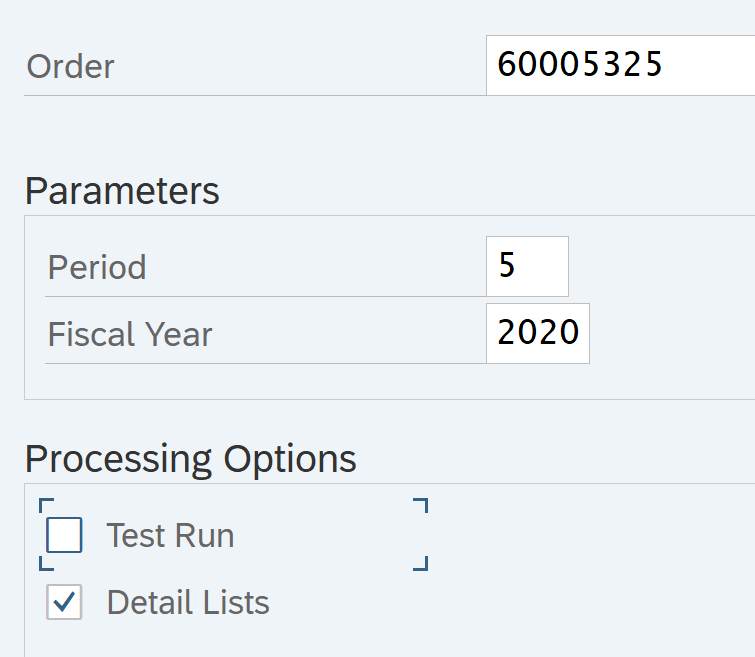

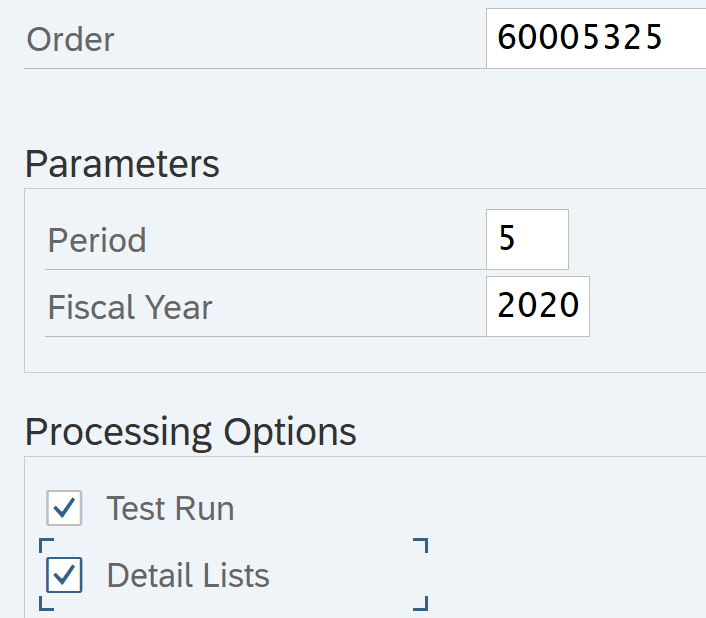

Tcode: MFN1 / CON2

Tcode: CO03

GOTO – Cost – Analysis

Tcode: KANK

Assign to secondary postings

Tcode: KGI2

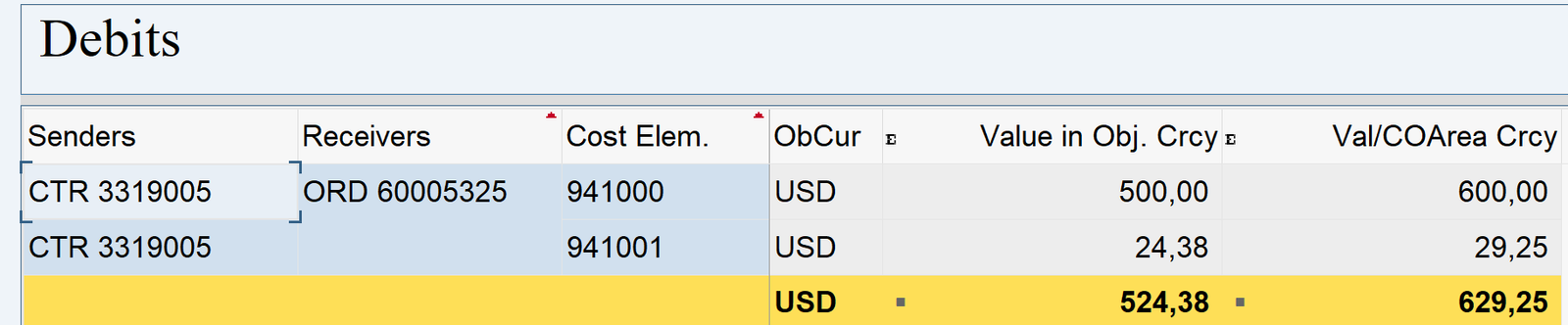

Now verify actual OH cost in Production Order: CO03

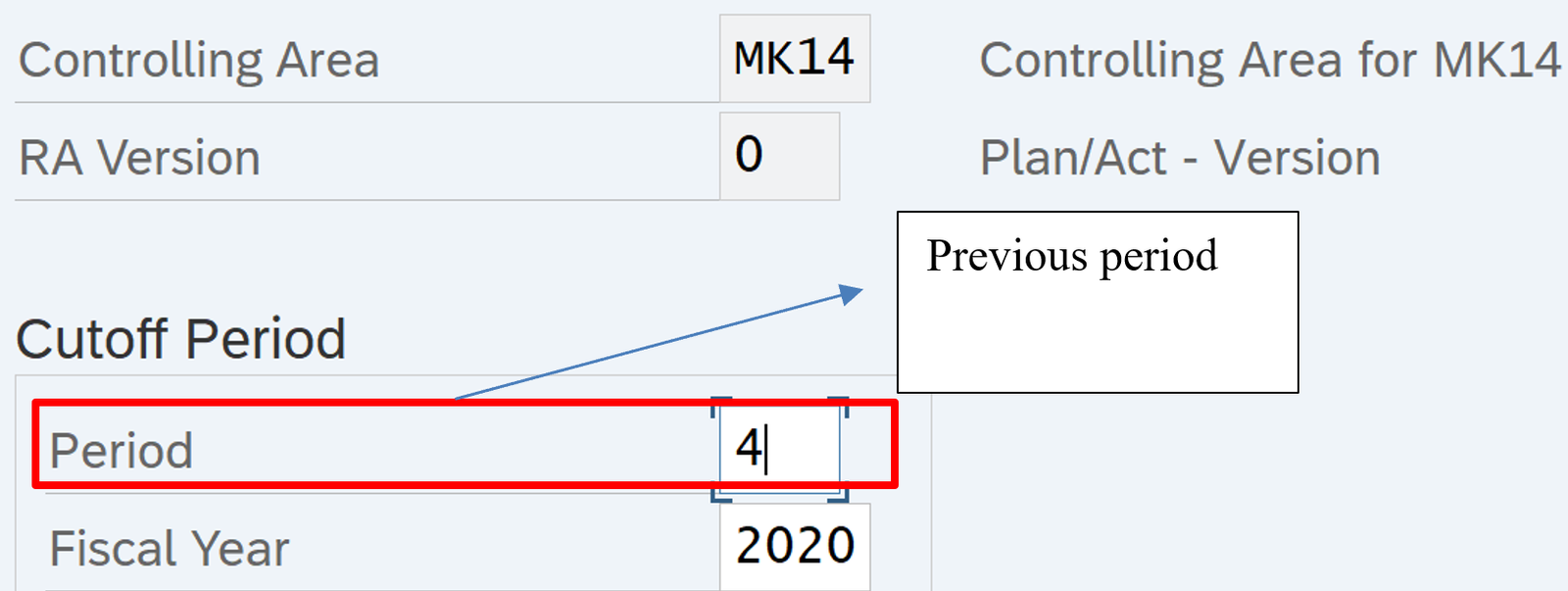

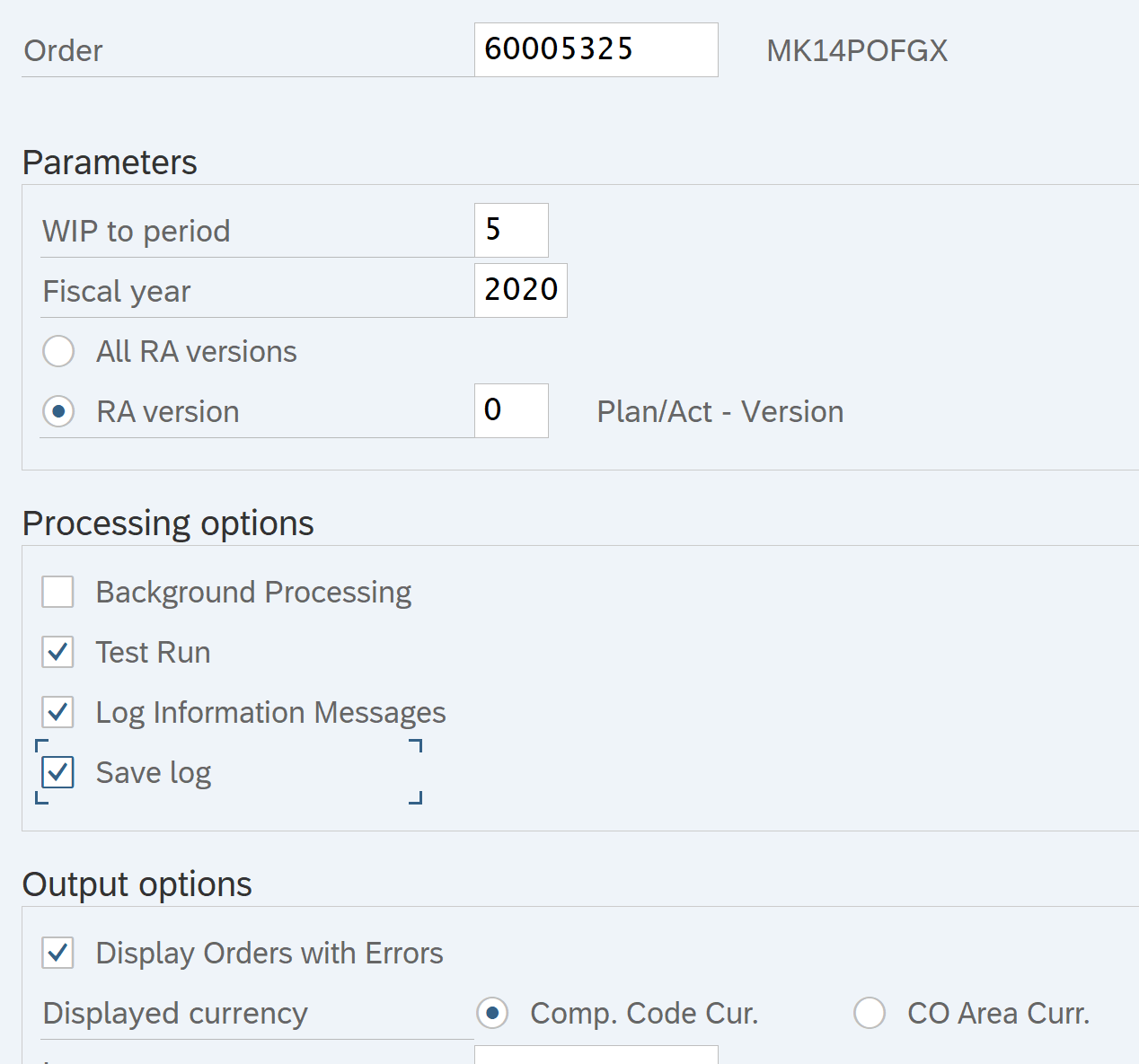

First step in calculating WIP is to cut off previous period

Tcode: KKA0

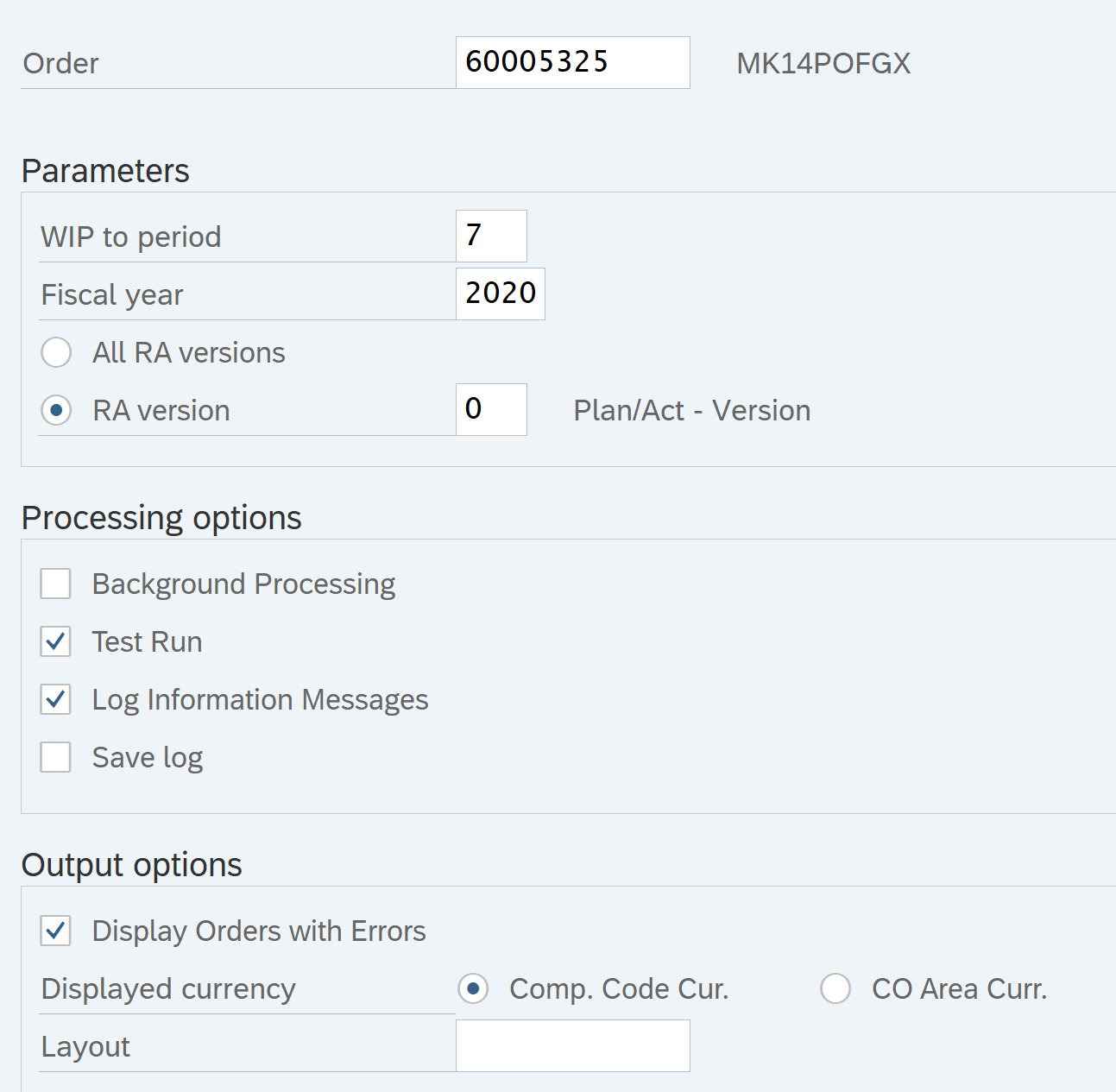

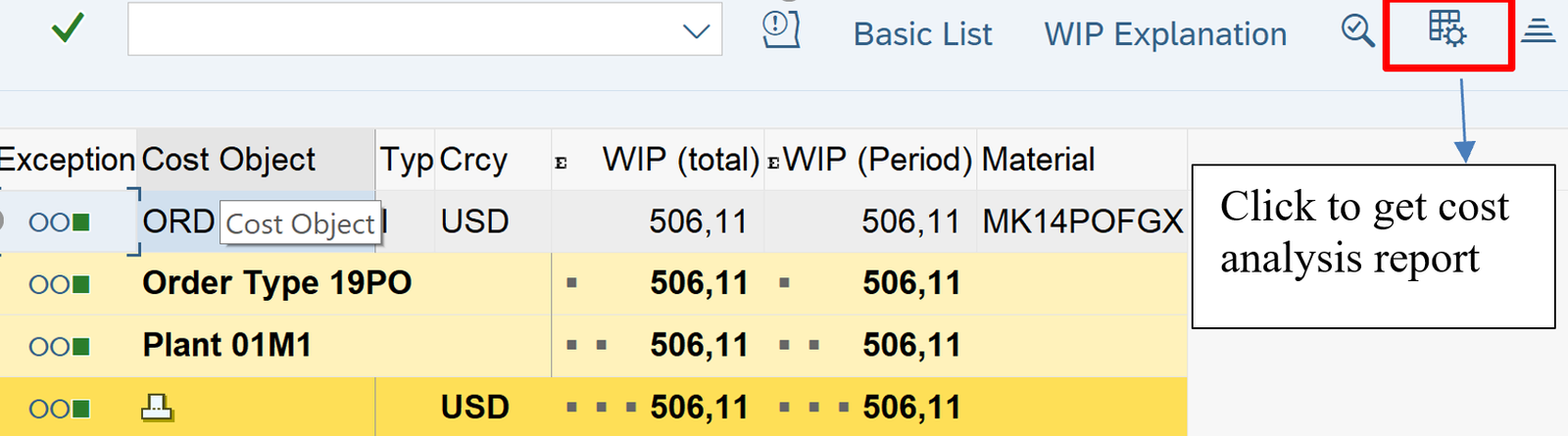

Tcode (Individual): KKAX

Collective: KKAO

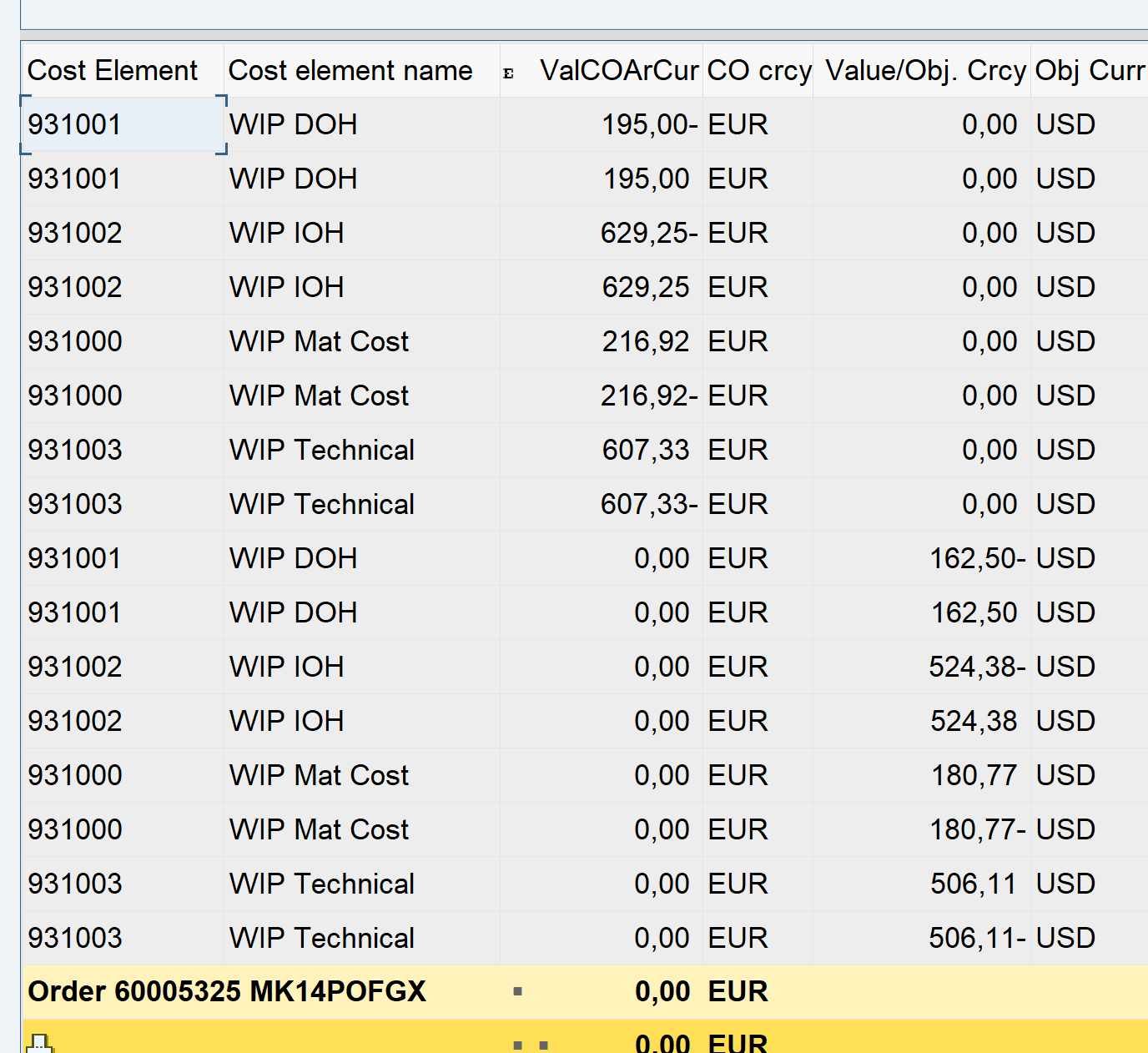

Tcode: KOB8

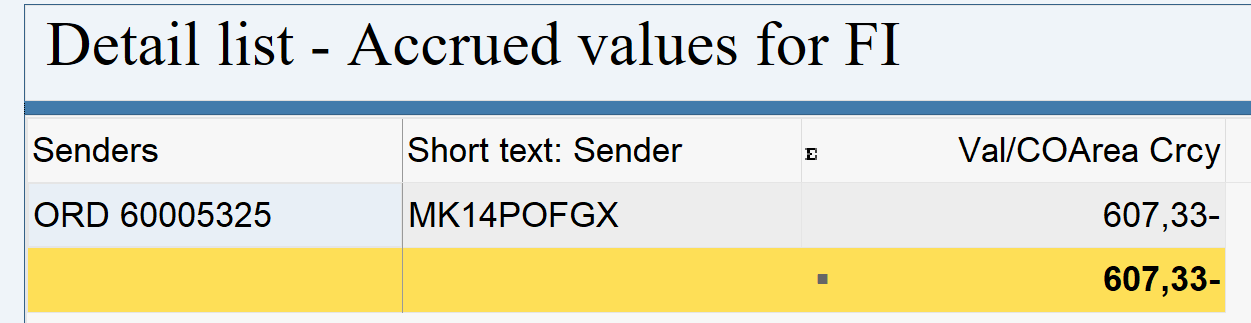

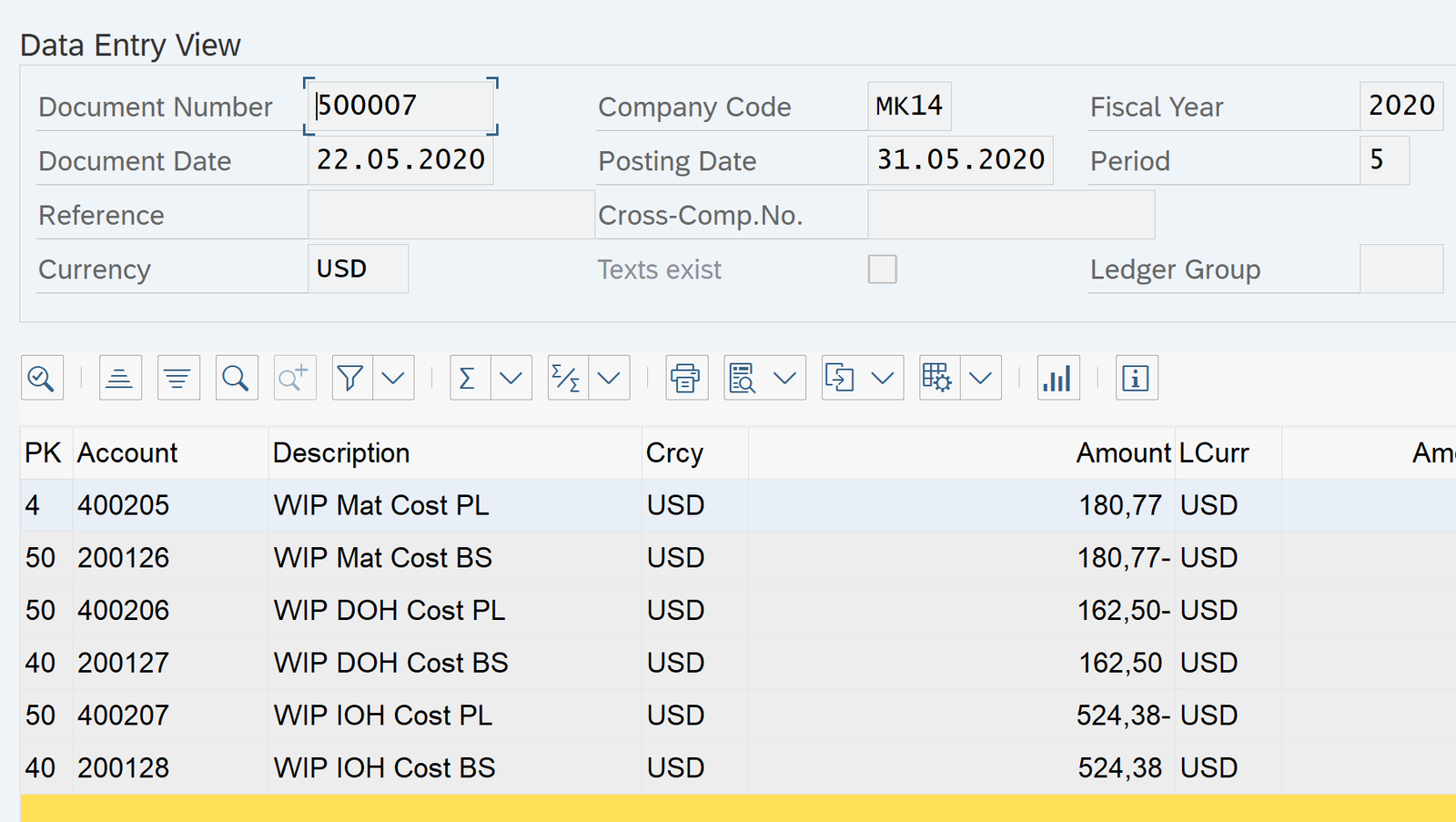

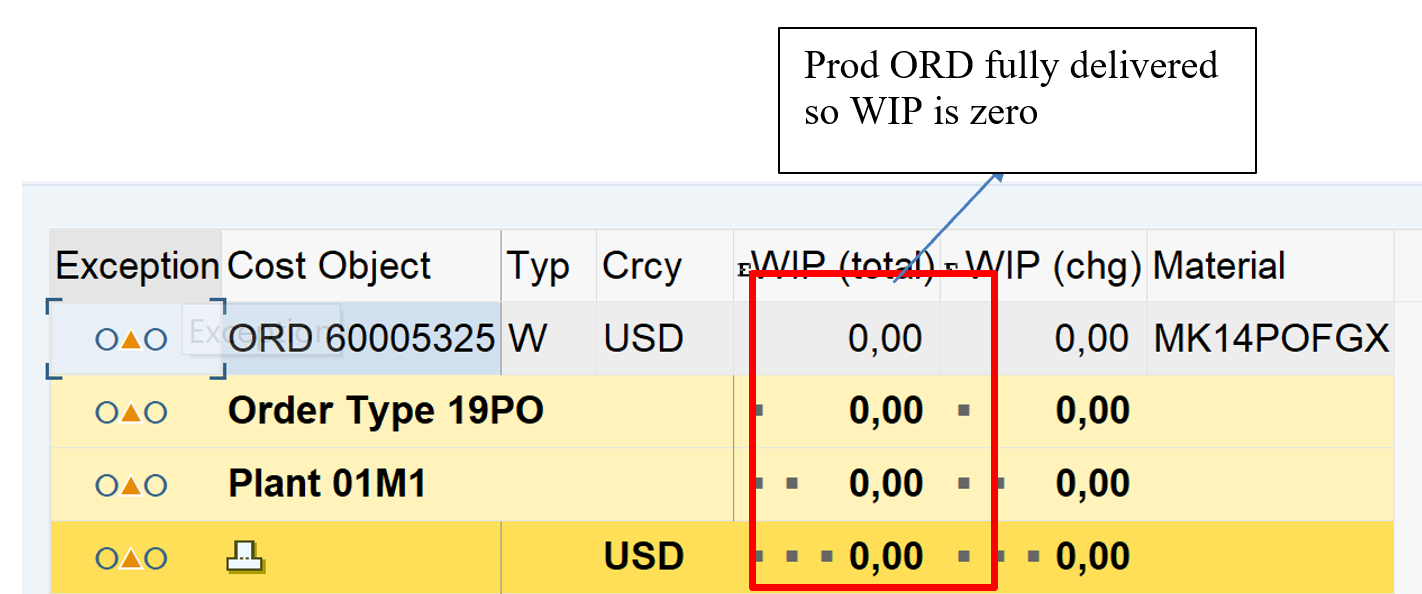

WIP Technical = WIP DOH + WIP IOH + WIP Mat Cost

It appears Month end posting made, so WIP is reversed

Note: Calculated when Order status is fully delivered or TECO

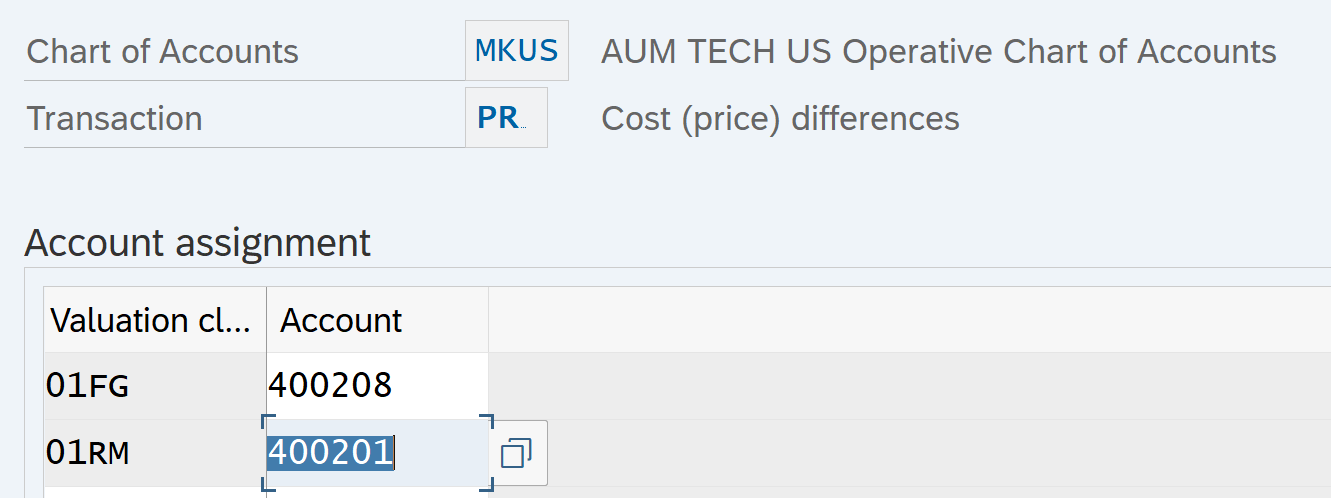

Tcode: FS00

GL: 400208

Tcode: OBYC

Transaction Key: PRD

Tcode: KANK

Business Transactions: KSOS, KSOP, KKKP, KKKS

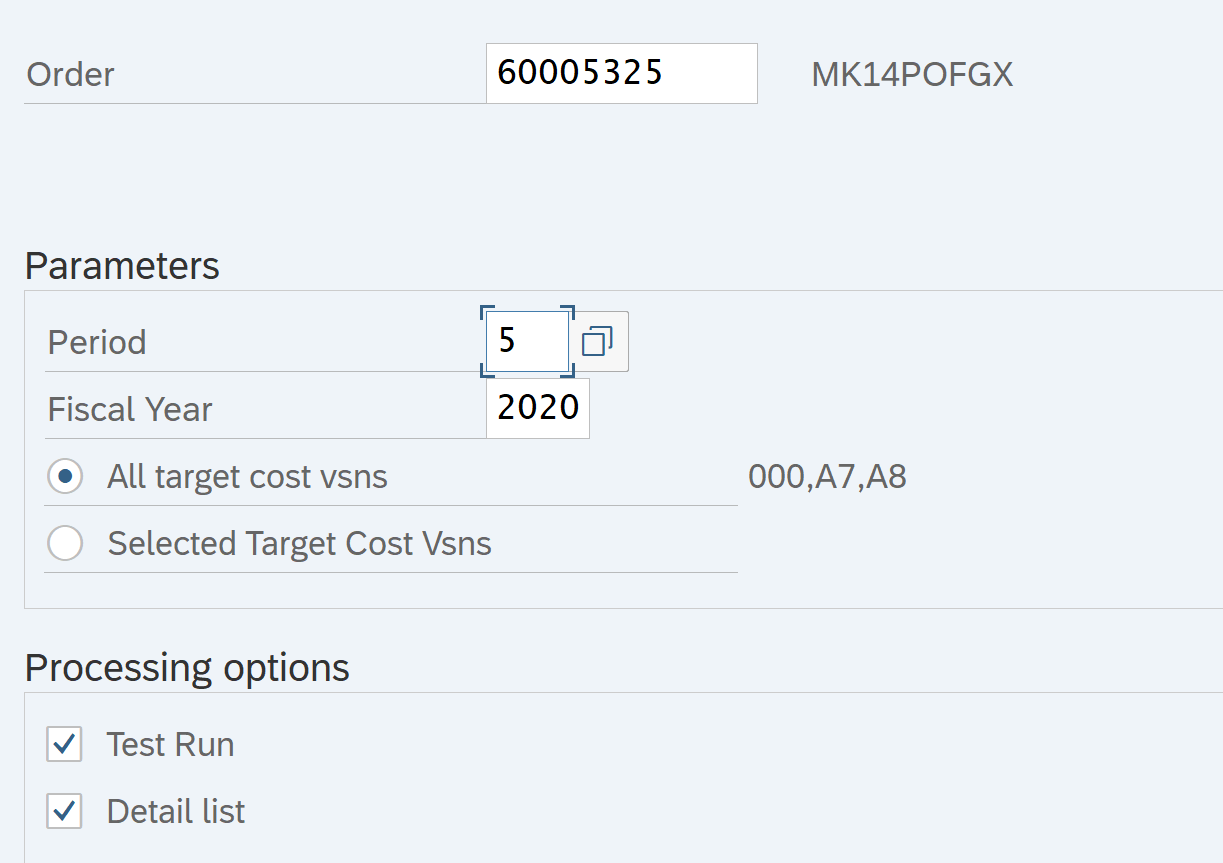

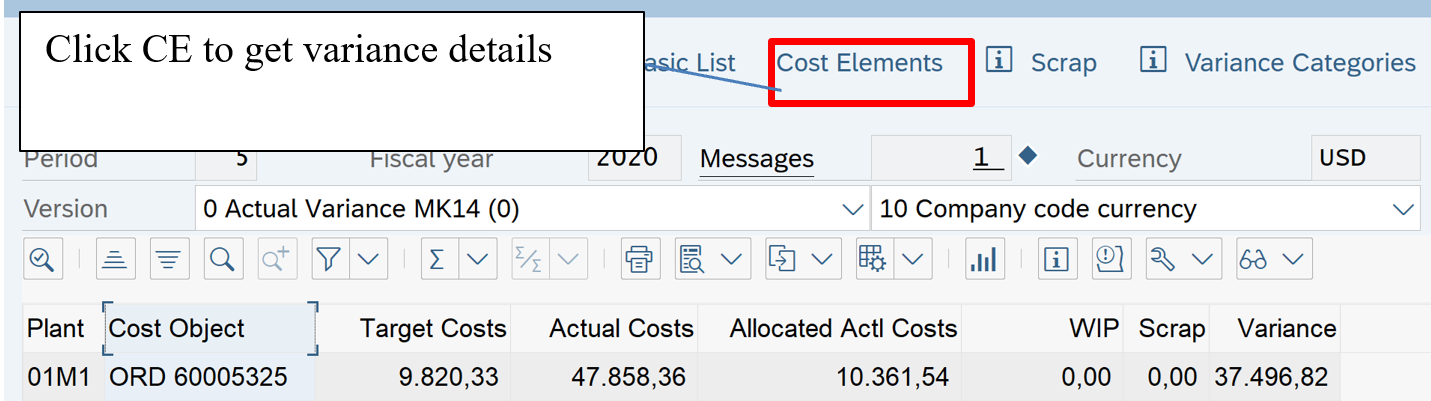

Tcode: KKS2

Before Variance calculation Production Order settlement has to be carried out

Individual Production Order: KO88

Collective Production Order: CO88

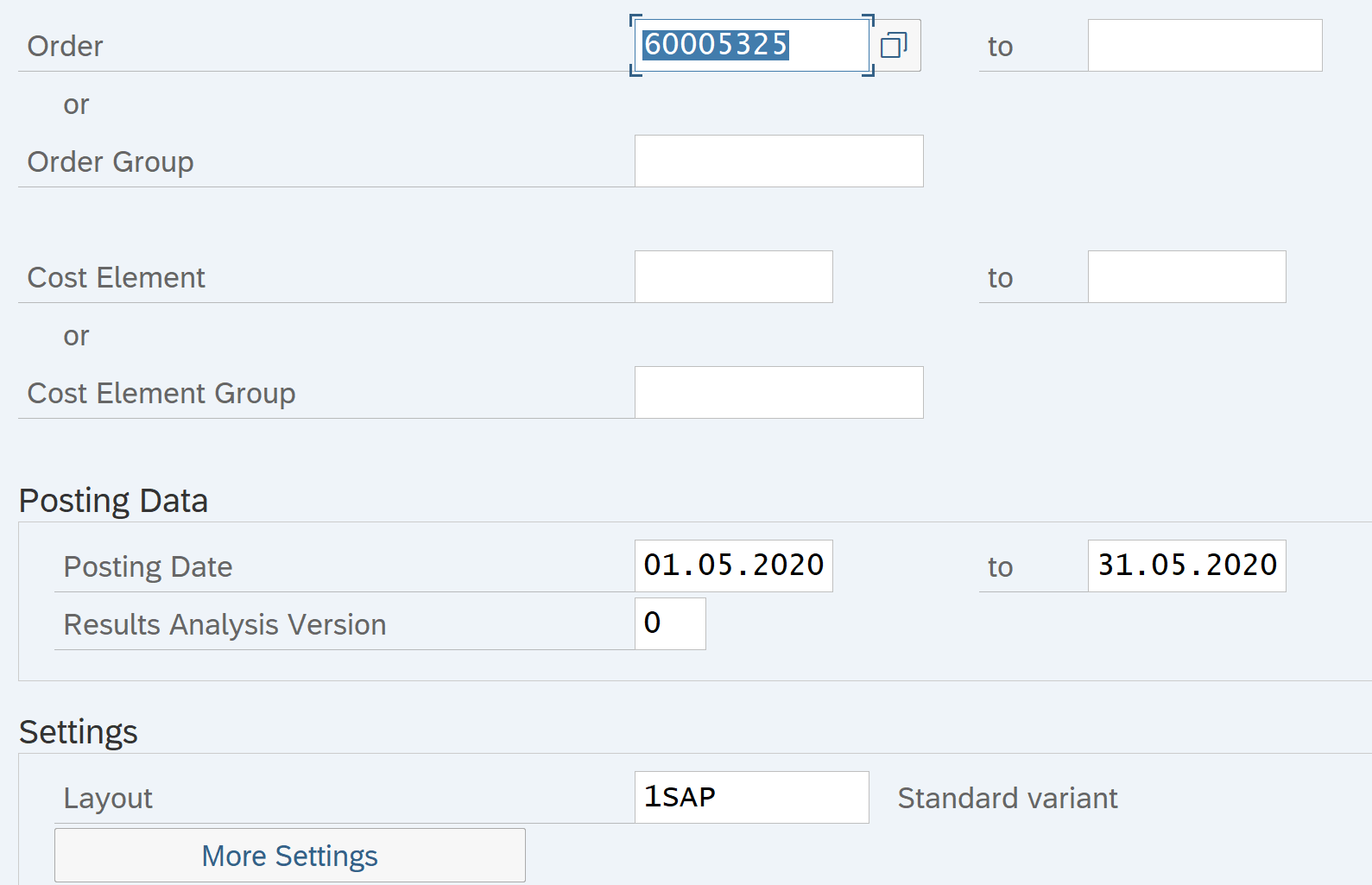

Display Production Order Settlement Doc : KSB5

During settlement WIP values transferred from CO to FI

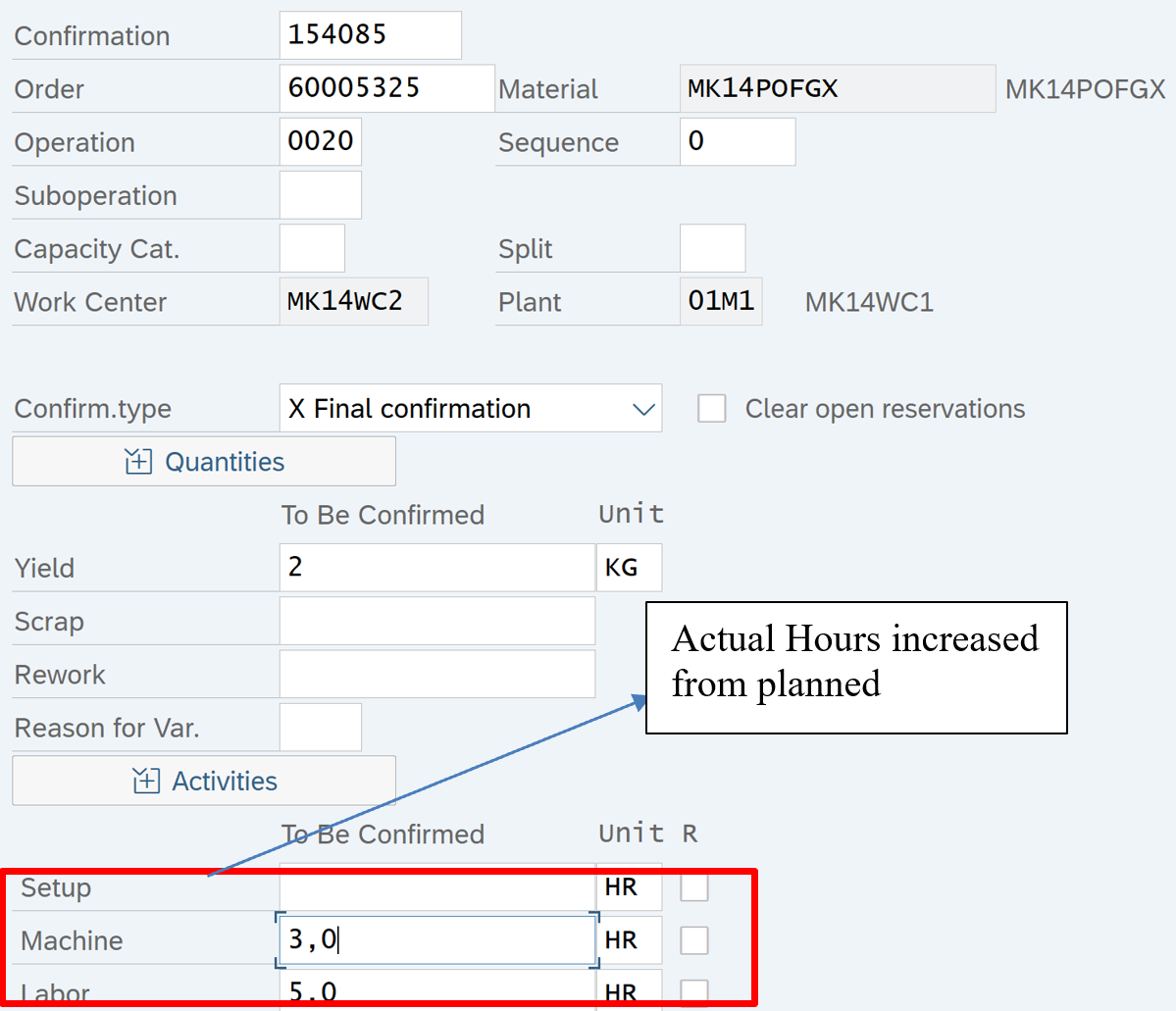

Tcode: CO11N

Enter and Save – Completes confirmation

Confirmation of order 60005325 saved

Production Order will have Actual Operation 20 cost posted to it

Tcode: MIGO

Prod Order: 60005325

Movement Type: 101

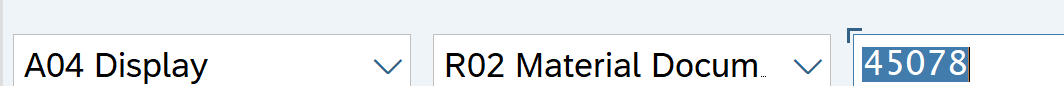

Receive Full Qty from the Production Order

Material document 45078 posted

Select Display in MIGO

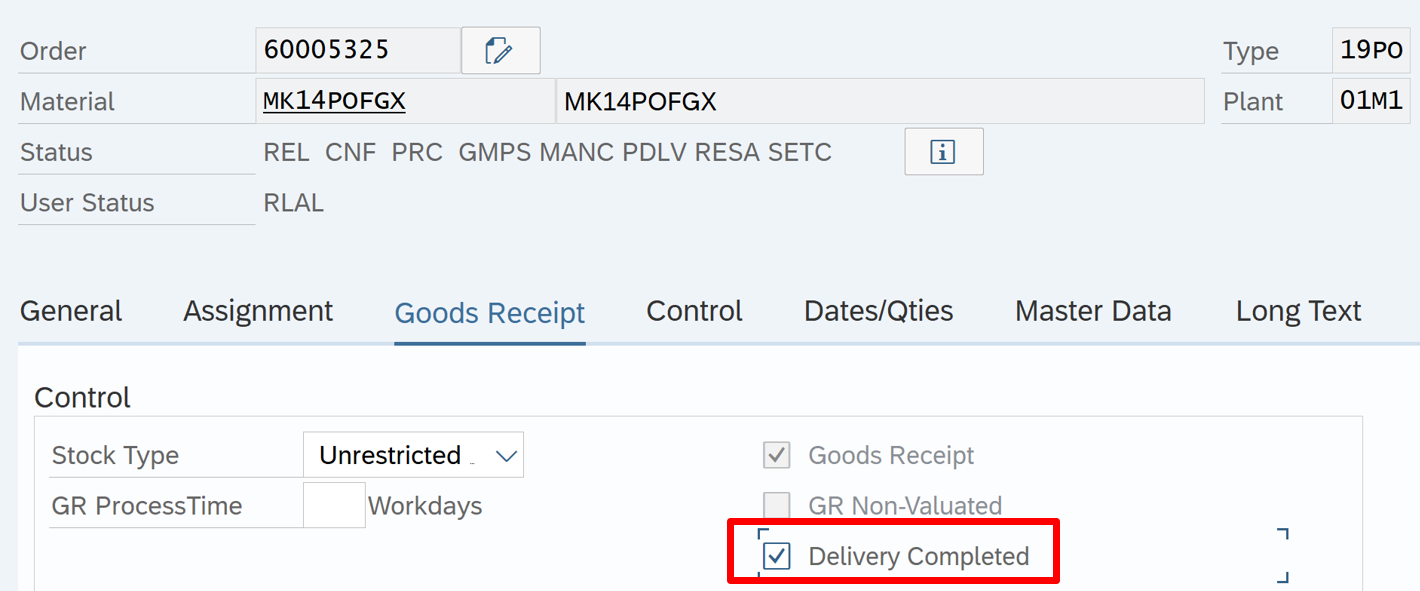

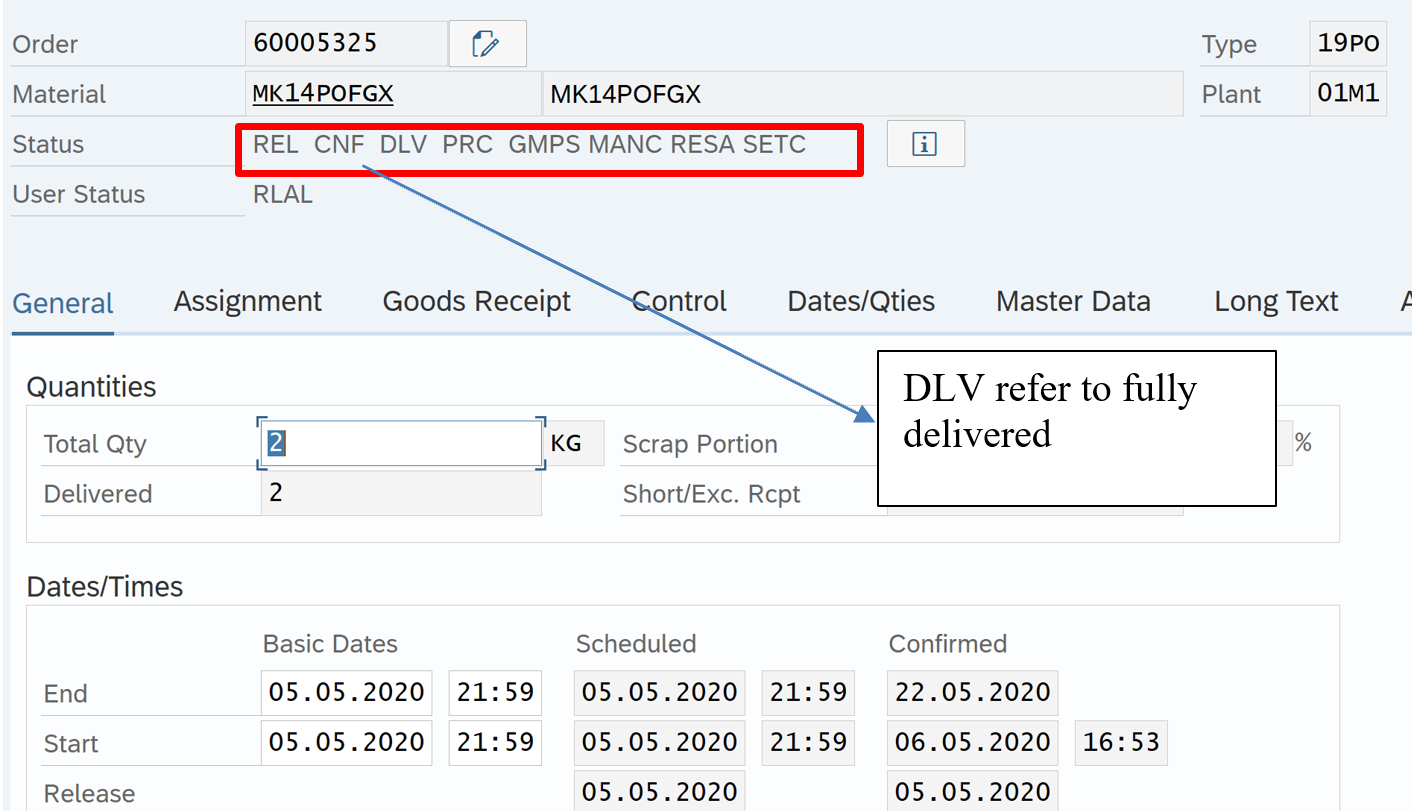

Tcode: CO02

Once the Production Order qty is fully issued, status update to Fully delivered

As Production Order status is Partially delivered, manually change it to fully deliver as below

Select Delivery Completed in the Goods Receipt tab and Save

Video 6

Manually enter actual activity Price: KBK6

System Calculation of Actual Activity price

Manual calculation of Planned activity Price: KP26

System Calculation of Planned Activity Price

- OKES

- OKEW

- KSS4

- KSPI

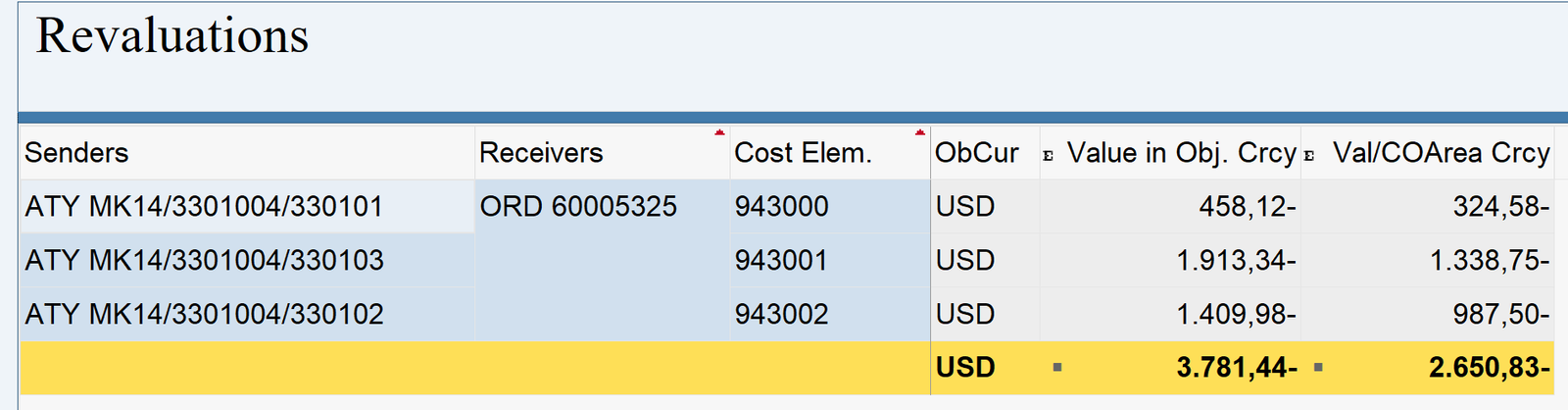

Revalue Operation Activities at actual price: MFN1

- Calculate Actual Over Heads

- Perform Month end cut off / period change for WIP: KKA0

- Perform WIP Calculation: KKAX

- Calculate Variance : KKS2

In this Month we manually maintain actual activity price as system calculated done in last month

Tcode: KBK6

Tcode: MFN1

Actual Price now have gone up

Check Production Order: CO03

Tcode: KGI2

Click Back arrow two times. Message Online processing completed. Than only it post to FI

Verify the cost in Production Order: CO03

Not required as same month

Please visit previous tutorial on Product Costing Business Process, Configuration in SAP

Please visit next tutorial on Profit Center Accounting

For Step by Step instruction to configure, test and understand Product Costing in SAP please join my SAP Controlling Course

Pingback: Course Material - AIERP2